A4 Mk3

| Removing gearbox - vehicles with 4.2 ltr. FSI engine |

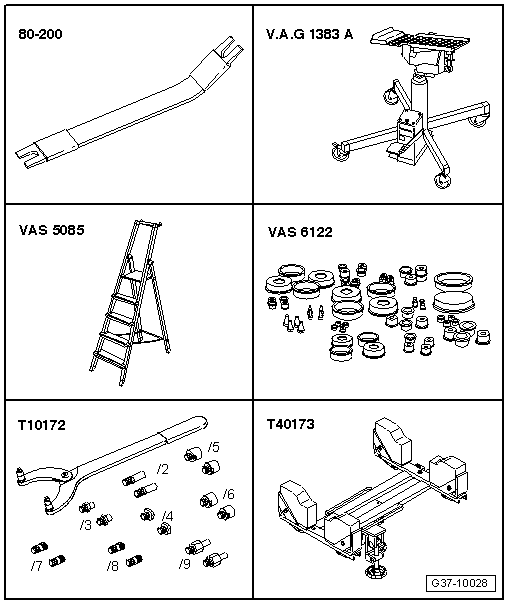

| Special tools and workshop equipment required |

| t | Removal lever -80 - 200- |

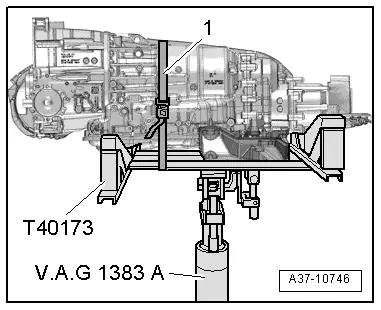

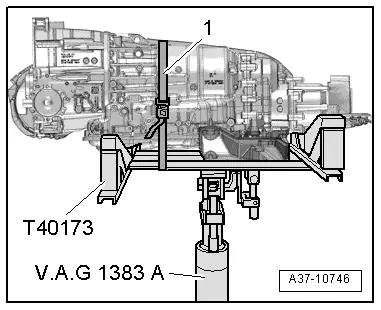

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

| t | Engine bung set -VAS 6122- |

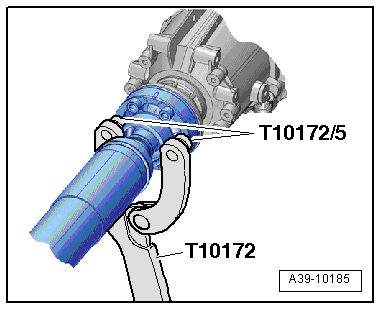

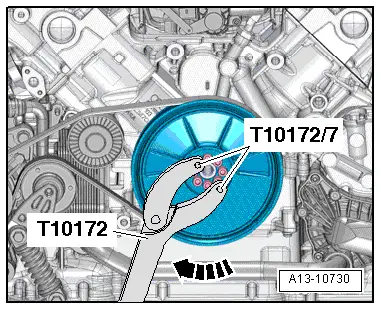

| t | Counter-hold tool -T10172- with -T10172/5- and -T10172/7- |

| t | Gearbox support -T40173- |

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

|

|

Caution

Caution