| –

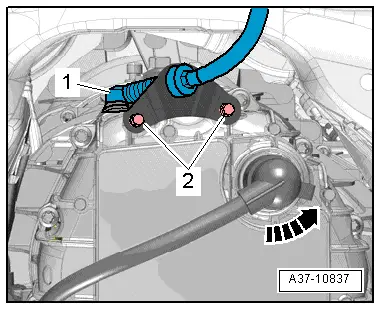

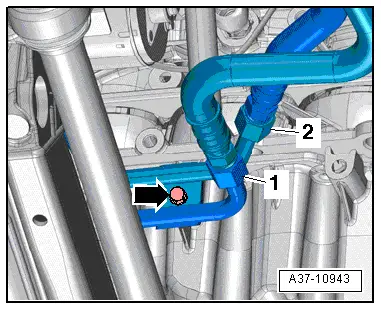

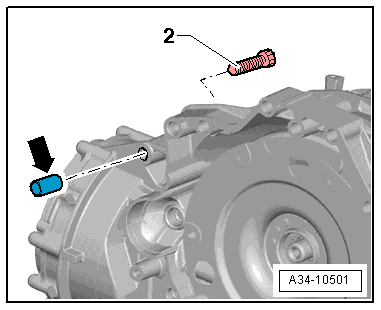

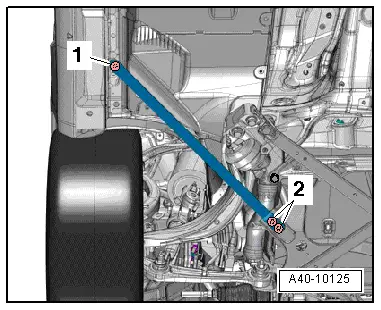

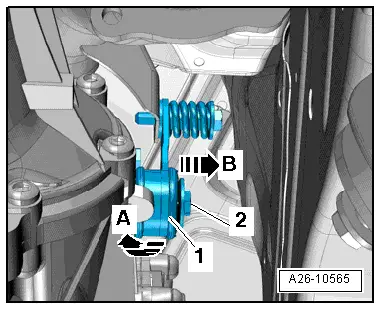

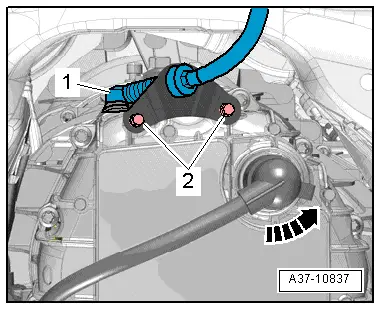

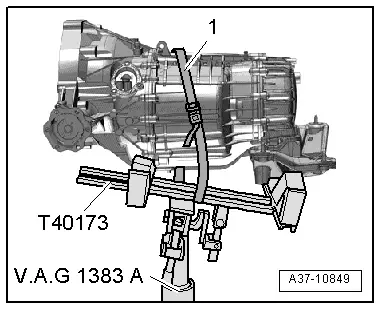

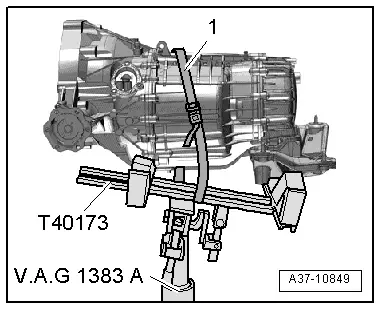

| Use removal lever -80 - 200- to press ball socket -1- on selector lever cable off gearbox selector lever. |

| –

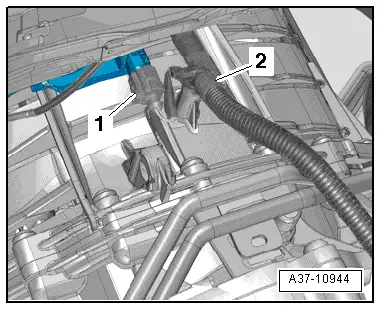

| Remove bolts -2- for cable support bracket. |

| –

| Move selector lever cable clear. |

Note | Do not bend or kink the selector lever cable. |

Caution | The gearbox control unit (mechatronic unit) can be damaged by electrostatic discharge. |

| t

| Before handling the electrical connector, the mechanic must discharge static by briefly touching an earthed metal object, such as vehicle earth, lifting platform or heater radiator, etc. |

| t

| Do not touch contact pins in gearbox connector with bare hands. |

|

| –

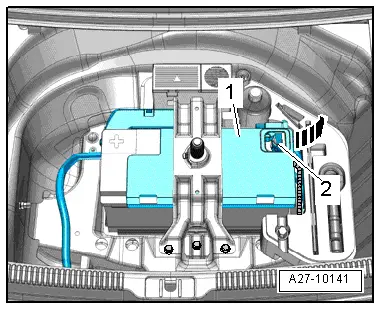

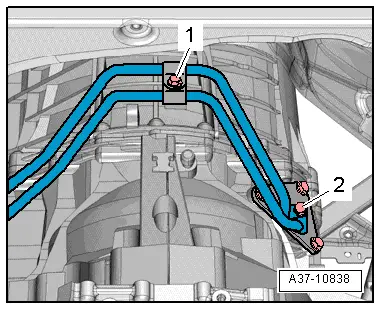

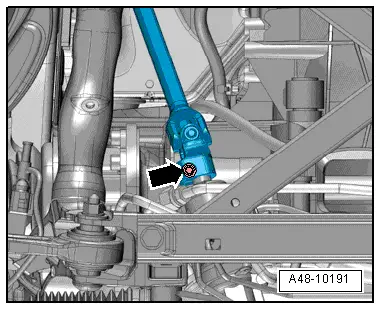

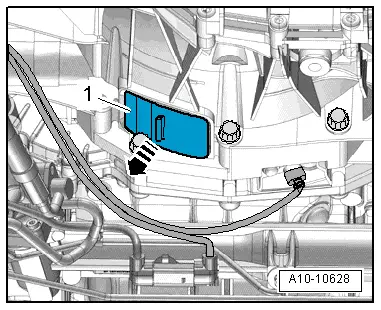

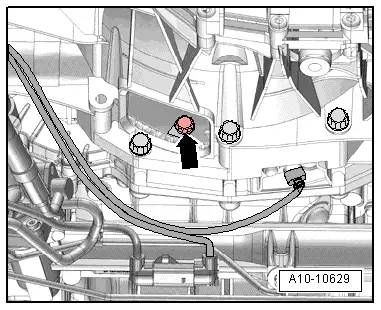

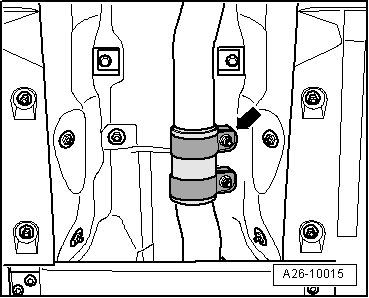

| Turn fastener anti-clockwise -arrow- and unplug electrical connector on gearbox. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution