A4 Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

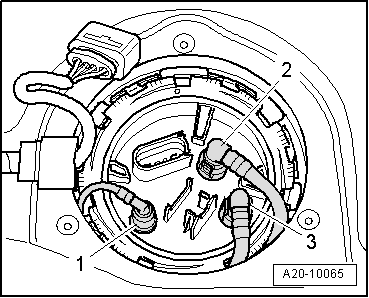

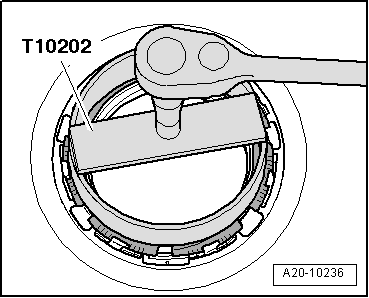

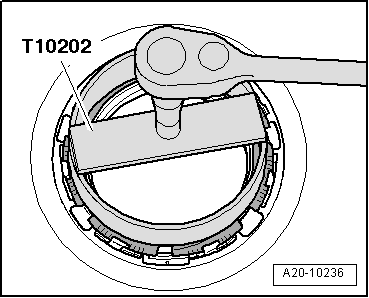

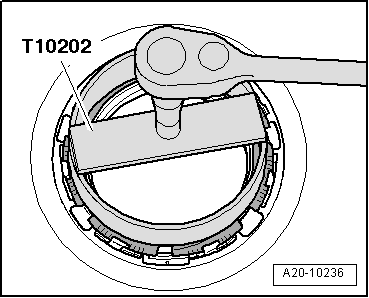

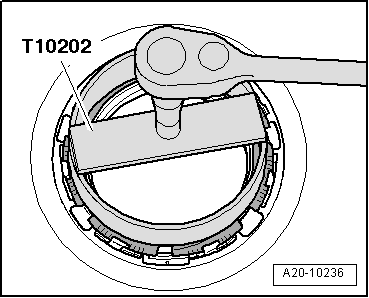

| Component | Nm |

| Locking ring for fuel delivery unit or flange of fuel gauge sender 2 -G169- | 145 |

WARNING

WARNING Caution

Caution