Note | t

| Refer to general repair instructions → Chapter. |

| t

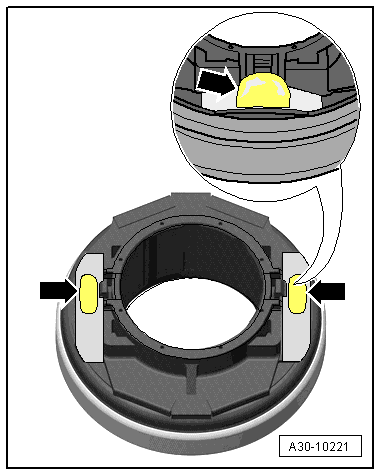

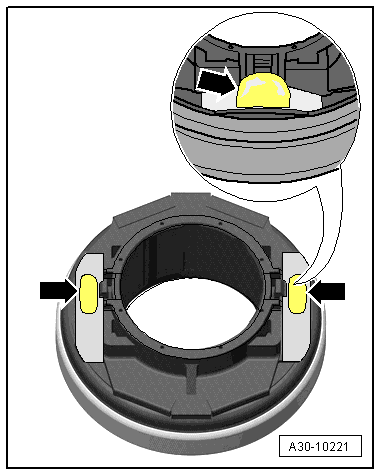

| With the SAC clutch pressure plate (self-adjusting clutch pressure plate), an adjuster ring has to be reset if just the clutch plate is replaced → Chapter. |

| t

| Renew clutch plate and pressure plate if riveted fastening is damaged or loose. |

| t

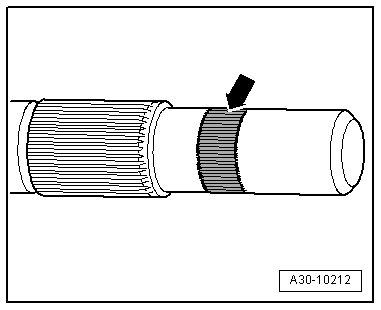

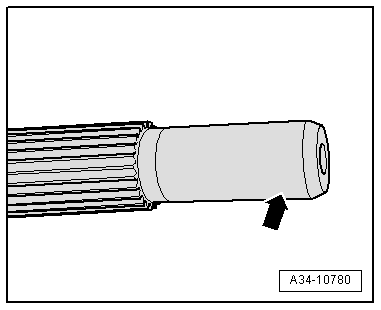

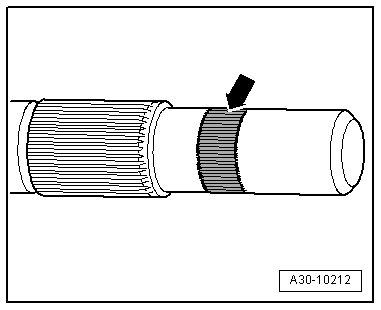

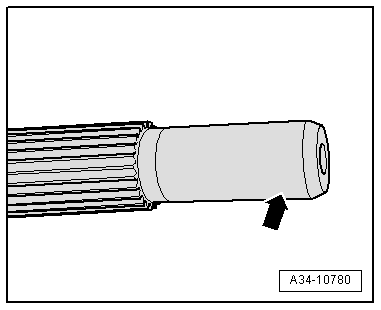

| Clutch pressure plates have an anti-corrosion coating and are greased. With the exception of the friction surface for the clutch plate, the pressure plate is not to be cleaned, as otherwise the service life of the clutch would be considerably shortened. |

| t

| The friction surface of the pressure plate and the dual-mass flywheel must be cleaned (degreased) thoroughly. |

| t

| If the clutch has burnt out, thoroughly clean the gearbox housing in area of clutch and parts of the engine facing the gearbox in order to prevent odours. |

| t

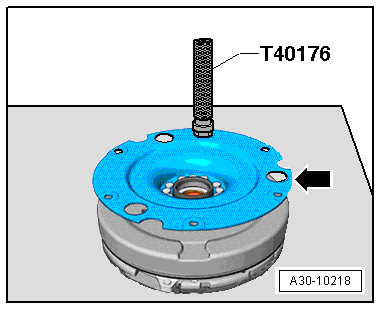

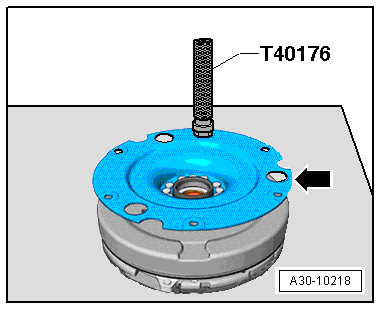

| The clutch module is only to be blown out using compressed air. |

|

|

|

Note

Note

Note

Note