A4 Mk3

| Special tools and workshop equipment required |

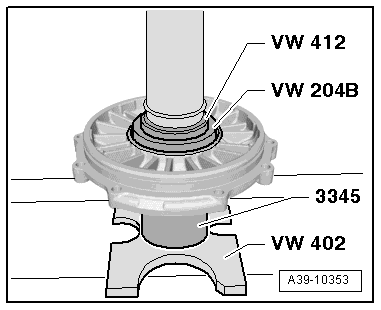

| t | Crankshaft seal installing tool -VW 204 B- |

| t | Drift -VW 295- |

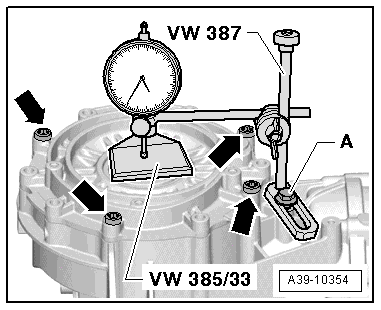

| t | Measuring plate -VW 385/33- |

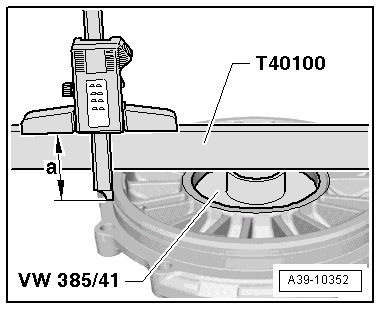

| t | Centring disc -VW 385/41- |

| t | Universal dial gauge bracket -VW 387- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 412- |

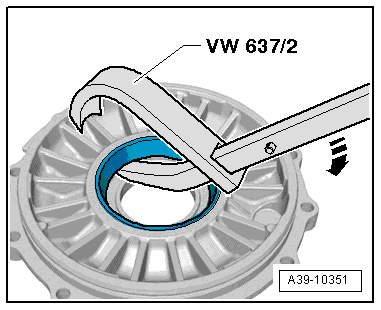

| t | Hub grease cap puller -VW 637/2- |

| t | Wheel bearing tube -3345- |

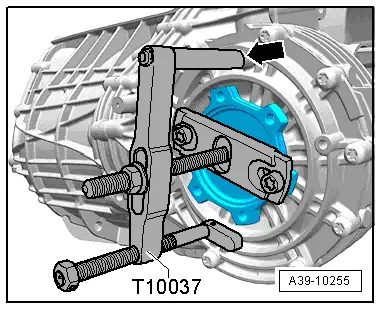

| t | Puller -T10037- |

| t | Ruler -T40100- |

|

|

|

|

|

Note

Note |

|

|

|

|

|

| Dimension -a- on old cover for final drive | 58.40 mm |

| Dimension -a- on new cover for final drive | 58.65 mm |

| Difference | = 0.25 mm |

|

| Existing shim | 1.50 mm |

| Difference | – 0.25 mm |

| New shim | = 1.25 mm |

Note

Note

|

Note

Note

|

|

|

|

|

|

|

|

|

|

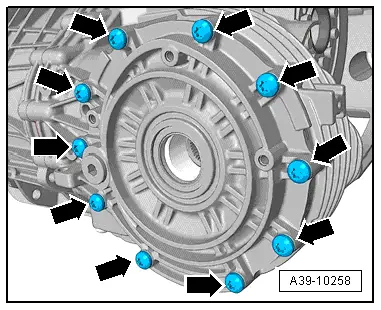

Caution

Caution