A4 Mk3

|

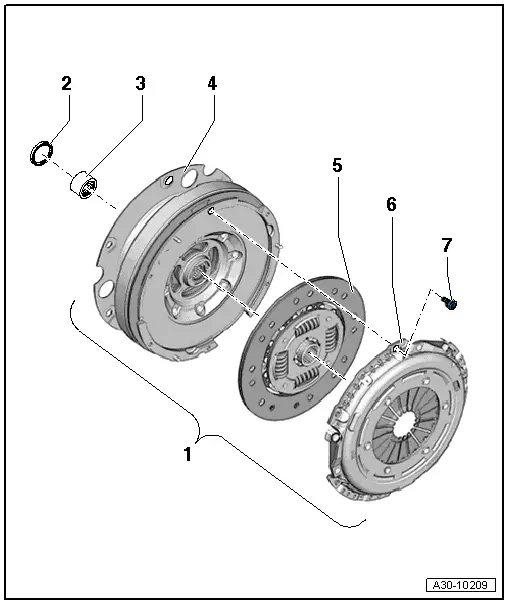

| 1 - | Clutch module |

| q | Removing and installing → Chapter |

| 2 - | Oil seal |

| q | For dual-mass flywheel |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

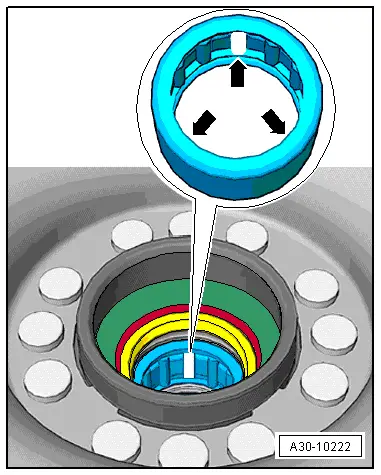

| 3 - | Needle bearing |

| q | For dual-mass flywheel |

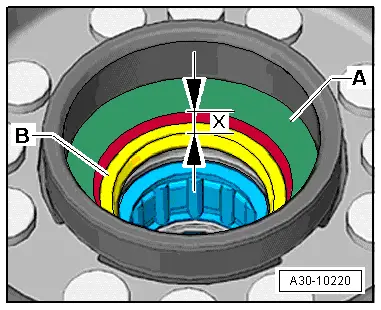

| q | Different versions → Fig. |

| q | Check and renew if necessary → Fig. |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

Note

Note| t | Always renew needle bearing if input shaft is damaged → Anchor |

| t | Depending on the version fitted, the needle bearing may have the full number of rollers, or every 4th roller may be missing. The missing rollers do not mean that the needle bearing is defective. |

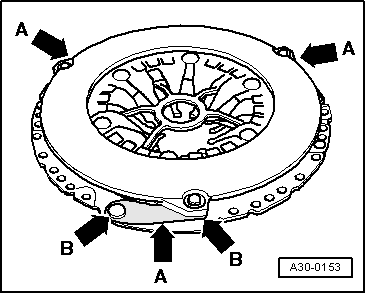

| 4 - | Dual-mass flywheel |

| q | With flange for drive plate |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| q | Removing and installing → Chapter „Removing and installing pressure plate and clutch plate (Sachs version)“ |

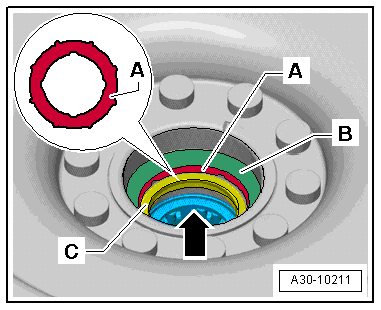

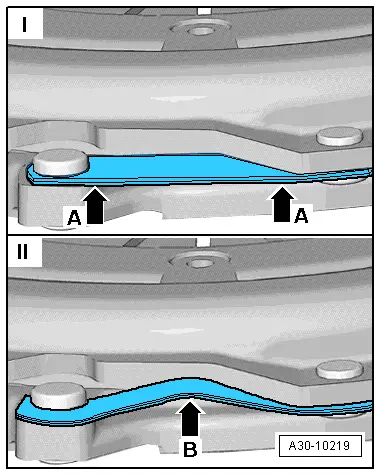

| q | Checking plastic washer in dual-mass flywheel → Fig. |

| q | Measuring degree of wear on plastic washer → Fig. |

| 5 - | Clutch plate |

| q | Removing and installing → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Installation position: marking “Getriebeseite” (gearbox side) faces towards pressure plate |

| q | If fitted, coil springs (damper assembly) face towards pressure plate |

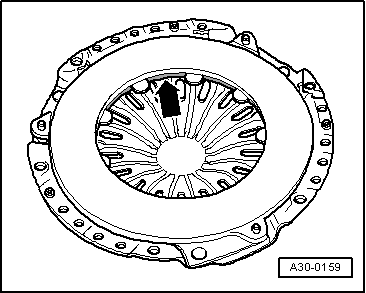

| 6 - | Pressure plate |

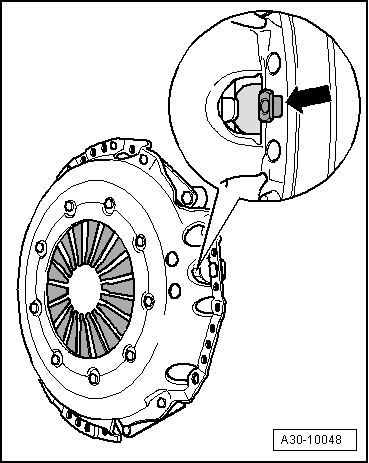

| q | Self-adjusting |

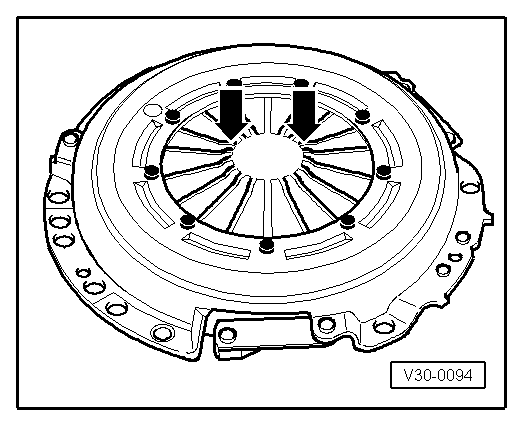

| q | Identification → Fig. |

| q | Pressure plate and clutch plate can only be renewed together |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Removing and installing → Chapter |

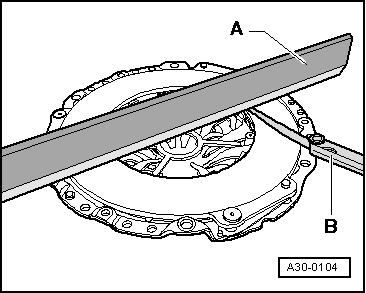

| q | Checking pressure plate for distortion → Fig. |

| q | Checking ends of diaphragm spring → Fig. |

| q | Checking springs and riveting → Fig. |

| q | Checking metal ring → Fig. |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| 7 - | Bolt |

| q | 22 Nm and then turn 90° further |

| q | Always renew |

| q | Secures pressure plate to dual-mass flywheel |

| q | Observe assembly instructions → Chapter for loosening or tightening |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution