A4 Mk3

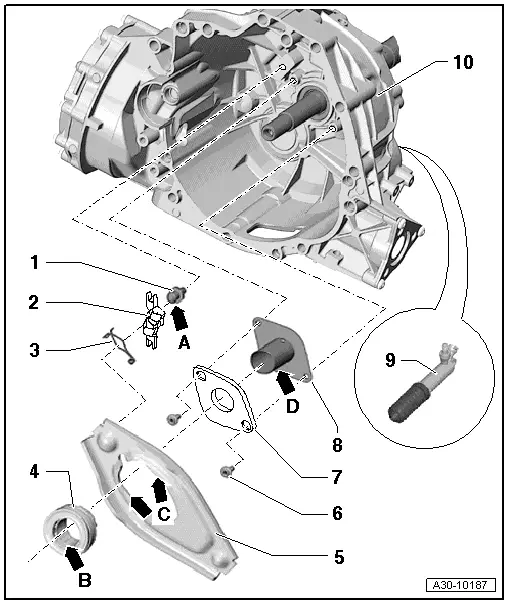

| Exploded view - clutch release mechanism |

| 1 - | Ball-head pin |

| q | 25 Nm |

| q | Coat bearing surface for clutch release lever -arrow A- with grease -G 000 100- |

| 2 - | Intermediate piece |

| q | Renew if damaged |

| 3 - | Retaining spring |

| q | Engage on clutch release lever |

| 4 - | Release bearing |

| q | Different versions |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Do not wash out; wipe clean only |

| q | Renew bearing if noisy |

Note

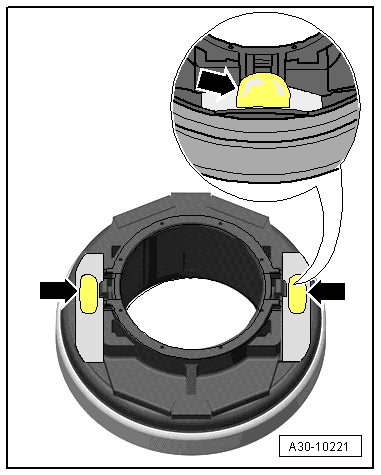

Note| t | Grease bearing surface for clutch release lever thoroughly with lubricating paste -G 000 150- → Fig.. |

| t | Remove any existing grease in bearing surface for guide sleeve -arrow B-: the surface where the release bearing moves on the guide sleeve must be free of grease |

| q | Retainer lugs on release bearing must engage in release lever |

| q | Removing and installing → Chapter |

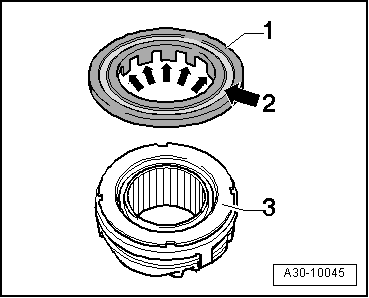

| Release bearing up to 02.2008 |

| l | Inner diameter -arrow B-: 34 mm |

| l | Checking release bearing → Fig. |

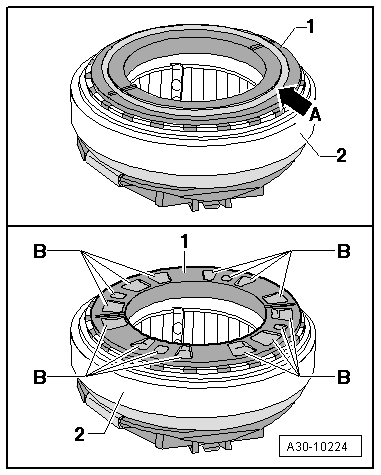

| Clutch release bearing with tumbler ring - from 02.2008 onwards |

| l | Inner diameter -arrow B-: 36 mm |

| l | Checking release bearing with tumbler ring → Fig. |

| 5 - | Clutch release lever |

| q | Different versions |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Remove existing grease from release lever |

| q | Re-grease bearing surface for release bearing -arrows C- with lubricating paste -G 000 150- |

| q | Removing and installing → Chapter |

| 6 - | Bolt |

| q | 8 Nm |

| q | Different bolt length |

| q | For correct version, refer to → Electronic parts catalogue |

| q | 2x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 7 - | Retaining piece |

| q | For guide sleeve |

Note

Note| t | Discontinued as of 02.2008 |

| t | Is also omitted when new guide sleeve is installed → Item |

| t | For correct version, refer to → Electronic parts catalogue |

| 8 - | Guide sleeve |

| q | Different versions |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Remove grease from guide sleeve -arrow D- – clutch release bearing must be fitted free of grease on guide sleeve |

| Guide sleeve up to 02.2008 |

| l | Diameter -arrow D-: 34 mm |

| l | If renewed, install without retaining piece → Item |

| Guide sleeve from 02.2008 onwards |

| l | Fitted on clutch release bearing with tumbler ring → Fig. |

| l | Diameter -arrow D-: 36 mm |

| l | Is installed without retaining piece → Item |

| 9 - | Clutch slave cylinder |

| q | Removing and installing → 6-speed manual gearbox 0B1, front-wheel drive; Rep. gr.30 |

| q | Do not operate clutch pedal after slave cylinder has been removed |

| q | Observe correct sequence when bleeding → 6-speed manual gearbox 0B1, front-wheel drive; Rep. gr.30 |

| q | When installing, push in until the securing bolt can be fitted. |

| 10 - | Gearbox |

|

|

|

|

Caution

Caution