A4 Mk3

| Exploded view - input shaft |

| Detaching input shaft from output shaft and bearing mounting → Chapter |

| Dismantling and assembling input shaft - assembly sequence → Chapter |

Note

Note| t | Refer to technical data when installing new gears or input shaft → 6-speed manual gearbox 0B1, front-wheel drive; Rep. gr.00. |

| t | Lubricate all bearings and synchro-rings on input shaft with gear oil before installing. |

| t | The circlip → Item should only be detached when renewing the roller bearing → Item. |

| t | 3rd to 6th speed selector gears should have an axial play of 0.15 ... 0.50 mm after installing. |

| t | Note allocation of synchro-rings to locking collars → Chapter. |

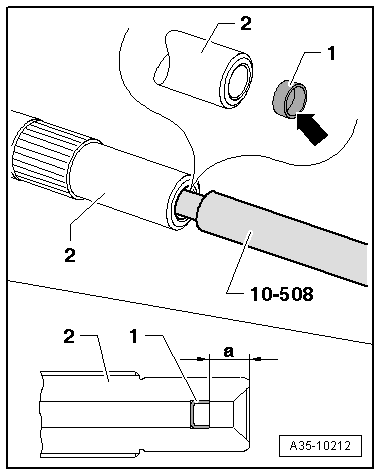

| 1 - | Circlip |

| q | Determining thickness → Fig. |

| 2 - | Gearbox housing |

| 3 - | Ball bearing |

| q | For input shaft |

| q | Removing and installing → Item |

| 4 - | Circlip |

| q | Note installation position → Fig. |

| 5 - | Sealing plug |

| q | For input shaft |

| q | Installing → Fig. |

| 6 - | Input shaft |

| q | With splines for 1st, 2nd and reverse gear |

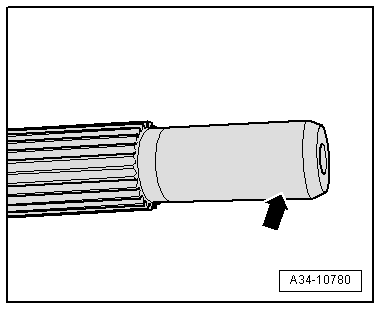

| q | Sealing plug → Item is fitted in bore in vicinity of splines for clutch plate |

| q | Fit sealing plug when renewing input shaft → Fig. |

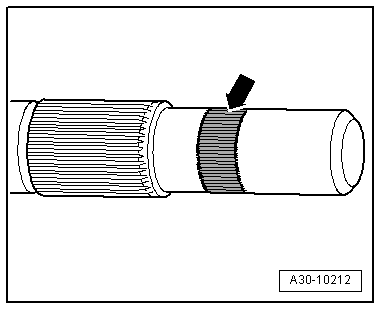

| q | Checking input shaft for wear → Fig. |

| 7 - | Roller bearing |

| q | For input shaft |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| q | Always renew |

| 8 - | Bearing mounting |

| q | Carries bearings for input shaft and output shaft in gearbox cover |

| q | Clean locking fluid out of tapped holes (using thread tap or similar) |

Note

Note| t | The roller bearing outer races on the input shaft and output shaft cannot be renewed separately. |

| t | The roller bearing outer races must not have any radial clearance in the bearing mounting. |

| t | The bearing mounting does not have to be renewed when the roller bearings on the input shaft or output shaft are renewed, e.g. when installing a new input shaft. |

| 9 - | Needle bearing |

| q | For 5th gear |

| q | Installation position → Anchor |

| 10 - | Circlip |

| q | Mark |

| q | Do not interchange with other circlip → Item |

| q | Installation position → Anchor |

| q | Always renew after detaching |

| l | It should not be possible to turn circlip in annular groove on input shaft by hand |

| l | In installation position, circlip must not come into contact with 5th speed selector gear when gear is rotated → Anchor |

| 11 - | 5th speed selector gear |

| l | When rotated, gear must not come into contact with circlip → Item → Anchor |

| 12 - | Synchro-spring |

| q | Fit in 5th speed selector gear → Fig. |

| 13 - | 5th gear synchro-ring |

| q | Checking for wear → Chapter |

| 14 - | Synchro-hub for 5th and 6th gear |

| 15 - | Locking collar for 5th and 6th gear |

| 16 - | Circlip |

| q | Mark |

| q | Do not interchange with other circlip → Item |

| q | Determining thickness → Fig. |

| 17 - | Needle bearing |

| q | For 6th gear |

| 18 - | 6th gear synchro-ring |

| q | Checking for wear → Chapter |

| 19 - | Synchro-spring |

| q | Fit in 6th speed selector gear → Fig. |

| 20 - | 6th speed selector gear |

| 21 - | Thrust washer |

| q | For 3rd speed and 6th speed selector gears |

| 22 - | Needle bearing inner race |

| q | For 3rd gear |

| 23 - | Needle bearing |

| q | For 3rd gear |

| 24 - | 3rd speed selector gear |

| 25 - | Synchro-spring |

| q | Insert in 3rd speed selector gear → Fig. |

| 26 - | 3rd gear synchro-ring |

| q | Checking for wear → Chapter |

| 27 - | Synchro-hub for 3rd and 4th gear |

| q | Installation position: lower inside collar faces 4th gear → Fig. |

| 28 - | Locking collar for 3rd and 4th gear |

| 29 - | Needle bearing inner race |

| q | For 4th gear |

| 30 - | Needle bearing |

| q | For 4th gear |

| 31 - | 4th gear synchro-ring |

| q | Checking for wear → Chapter |

| 32 - | Synchro-spring |

| q | Fit in 4th speed selector gear → Fig. |

| 33 - | 4th speed selector gear |

| 34 - | Thrust washer |

| q | For 4th speed selector gear |

| 35 - | Inner race |

| q | For roller bearing → Item in gearbox cover |

| 36 - | Multi-point socket head bolt |

| q | 200 Nm |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| q | Loosen and tighten with socket for multi-point socket head bolt XZN 12 |

| 37 - | Roller bearing |

| q | Is fitted in gearbox cover |

| q | Removing and installing → Item |

|

|

|

|