A4 Mk3

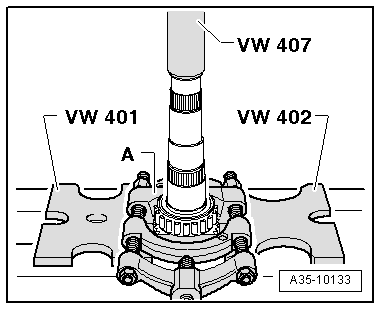

| Dismantling and assembling output shaft |

| Special tools and workshop equipment required |

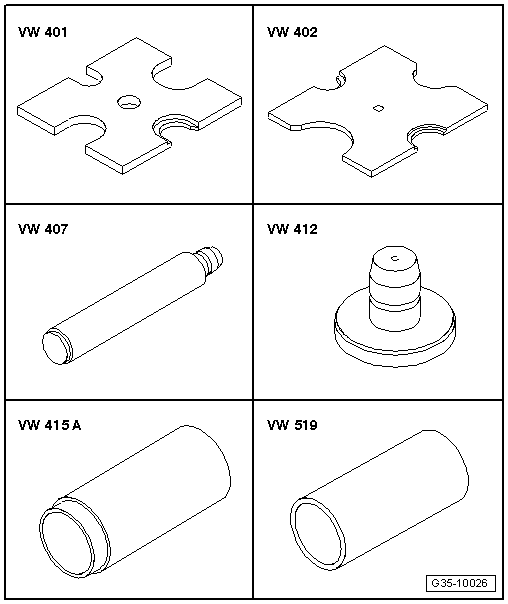

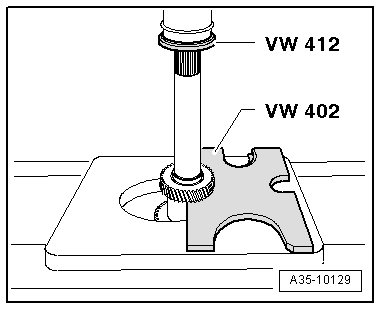

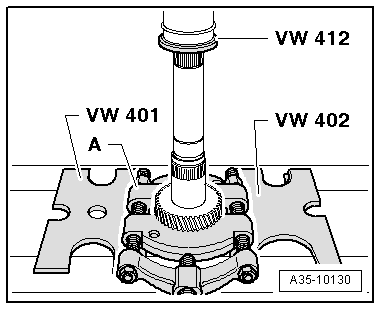

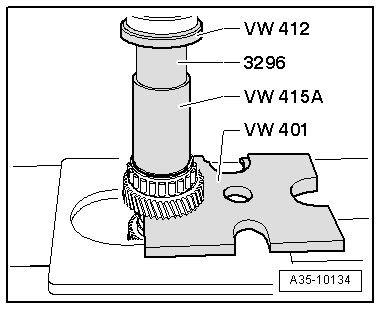

| t | Thrust plate -VW 401- |

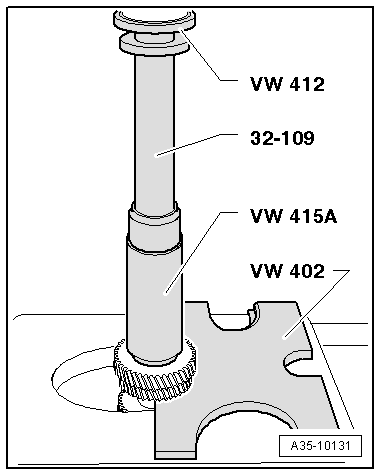

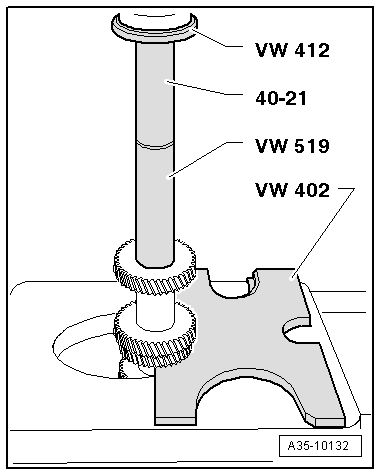

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Tube -VW 519- |

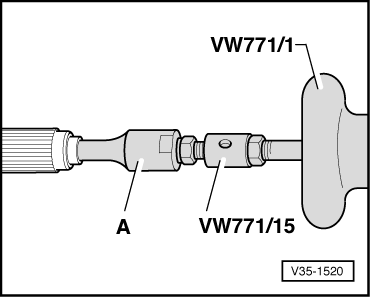

| t | Multi-purpose tool -VW 771- |

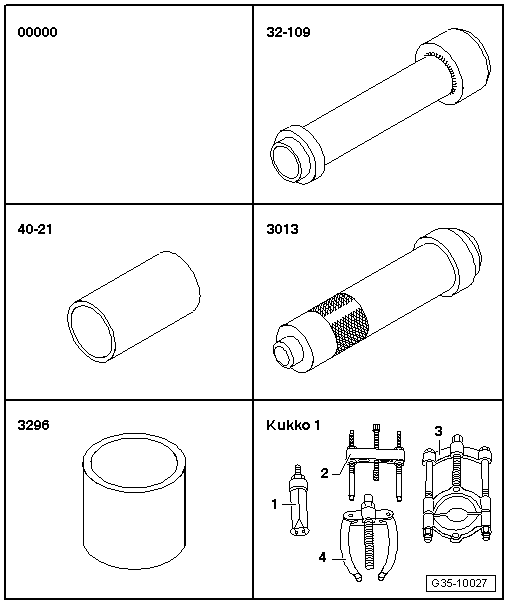

| t | Tube -32 - 109- |

| t | Drift sleeve -40 - 21- |

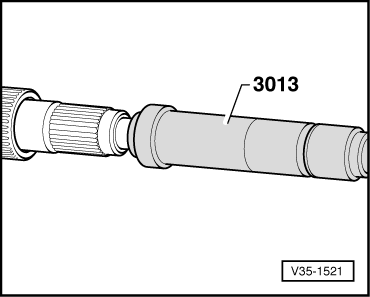

| t | Punch -3013- |

| t | Tube -3296- |

| t | -1-Internal puller -Kukko 21/1- |

| t | -3-Splitter -Kukko 17/2- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

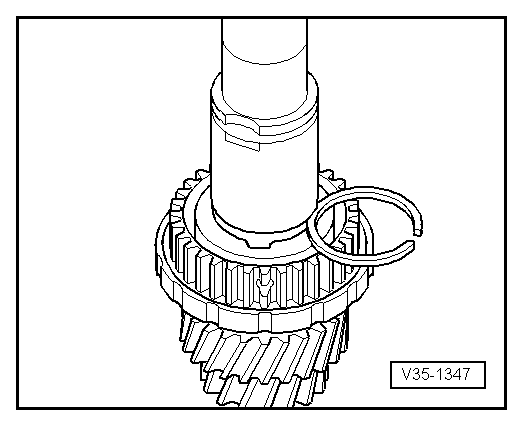

| Circlip thickness (mm) | ||

| 2.35 | 2.41 | 2.47 |

| 2.38 | 2.44 | 2.50 |

|

|

|

|