| –

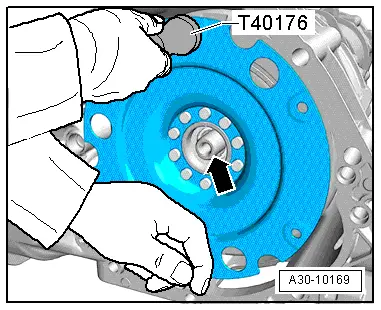

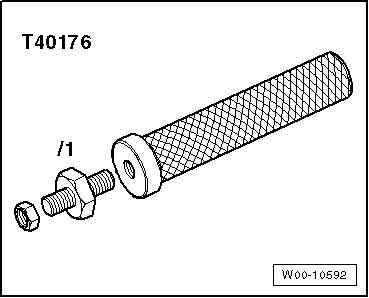

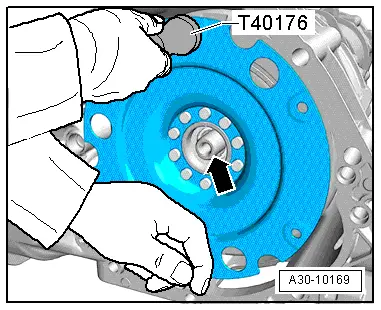

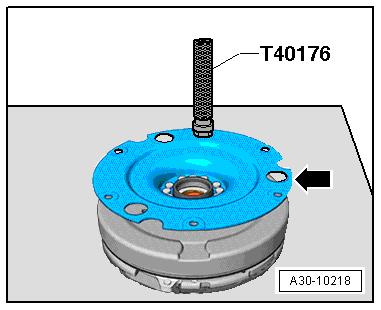

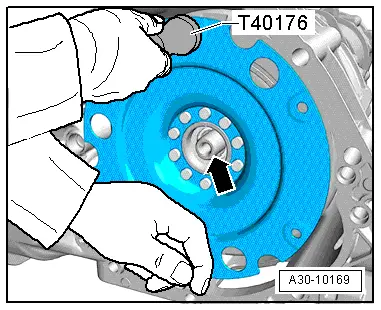

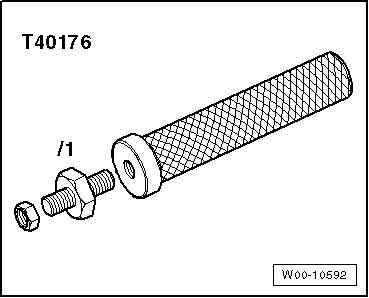

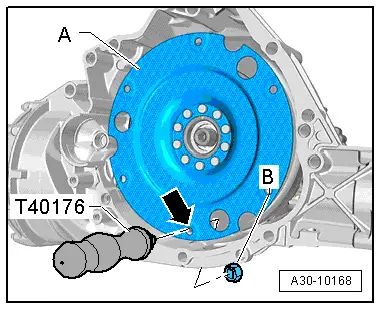

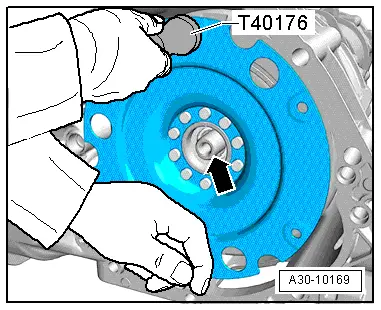

| Turn extractor -T40176- upwards. |

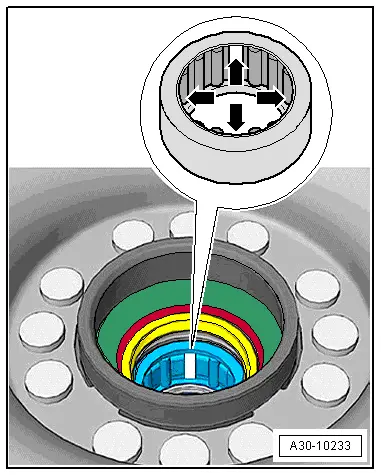

Caution | Risk of damage to oil seals and needle bearing in dual-mass flywheel. |

| t

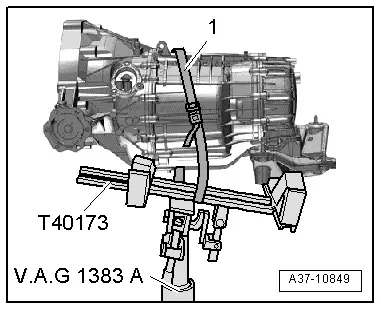

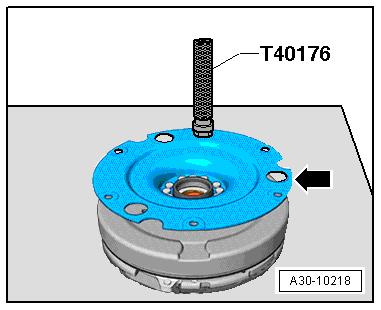

| The clutch module weighs approx. 20 kg. |

| t

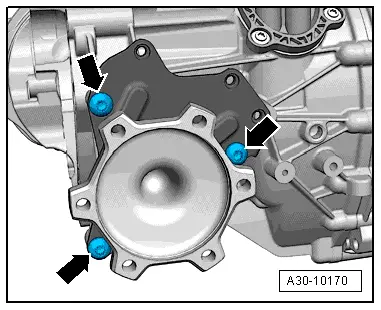

| Keep firm hold of the bottom of the clutch module, as shown in the illustration, to prevent the clutch module from tilting over. |

| t

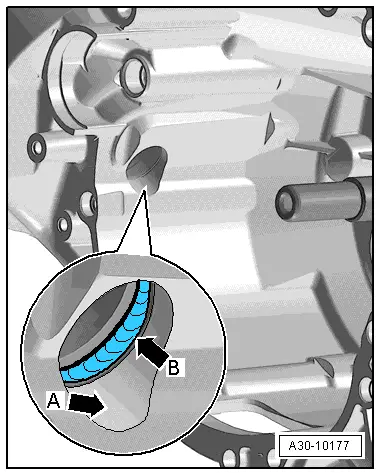

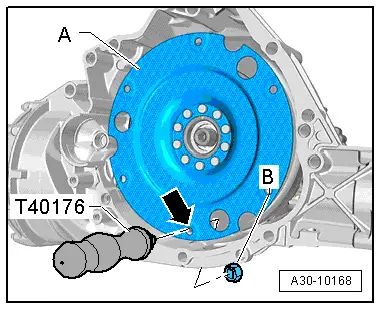

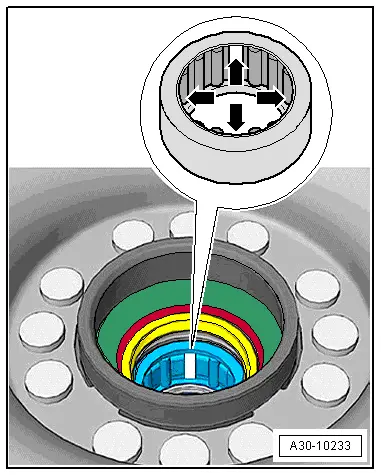

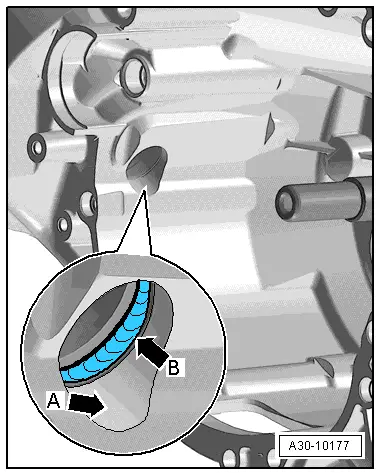

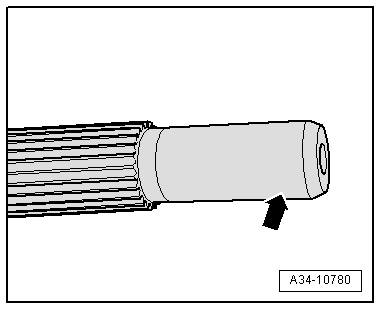

| When removing and installing the clutch module, take care not to damage the oil seals and needle bearing in the dual-mass flywheel -arrow-. |

| t

| Renew oil seals or needle bearing if damaged → Chapter. |

|

| –

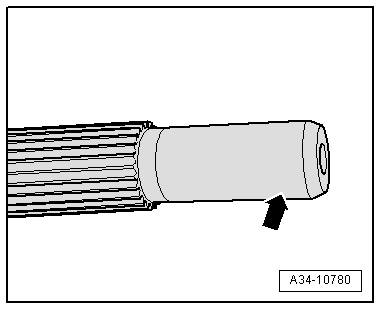

| Pull clutch module off input shaft -arrow-, keeping clutch module straight. |

|

|

|

Note

Note

Note

Note