A4 Mk2

|

|

|

|

|

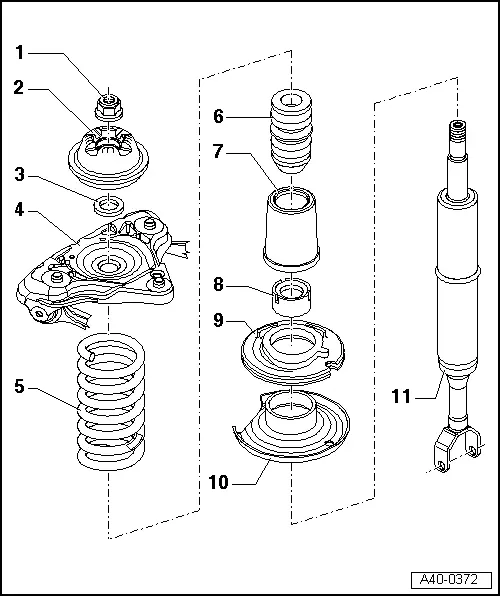

| Exploded view |

| 1 - | Flange nut |

| q | 50 Nm |

| q | Always renew |

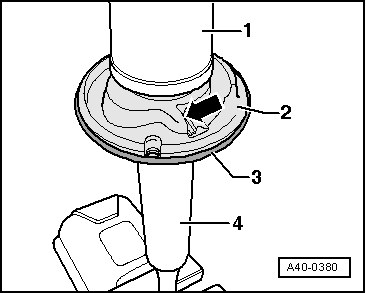

| 2 - | Shock absorber mounting |

| 3 - | Washer |

| 4 - | Mounting bracket |

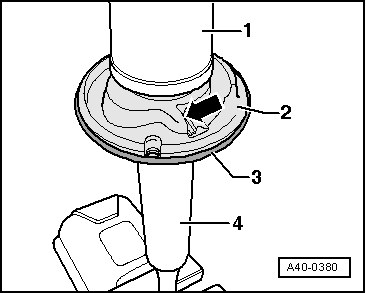

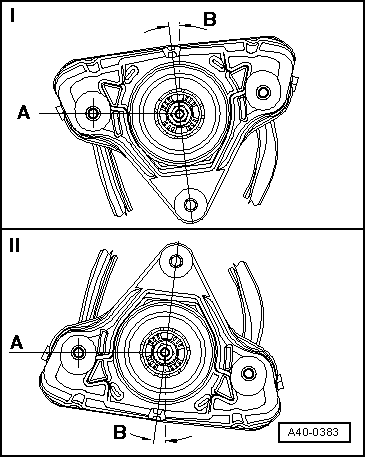

| q | Installation position → Anchor |

| 5 - | Coil spring |

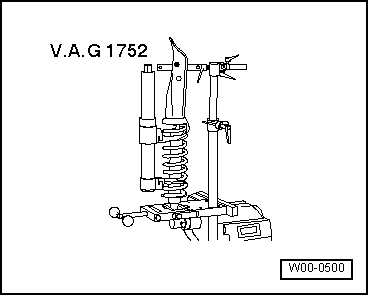

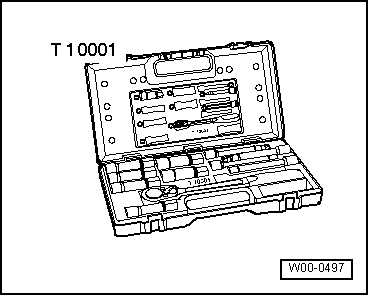

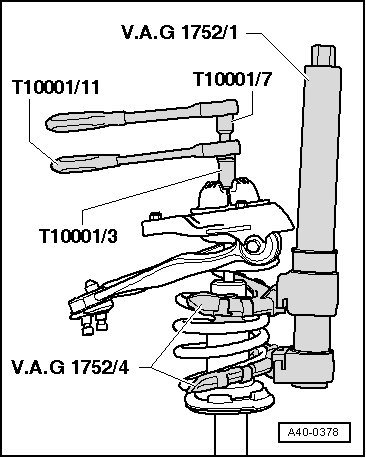

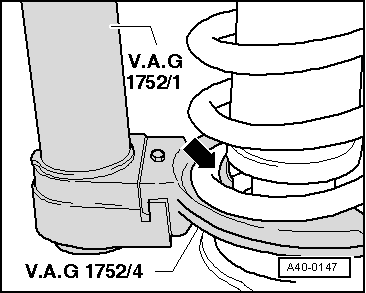

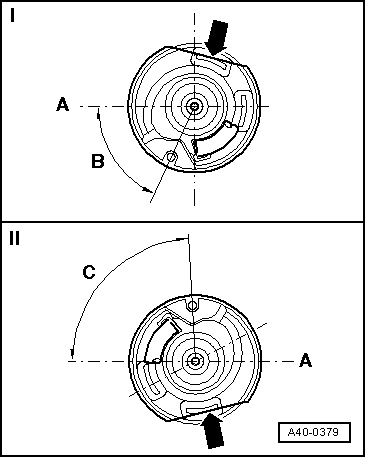

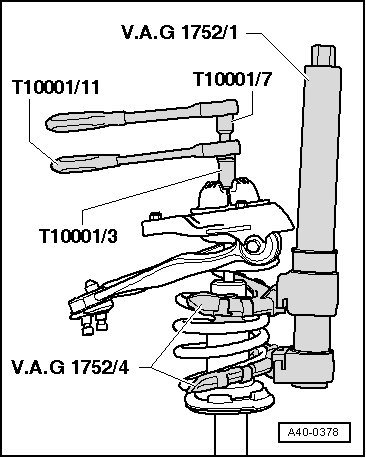

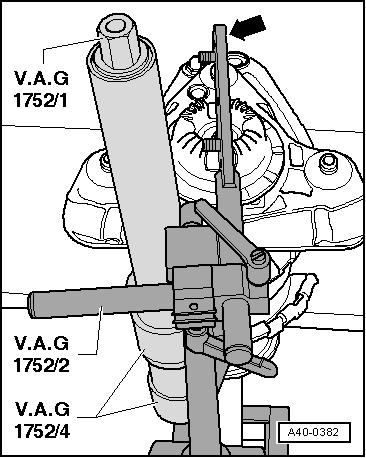

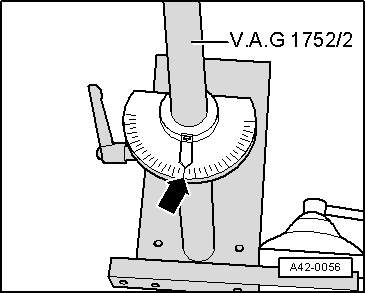

| q | Removing → Fig. and → Fig. |

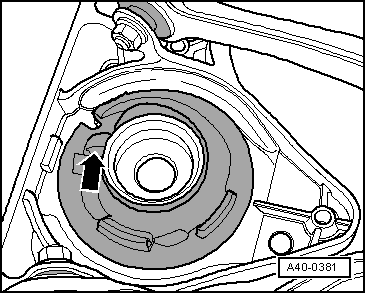

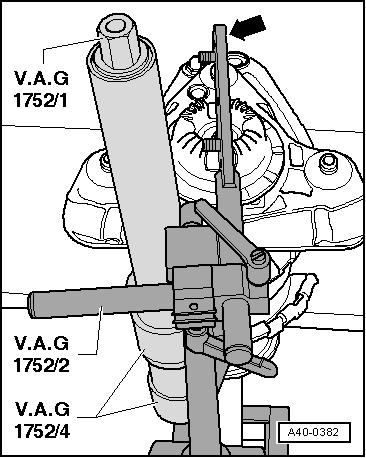

| q | Installing → Fig. |

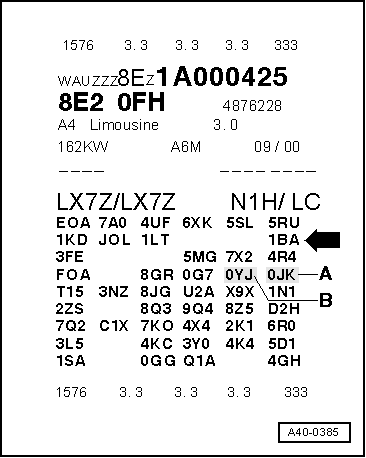

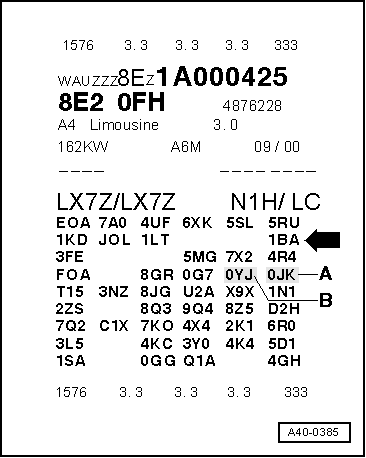

| q | Note different running gear versions; see vehicle data sticker → Anchor |

| q | For correct version refer to → Parts catalogue |

| 6 - | Auxiliary spring |

| 7 - | Protective sleeve |

| 8 - | Protective cap |

| 9 - | Bottom spring seat |

| 10 - | Bottom spring plate |

| q | Installation position → Fig. |

| 11 - | Shock absorber |

| q | Renewing → Fig. |

| q | Note different running gear versions; see vehicle data sticker → Anchor |

| q | Defective shock absorbers must always be degassed and drained before disposal → Chapter |

| q | For correct version refer to → Parts catalogue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|