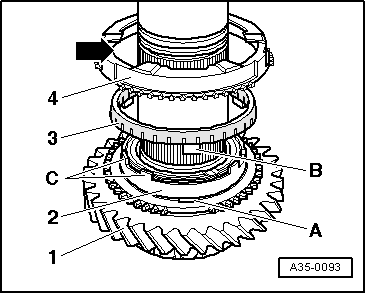

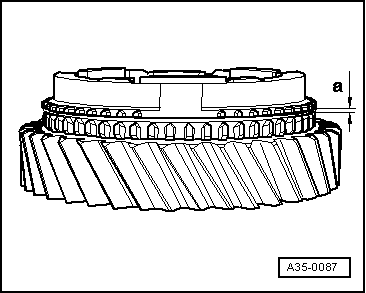

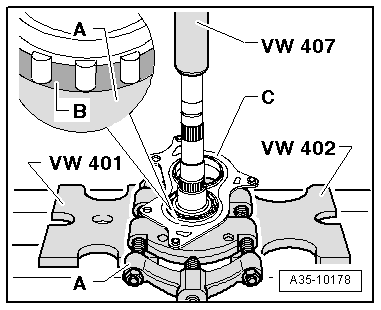

| Installation position of synchro-rings for 3rd to 6th gear |

Note | If components are not being renewed, make sure they are re-installed on the same gear. |

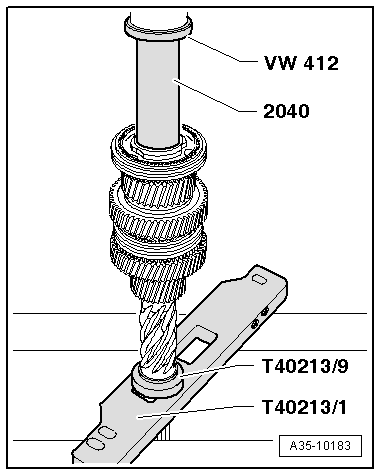

| –

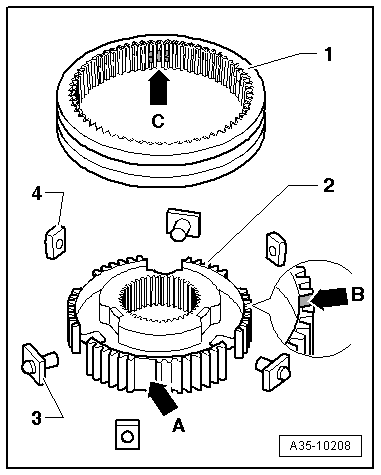

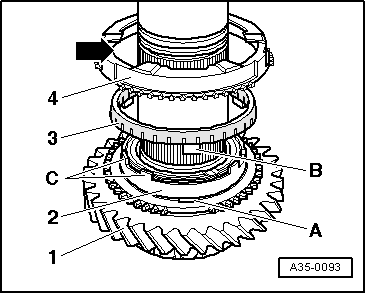

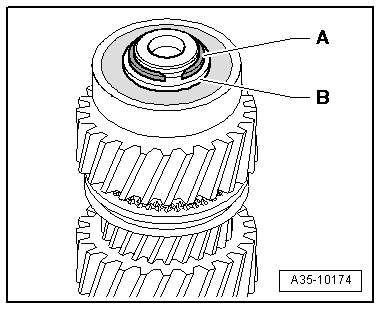

| Fit the inner ring -2- on the selector gear -1-. |

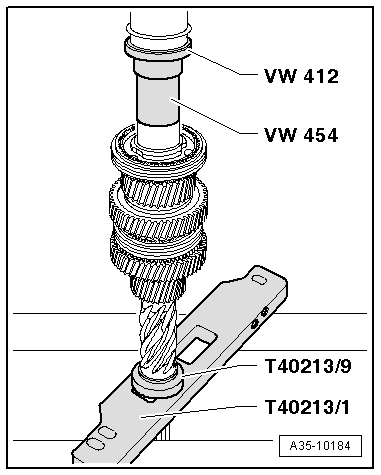

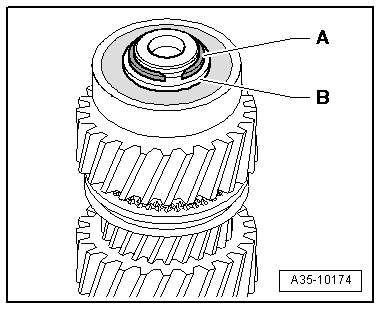

| –

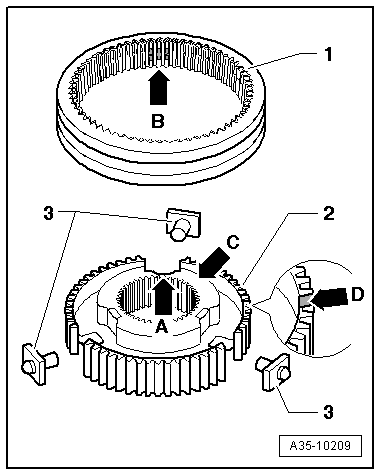

| Fit the intermediate ring -3-. The lug -B- must be inserted in the recess -A-. |

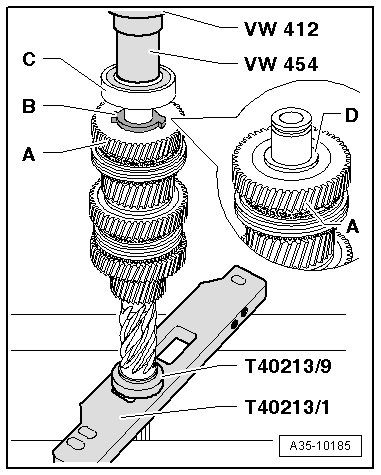

| –

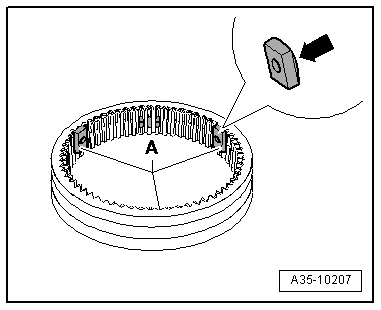

| Fit the synchro-ring -4-. Guide the lugs -C- through the recess -arrow-. |

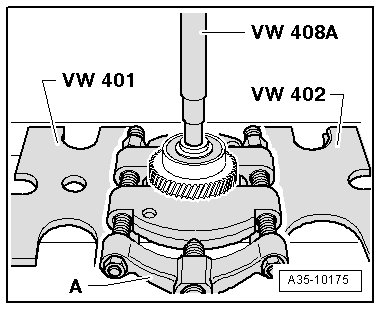

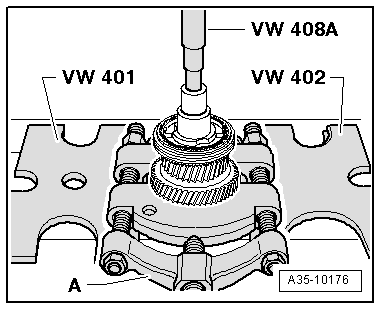

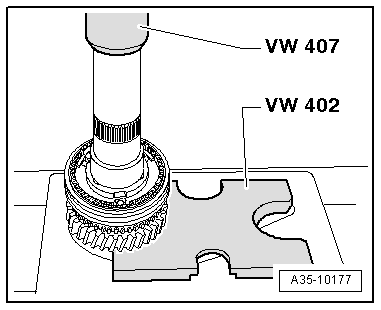

| Note the following when performing the following steps: |

| –

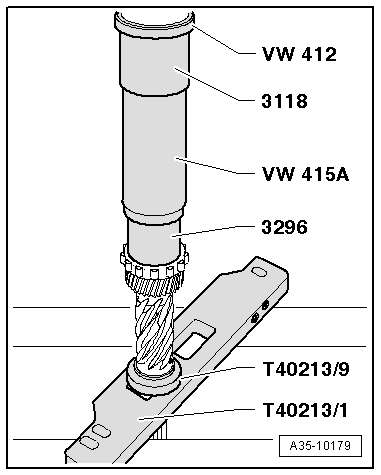

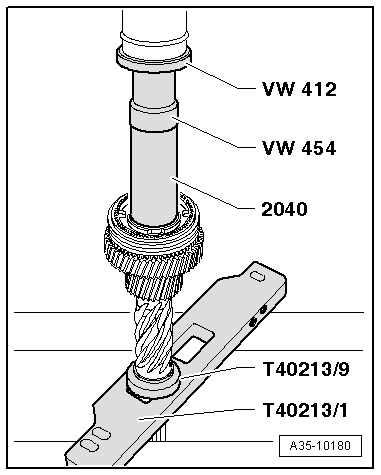

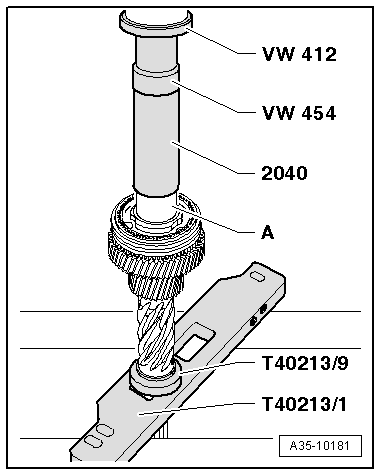

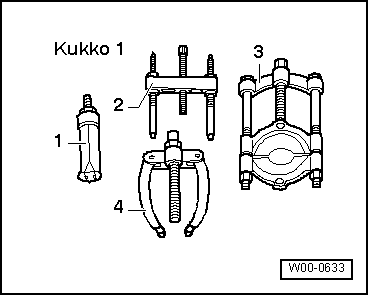

| Position drift sleeves on centre of heated components (synchronising hub and needle bearing inner races). |

| –

| First press on components just briefly, then stop exerting pressure and check whether drift sleeves are still positioned properly and press on as far as stop. |

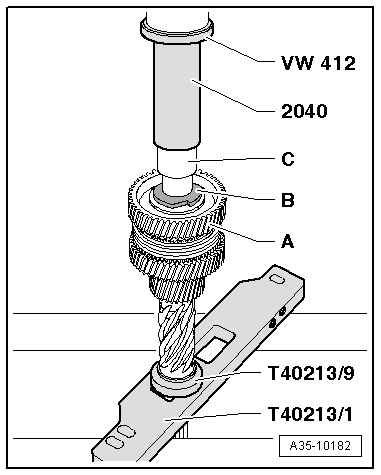

| When pressing on, the lugs of the synchro-ring and the recesses of the synchronising hub must coincide. To do so, lift the corresponding selector gear with synchro-rings slightly to lock it in the recesses of the synchronising hub. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note