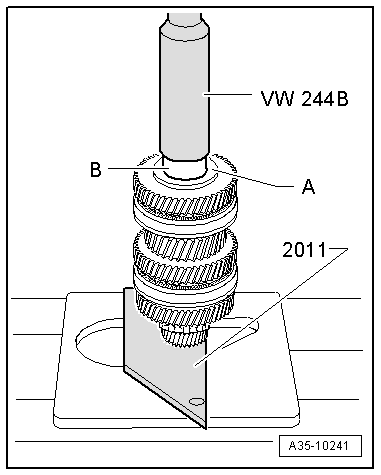

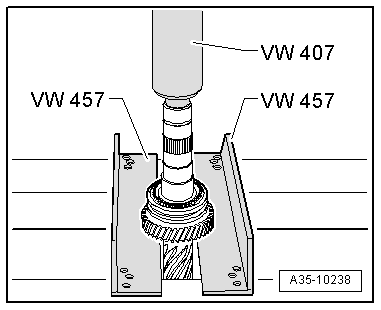

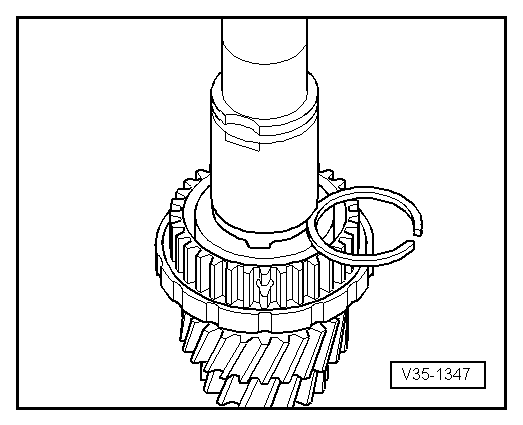

| A - | Splitter 22...115 mm, e.g. -Kukko 17/2- |

Note | t

| The roller bearing will be damaged when it is pressed off and must therefore always be renewed. |

| t

| If the input shaft is being renewed, the roller bearing does not have to be pressed off the shaft. |

| t

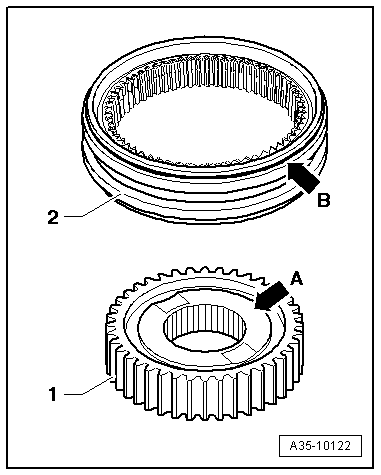

| To press off the roller bearing, you can also break open the cage of the bearing using a screwdriver or similar and then apply the splitter to the inner race. |

| –

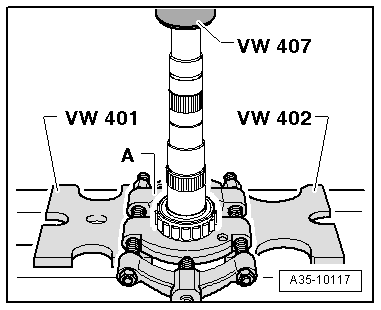

| Clean thread for multi-point socket head bolt in input shaft to remove any remaining locking fluid. |

Note | t

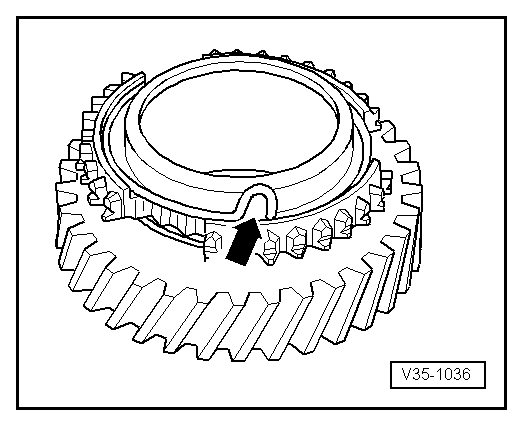

| Lubricate all needle bearings and synchro-rings with gear oil before fitting. |

| t

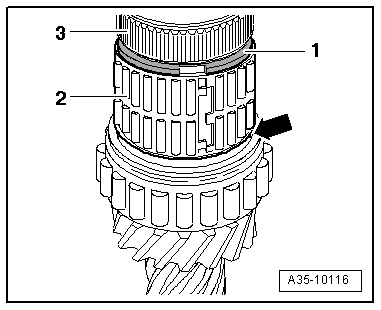

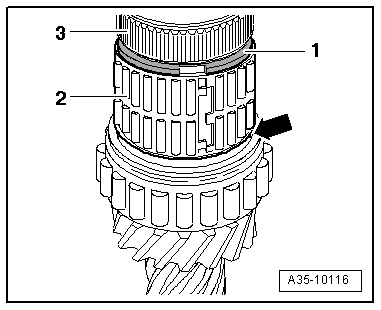

| Note allocation of synchro-rings to locking collars → Chapter. |

| t

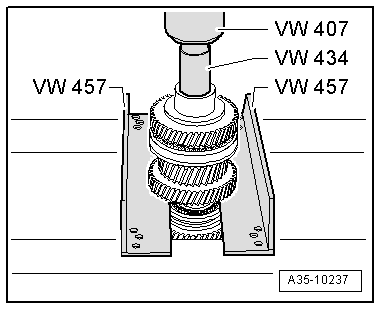

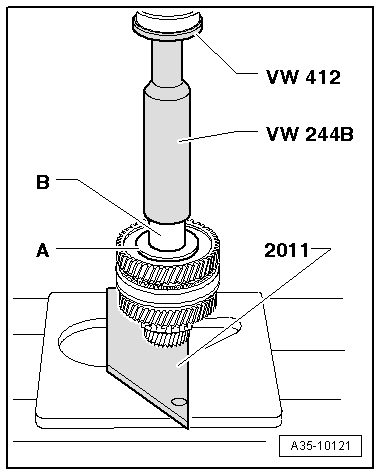

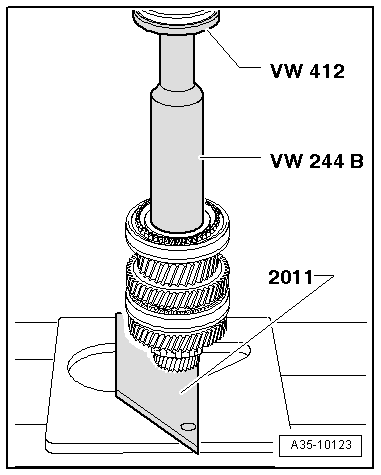

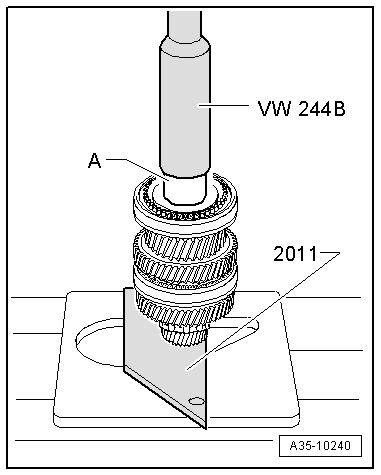

| Using inductive heater -VAS 6414- or similar, heat needle bearing inner races to 130 °C (max.) before pressing on (wear protective gloves). |

| t

| Using inductive heater -VAS 6414- or similar, heat synchro-hub to 100 °C (max.) before pressing on (wear protective gloves). |

| t

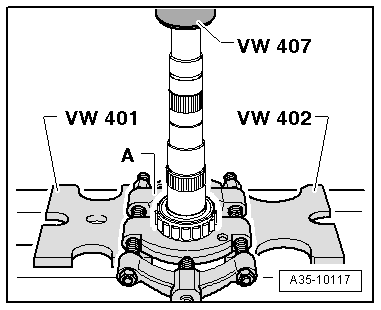

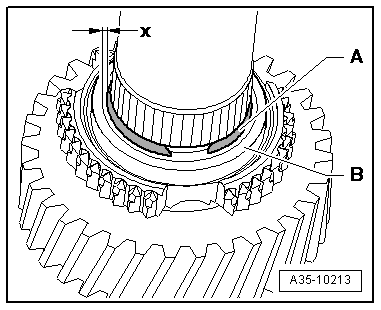

| Always press on roller bearing, needle bearing inner races and synchro-hubs as far as stop to make sure the axial clearance of the selector gears meets the specification. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note