A4 Mk2

|

| Grease | of which in: | ||

| Outer joint | Total quantity | Joint | Boot |

| Ø mm | [g] | [g] | [g] |

| 100 | 120 | 80 | 40 |

| 88 | 90 | 50 | 40 |

| Inner joint | |||

| 130 | 70 | 60 | |

|

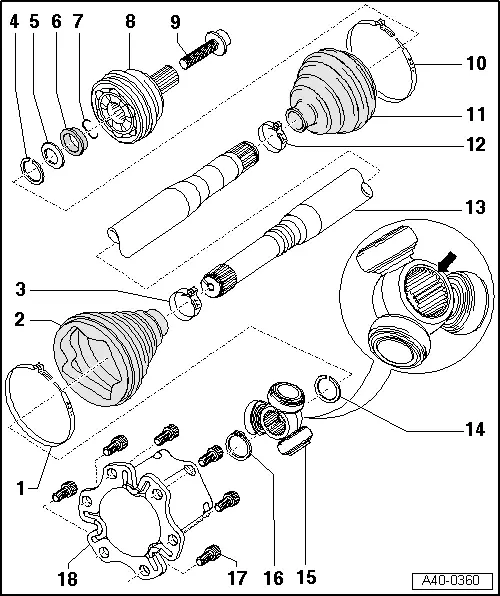

| 1 - | Hose clip |

| q | Always renew |

| q | Different types of hose clip can be fitted, depending on version → Parts catalogue |

| q | Can also be fitted using pliers 3340 |

| 2 - | Boot for triple roller joint |

| q | Boot must rest in groove and on contour of joint body |

| 3 - | Hose clip |

| q | Always renew |

| 4 - | Circlip |

| q | Not fitted on all versions |

| q | For correct version refer to → Parts catalogue |

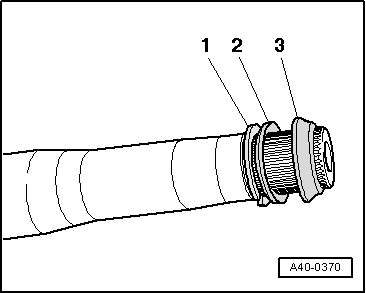

| 5 - | Dished spring |

| q | Not fitted on all versions |

| q | Installation position → Fig. |

| q | For correct version refer to → Parts catalogue |

| 6 - | Spacer ring (plastic) |

| q | Not fitted on all versions |

| q | Installation position → Fig. |

| q | For correct version refer to → Parts catalogue |

| 7 - | Circlip |

| q | Always renew |

| q | Fit into annular groove on shaft before installing (no longer visible once joint is installed) |

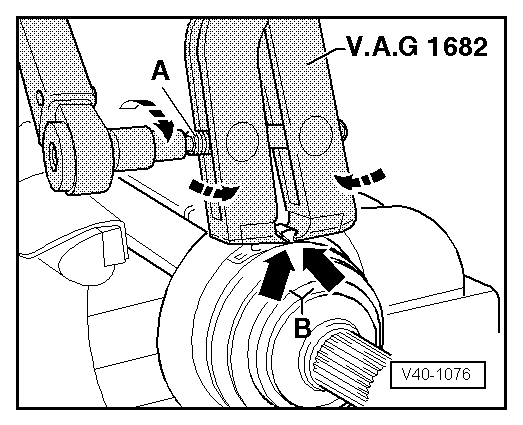

| 8 - | Outer constant velocity joint |

| q | Renew only as complete unit |

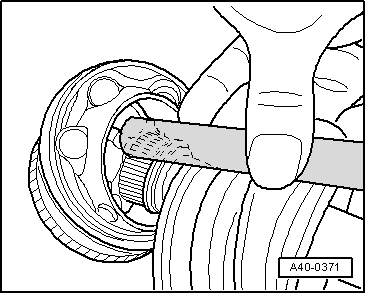

| q | Pressing off → Fig. |

| q | Installing: |

| q | Drive joint onto shaft with plastic hammer until circlip engages |

| q | Greasing → Chapter |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 9 - | Bolt |

| q | Always renew if removed |

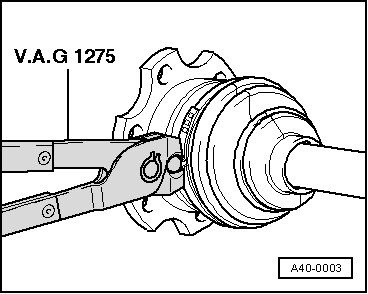

| q | Loosening → Anchor |

| q | Tightening → Anchor |

| q | Tightening torque → Anchor |

| 10 - | Hose clip |

| q | Different versions for rubber or Hytrel boot → Parts catalogue |

| q | Renew |

| 11 - | Boot for outer constant velocity joint |

| q | Check for splits and chafing |

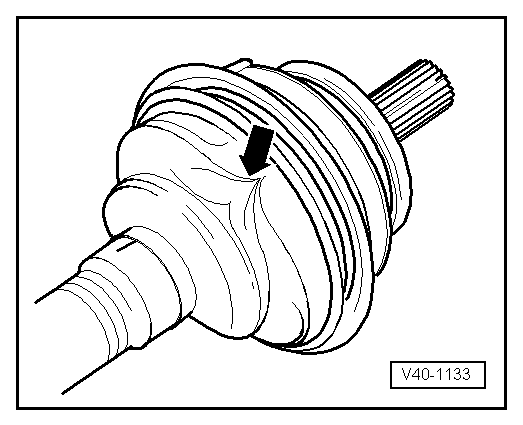

| q | Briefly lift boot to equalise pressure before tightening hose clips → Fig. |

| q | Different versions (rubber or Hytrel) → Parts catalogue |

| 12 - | Hose clip |

| q | Renew |

| 13 - | Drive shaft |

| q | Different versions available → Parts catalogue |

| 14 - | Circlip |

| q | For correct version refer to → Parts catalogue |

| 15 - | Triple roller spider |

| q | Chamfer -arrow- faces towards drive shaft splines |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting triple roller spider onto drive shaft. |

| 16 - | Circlip |

| q | Renew |

| q | Insert in groove on shaft |

| 17 - | Multi-point socket head bolt |

| q | Tightening torques → Item |

| q | For correct version refer to → Parts catalogue |

| 18 - | Joint body |

|

|

|

|

|

|

|

|

|