A4 Mk3

| Fitting sequence - detaching selector fork cluster, input shaft, first, second and reverse gear from output shaft/attaching |

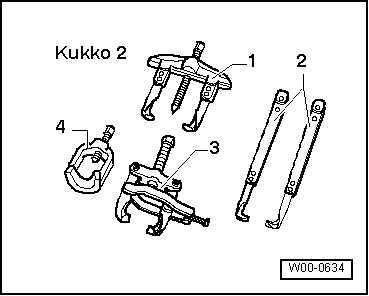

| Special tools and workshop equipment required |

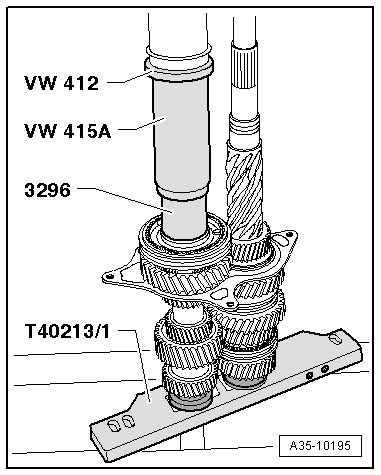

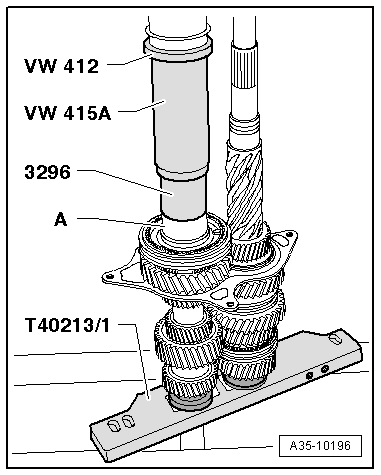

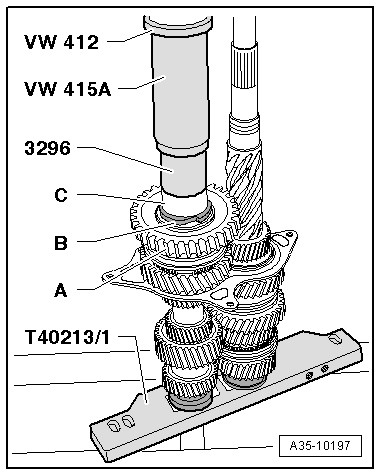

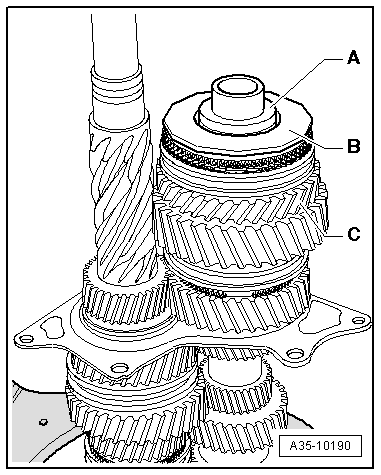

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

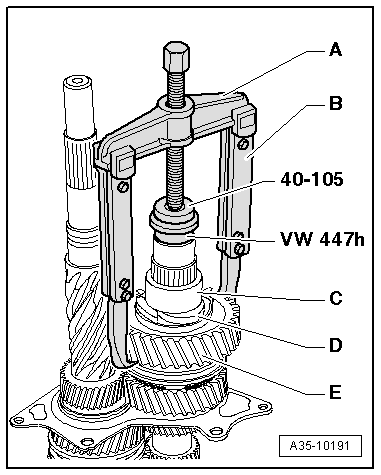

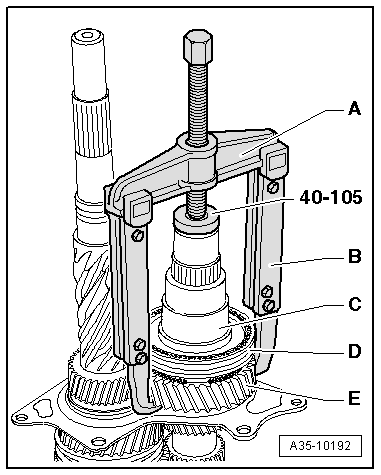

| t | Thrust pad -VW 447 H- |

| t | Thrust plate -40 - 105- |

| t | Tube -3296- |

| t | Workshop press -V.A.G 1290A- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Caution

Caution