| –

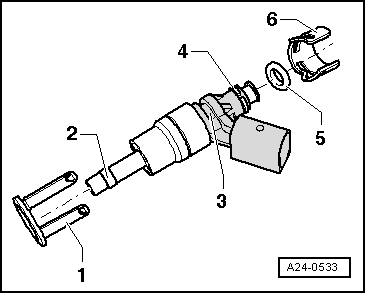

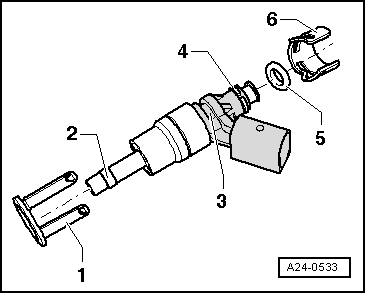

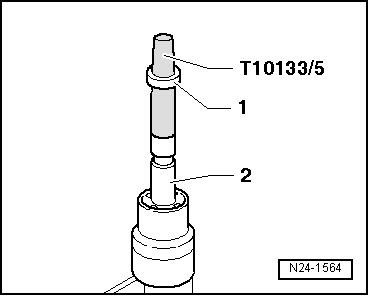

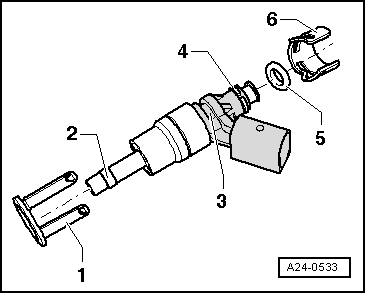

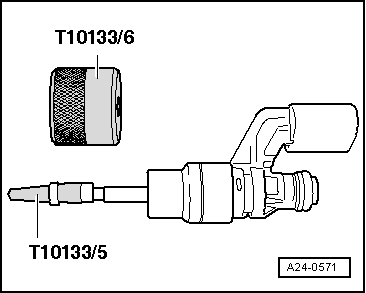

| Illustration shows injector assembly |

| 1 - | Radial compensation element, renew if damaged |

| 2 - | Combustion chamber ring seal (teflon ring seal) - renew; when fitting, do not grease ring or use any other lubricant |

| 4 - | Spacer ring (renew if damaged) |

| 5 - | O-ring (renew; apply thin coating of clean engine oil prior to installation) |

| 6 - | Support ring (via this support ring, fuel rail exerts force which secures injector in cylinder head) |

| –

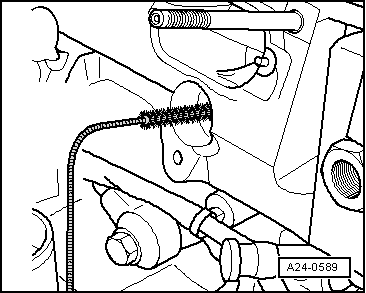

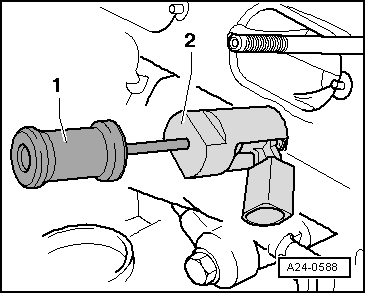

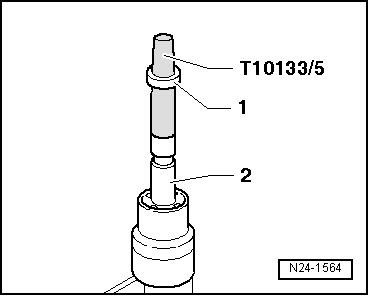

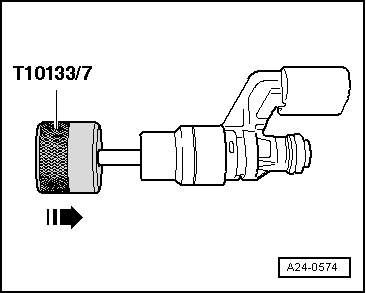

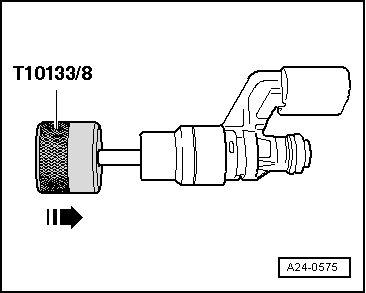

| Carefully remove old teflon ring using suitable tools (e.g. cut open ring using razor blade, or prise open ring with small screwdriver and then pull off forwards). It is important to ensure that the groove and the continuous ridge in the bottom of the groove are not damaged. |

Note | The injector must be renewed if the groove is damaged. |

| –

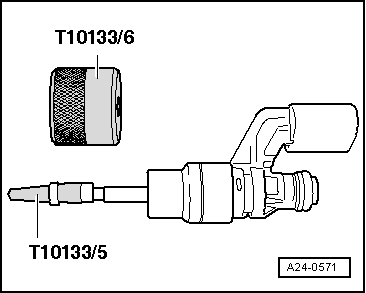

| Before new teflon ring is fitted, any combustion residue must be removed from ring groove and injector stem using a clean cloth. |

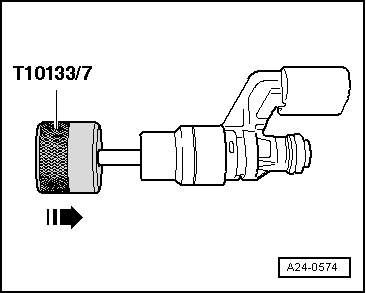

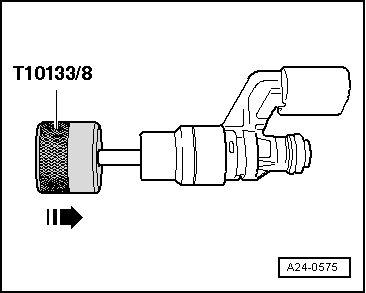

Note | The illustration shows an injector with “offset connector”. This can be ignored since it is not relevant when replacing the combustion chamber ring seal. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note