A4 Mk2

|

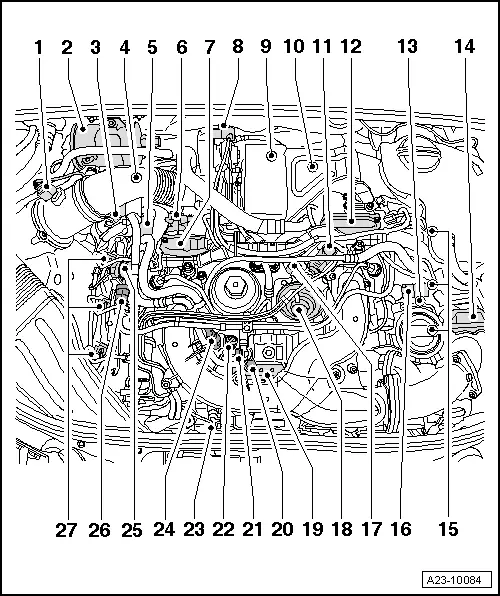

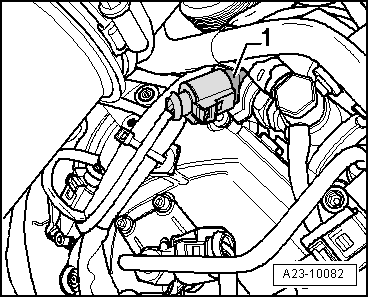

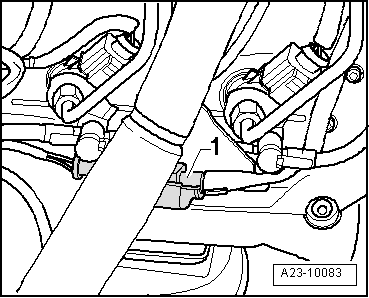

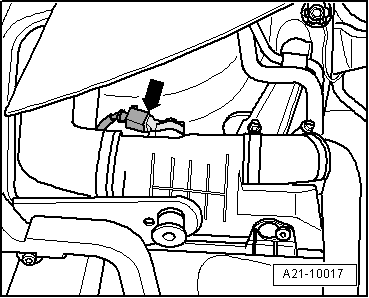

| 1 - | Air mass meter -G70- |

| q | → Fig. |

| q | Removing and installing → Chapter |

| 2 - | Fuel filter |

| q | Renewing → Rep. gr.20 |

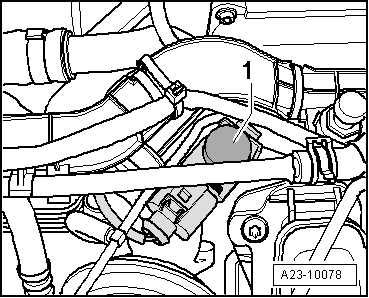

| 3 - | Hall sender -G40- (camshaft position sensor) |

| q | Fitting location → Fig. |

| 4 - | Coolant temperature sender -G62- |

| q | Removing and installing → Rep. gr.19 |

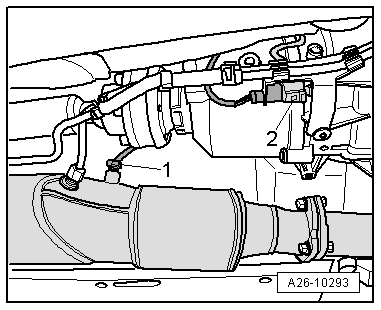

| 5 - | Fuel pressure regulating valve -N276- |

| q | Fitting location → Fig. „„Fuel pressure regulating valve -N276--1-““ |

| q | Removing and installing → Chapter |

| 6 - | Connector for exhaust gas temperature sender 1 -G235- |

| 7 - | Intake manifold flap motor -V157- |

| q | Cylinder bank 1 |

| q | Removing and installing → Chapter |

| q | Intake manifold - exploded view → Chapter |

| 8 - | Control unit for turbocharger 1 -J724- |

| q | Removing and installing → Rep. gr.21 |

| 9 - | Exhaust gas temperature sender 1 -G235- |

| q | On turbocharger |

| q | Removing and installing → Rep. gr.26 |

| 10 - | Lambda probe -G39- with Lambda probe heater -Z19- |

| q | Removing and installing → Chapter |

| 11 - | Exhaust gas recirculation cooler change-over valve -N345- |

| q | Fitting location → Fig. |

| q | Overview of exhaust gas recirculation system → Rep. gr.26 |

| 12 - | Intake manifold flap 2 motor -V275- |

| q | Cylinder bank 2 |

| q | Removing and installing → Chapter |

| q | Intake manifold - exploded view → Chapter |

| 13 - | Connector for Lambda probe -G39- |

| q | Fitting location → Fig. |

| 14 - | Throttle valve module -J338- |

| 15 - | Injectors (piezo injectors) |

| q | Cylinder bank 2 |

| q | Removing and installing → Chapter |

| 16 - | Fuel pressure sender -G247- |

| q | Removing and installing → Chapter |

| 17 - | Vacuum unit |

| q | For change-over flap for exhaust gas recirculation cooler |

| 18 - | Mechanical exhaust gas recirculation valve |

| q | Overview of exhaust gas recirculation system → Rep. gr.26 |

| q | Removing and installing → Rep. gr.26 |

| 19 - | High-pressure fuel pump |

| q | With gear-type fuel system pressurisation pump |

| q | With fuel metering valve -N290- |

| q | High-pressure pump generates fuel pressure up to 1600 bar |

| q | Gear-type fuel system pressurisation pump generates fuel pressure between 4 and 5 bar |

| q | Exploded view: vehicles up to 09.2005 → Chapter; vehicles from 09.2005 onwards → Chapter |

| q | Removing and installing: vehicles up to 09.2005 → Chapter; vehicles from 09.2005 onwards → Chapter |

| 20 - | Fuel supply line connection |

| 21 - | Fuel return line connection |

| 22 - | Fuel metering valve -N290- |

| q | Do not unscrew |

| q | Screwed directly into high-pressure fuel pump |

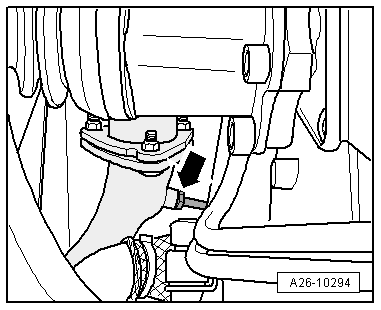

| 23 - | Exhaust gas recirculation valve -N18- |

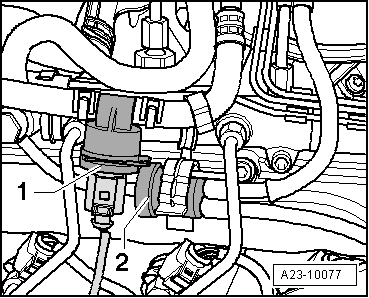

| q | Fitting location → Fig. |

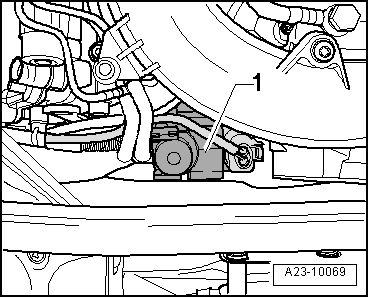

| 24 - | Oil pressure switch -F1- |

| q | → Fig. |

| q | Removing, installing and testing → Rep. gr.17 |

| 25 - | Fuel temperature sender -G81- |

| q | Fitting location → Fig. |

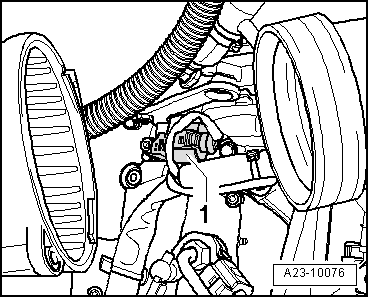

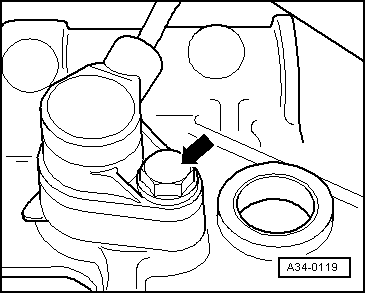

| 26 - | Pressure retention valve |

| q | → Fig. |

| q | In return lines from cylinder banks 1 and 2 |

| q | The pressure retention valve maintains a residual pressure of approx. 10 bar in the return lines. |

| q | This residual pressure is required for the control function of the piezo injectors. |

| q | The pressure retention valve may only be renewed together with the fuel return lines. |

| q | After replacement, engine must be run at idling speed for approx. 2 minutes to bleed fuel system |

| q | Checking pressure retention valve → Chapter |

| 27 - | Injectors (piezo injectors) |

| q | Cylinder bank 1 |

| q | Removing and installing → Chapter |

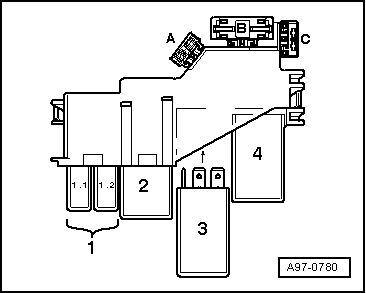

| A - | Electronics box in plenum chamber |

| q | Engine control unit -J623- with altitude sender |

| q | Removing and installing → Chapter |

| q | Fuel pump relay -J17- → Fig. |

| q | Starter inhibitor relay -J207- → Fig. |

| q | Terminal 30 voltage supply relay -J317- → Fig. |

| q | Automatic glow period control unit -J179- → Fig. |

| B - | Brake light switch -F- and brake pedal switch -F47- |

| q | In footwell on brake pedal |

| C - | Accelerator position sender -G79- and accelerator position sender 2 -G185- |

| q | In footwell on accelerator pedal |

| q | On vehicles with automatic gearbox the function of the kick-down switch must be re-adapted if this part is renewed. |

| q | Refer to Guided Fault Finding or → Rep. gr.20 for adapting kick-down function |

| D - | Charge pressure sender -G31- |

| q | With intake air temperature sender -G42- |

| q | In charge air cooler (left-side) → Fig. |

| q | Removing and installing → Rep. gr.21 |

| E - | Starter motor relay -J53- and starter motor relay 2 -J695- |

| q | For fitting location refer to → Current flow diagrams, Electrical fault finding and Fitting locations |

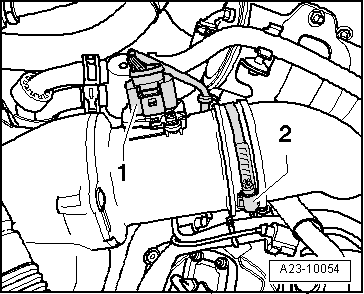

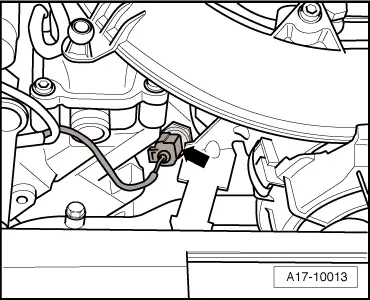

| F - | Engine speed sender -G28- |

| q | Fitting location → Fig. |

| G - | Low heat output relay -J359- and high heat output relay -J360- |

| q | Fitting location in 3-position relay carrier → Current flow diagrams, Electrical fault finding and Fitting locations |

| H - | Air filter bypass flap valve -N275- |

| q | These components (bypass flap with air filter bypass flap valve -N275-) are not installed on certain equipment versions or on vehicles for certain export markets |

| q | If fitted, the bypass flap is located in the air cleaner housing and the air cleaner bypass flap valve -N275- is located on the outside of the air cleaner housing |

| I - | Exhaust gas temperature sender 2 for cylinder bank 1 -G448- |

| q | Only fitted on vehicles with particulate filter |

| q | Located downstream of starter catalytic converter |

| q | For fitting location refer to → Fig. |

| q | Removing and installing → Rep. gr.26 |

| J - | Temperature sender before particulate filter -G506- |

| q | Only fitted on vehicles with particulate filter |

| q | Located between main catalytic converter and particulate filter |

| q | For fitting location refer to → Fig. |

| q | Removing and installing → Rep. gr.26 |

| K - | Exhaust gas pressure sensor 1 -G450- |

| q | Only fitted on vehicles with particulate filter |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Chapter |

| L - | Particulate filter |

| q | Fitted on vehicle underbody |

| q | Combined as one component with main catalytic converter (located upstream) |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Rep. gr.26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|