A4 Mk2

| Dismantling and assembling triple roller joint AAR 2900 |

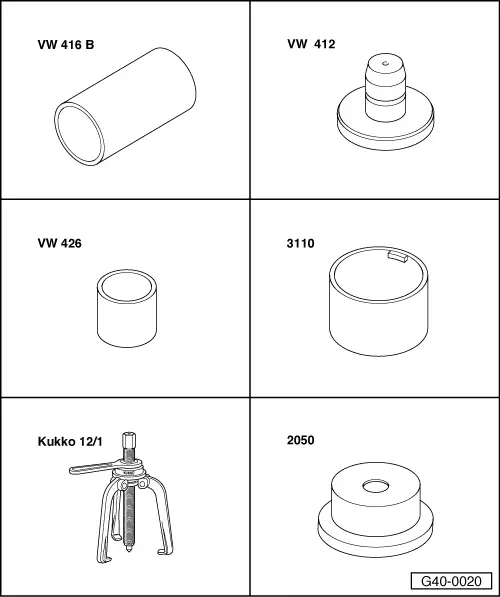

| Special tools and workshop equipment required |

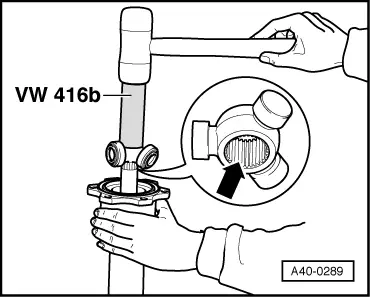

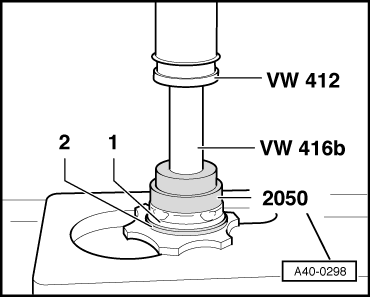

| t | Tube -VW 416 B- |

| t | Press tool -VW 412- |

| t | Tube -VW 426- |

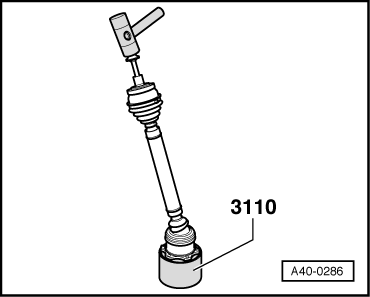

| t | Tube -3110- |

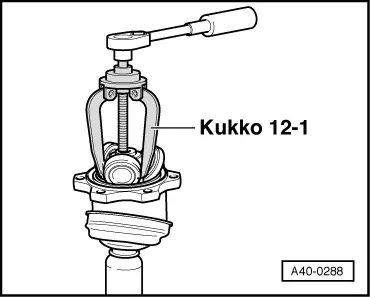

| t | Puller -Kukko 12/1- |

| t | Thrust piece -2050- |

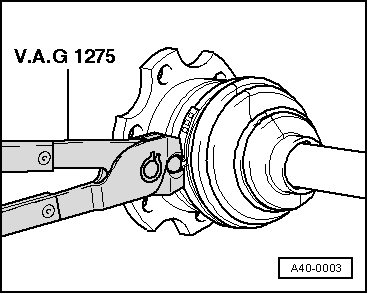

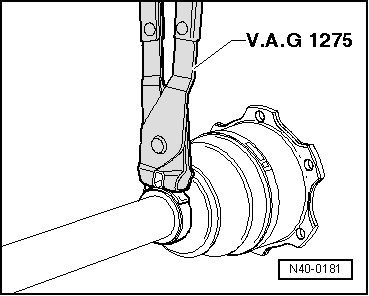

| t | Pliers -V.A.G 1275- |

| t | Circlip pliers -VW 161 A- |

| t | Spindle -3207- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|