A4 Mk2

| Pistons and conrods - exploded view of components |

Note

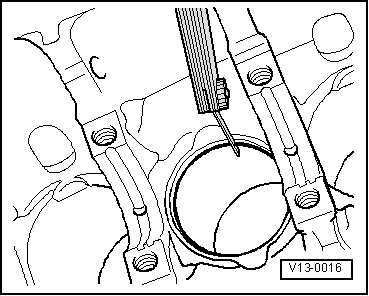

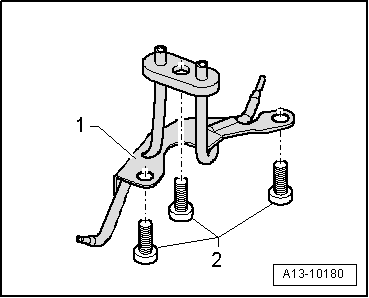

Note| Oil spray jet for piston cooling → Fig.. |

| 1 - | Conrod bolt, 30 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but do not turn further |

| 2 - | Conrod bearing cap |

| q | Do not interchange |

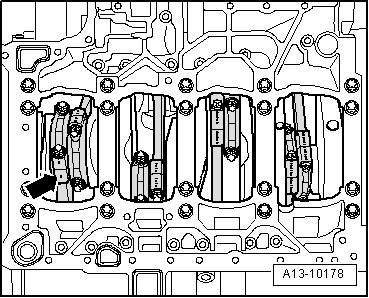

| q | Mark cylinder allocation with a coloured pen -B- → Fig. |

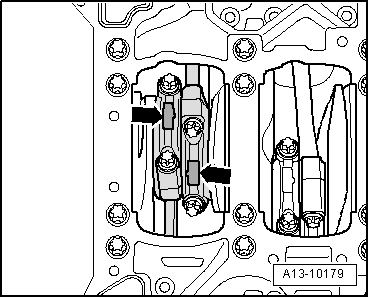

| q | Note when fitting bearing cap: the wide contact shoulder -A- must point towards same side on conrod and conrod bearing cap |

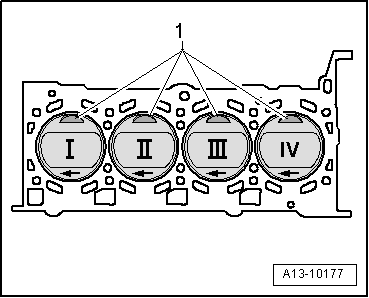

| q | Installation position of conrod pairs → Fig. |

| 3 - | Bearing shells |

| q | Ensure that retaining lugs are securely seated. |

| q | Do not interchange used bearing shells (mark accordingly, but not on the running surface) |

| q | Measuring radial clearance → Chapter |

| q | To measure radial clearance, tighten bolts → Item to 30 Nm but do not turn further |

| q | There are oversized bearings available for machined crankshaft conrod journals → Parts catalogue |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder allocation in colour -B- → Fig. |

| q | Note when fitting bearing cap: the wide contact shoulder -A- must point towards same side on conrod and conrod bearing cap |

| q | Installation position of conrod pairs → Fig. |

| q | Axial clearance for each conrod pair (when new): 0.20 … 0.38 mm |

| q | Wear limit (axial clearance): 0.60 mm |

| q | Measuring radial clearance → Chapter |

| 5 - | Piston pin |

| q | If difficult to move, heat piston to approx. 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 6 - | Circlip |

| 7 - | Piston |

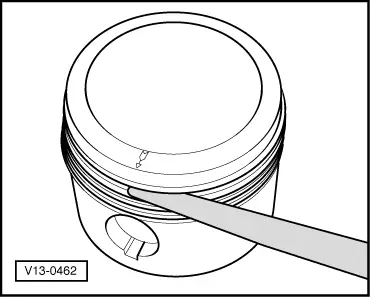

| q | Installation position for piston → Fig. |

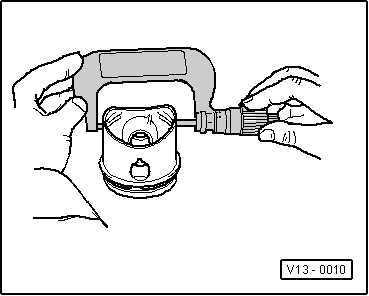

| q | Piston and cylinder dimensions → Chapter |

| q | Checking → Fig. |

| q | Install using piston ring clamp |

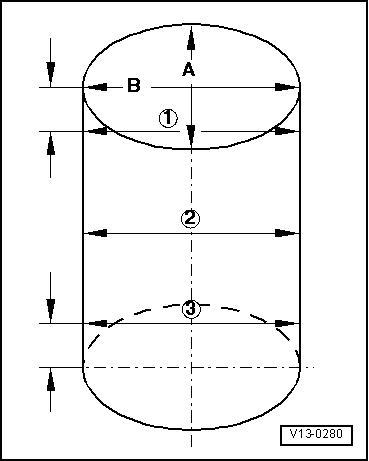

| q | Measuring cylinder bore → Fig. |

| 8 - | Piston rings |

| q | Offset gaps by 120° |

| q | Use piston ring pliers to remove and install |

| q | Marking “TOP” or side with identification mark must face piston crown |

| q | Measuring ring gap → Fig. |

| q | Measuring ring-to-groove clearance → Fig. |

| Piston ring (in mm) | New | Wear limit |

| 1st compression ring | 0.25 … 0.40 | 0.8 |

| 2nd compression ring | 0.20 … 0.40 | 0.8 |

| Oil scraper ring | – | 0.4 |

|

|

| Piston ring (in mm) | New | Wear limit |

| 1st compression ring | 0.04 … 0.08 | 0.20 |

| 2nd compression ring | 0.005 … 0.045 | 0.20 |

| Oil scraper ring | 0.01 … 0.05 | 0.15 |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|