Caution | Risk of damage to coil connector for airbag. |

| t

| Front wheels must be in straight-ahead position when steering column is detached from steering box. |

| t

| Do not change position of steering wheel or steering box after this step (if necessary, fix steering wheel in position with adhesive tape). |

|

| –

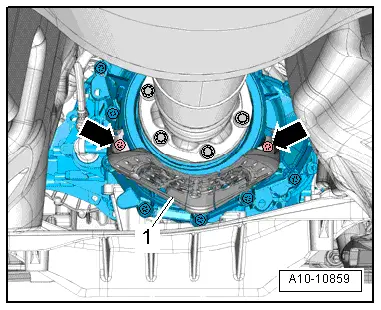

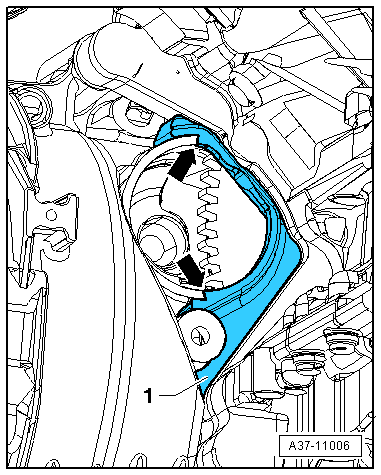

| Move steering wheel as far as possible downwards and to the rear, making use of the full range of the steering column adjuster. |

| –

| Turn steering wheel to centre position (wheels in straight-ahead position) and lock. |

| –

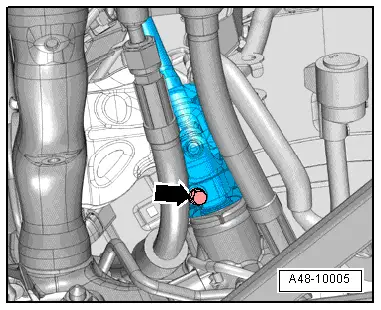

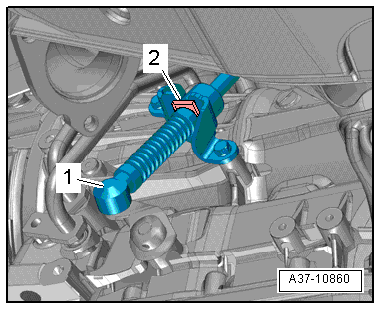

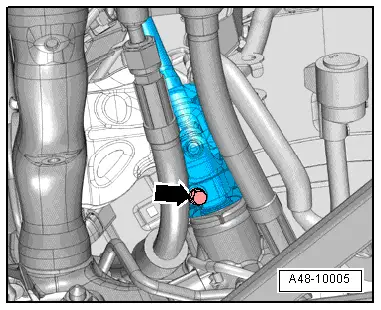

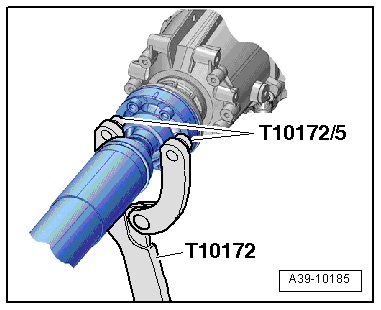

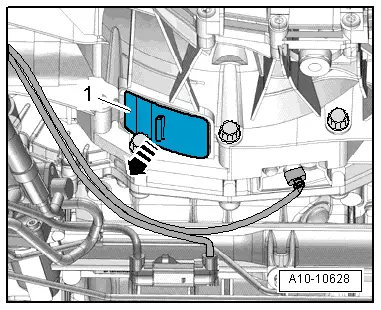

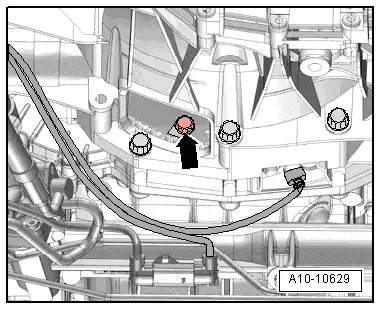

| Press steering column off steering box and push all the way up. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution