A4 Mk2

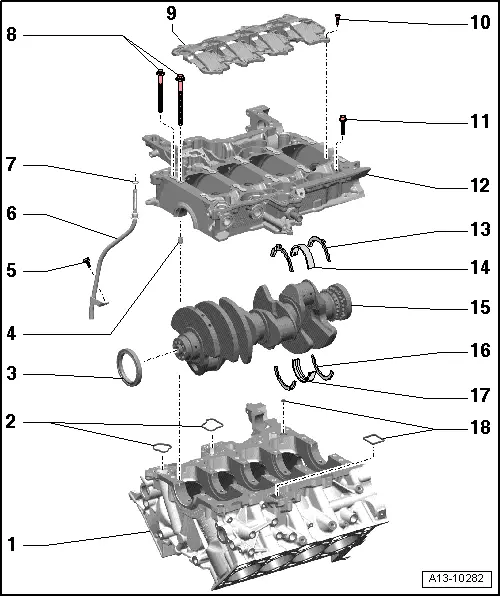

| Crankshaft - exploded view |

| 1 - | Cylinder block |

| q | Matched to -item 12- |

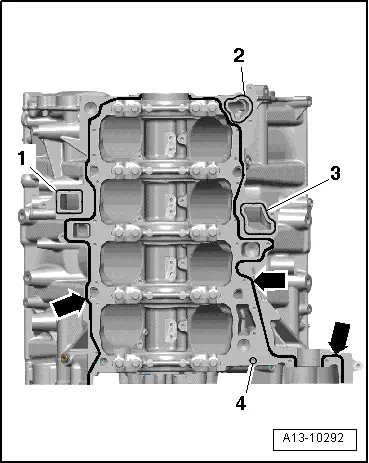

| q | Applying sealant onto cylinder block (for retaining frame) → Fig. |

| 2 - | Gaskets |

| q | Renew |

| 3 - | Oil seal for crankshaft (pulley end) |

| q | Renewing → Chapter |

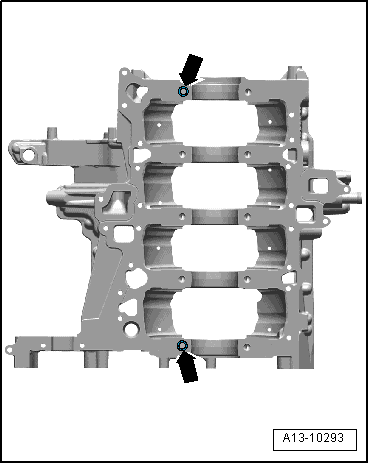

| 4 - | Dowel sleeve |

| q | 2x |

| q | Insert in retaining frame |

| q | Installation position → Fig. |

| 5 - | 9 Nm |

| 6 - | Guide tube for oil dipstick |

| 7 - | O-ring |

| q | Renew |

| 8 - | Bolts |

| q | For retaining frame |

| q | Renew |

| q | Different bolt lengths |

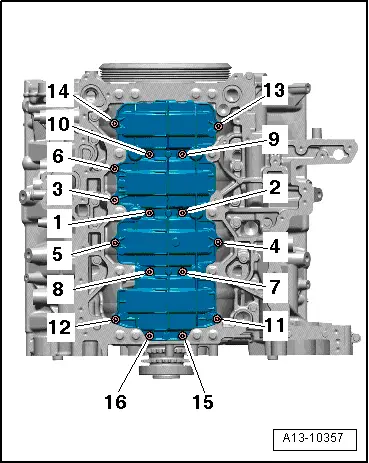

| q | Tightening sequence → Fig. |

| 9 - | Baffle plate |

| 10 - | 9 Nm |

| q | Tightening sequence → Fig. |

| 11 - | Bolt |

| q | For sealing surfaces: cylinder block/retaining frame |

| q | Different bolt lengths |

| q | Tightening sequence → Fig. |

| 12 - | Retaining frame |

| q | Matched to -item 1- |

| q | Applying sealant onto cylinder block (for retaining frame) → Fig. |

| q | Tightening sequence for securing bolts → Fig. |

| 13 - | Thrust washer |

| q | Only fitted on 4th crankshaft bearing |

| q | Oil grooves face outwards |

| q | Make sure it engages in retaining frame |

| q | Measuring axial clearance of crankshaft → Chapter |

| 14 - | Bearing shell |

| q | For retaining frame (without oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| q | Bearing shells worn down to the base layer must be renewed |

| q | Install new bearing shells for retaining frame with correct coloured markings |

| New crankshafts → Chapter |

| Used or machined crankshafts → Chapter |

| 15 - | Crankshaft |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| q | Crankshaft dimensions → Chapter |

| 16 - | Thrust washer |

| q | Only fitted on 4th crankshaft bearing |

| q | Oil grooves face outwards |

| q | Measuring axial clearance of crankshaft → Chapter |

| 17 - | Bearing shell |

| q | For cylinder block (with oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| q | Bearing shells worn down to the base layer must be renewed |

| q | Install new bearing shells for the cylinder block with the correct coloured markings |

| New crankshafts → Chapter |

| Used or machined crankshafts → Chapter |

| 18 - | Gaskets |

| q | Renew |

|

|

|

|

|

|

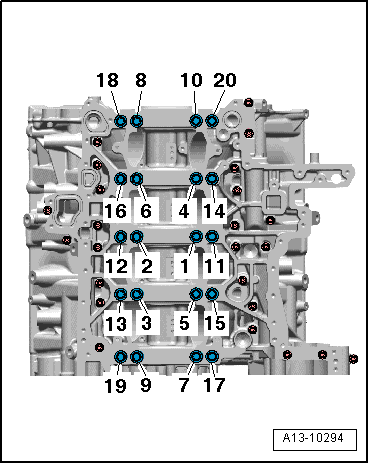

| Stage | Bolts | Tightening torque/tightening angle |

| 1. | -1 … 10- | 30 Nm |

| 2. | -11 … 20- | 20 Nm |

| 3. | -1 … 10- | 50 Nm |

| 4. | -11 … 20- | 30 Nm |

| 5. | -1 … 20- | turn 90° further |

|