| –

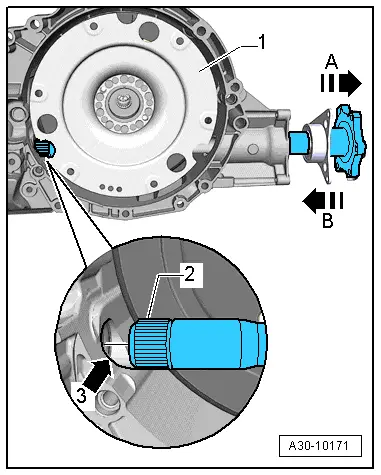

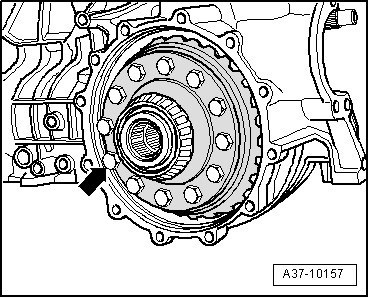

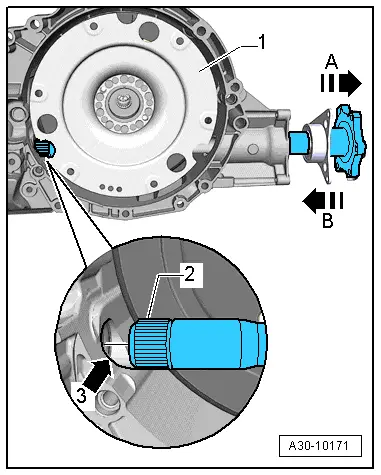

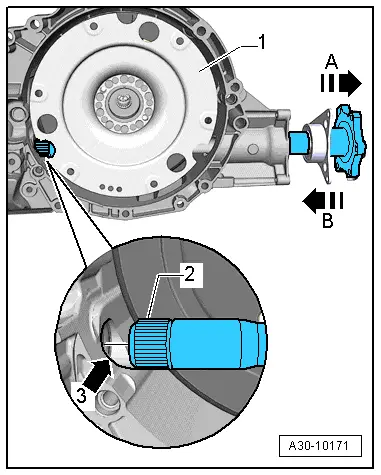

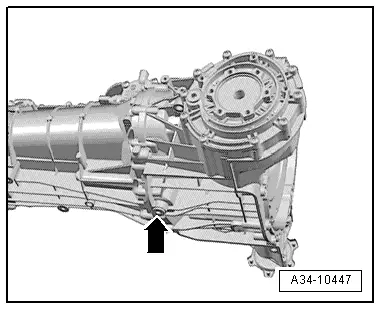

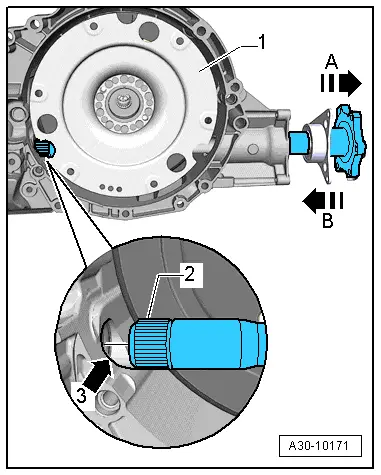

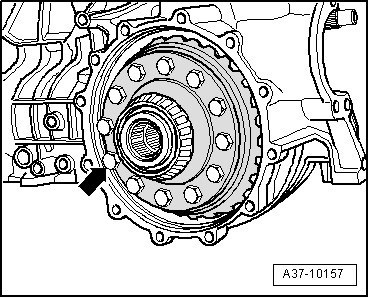

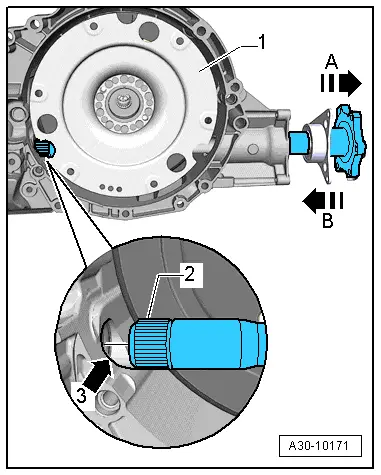

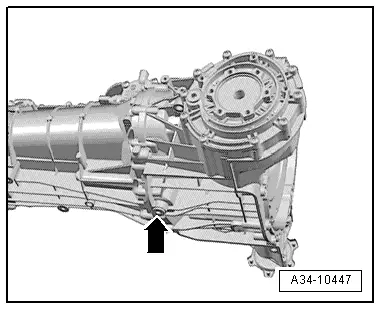

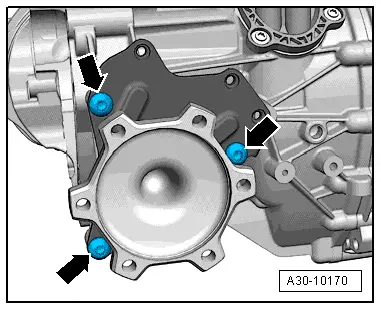

| Turn clutch module -1- so that you can see opening to differential -arrow 3-. |

| –

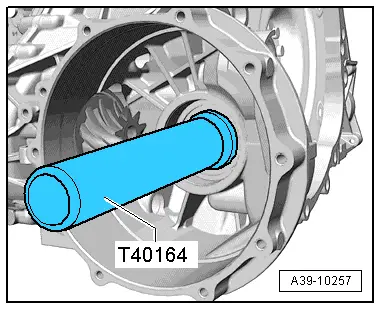

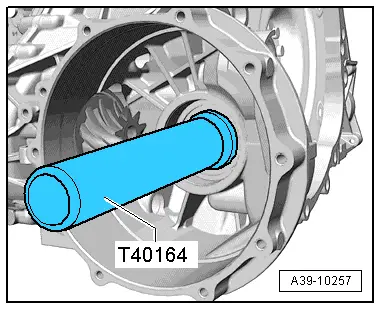

| Thoroughly clean flange shaft (left-side) -2-. |

| –

| Slide flange-shaft (left-side) -2- into gearbox in direction of -arrow B- (keep end of shaft centered while guiding it into oil seal on front final drive -arrow 3-). |

Caution | Risk of damage to oil seal. |

| t

| If you do not keep the shaft centered, the splines of the shaft -2- will damage the oil seal -arrow 3- between the differential and the gearbox housing. |

| t

| If oil seal is damaged, it must be renewed → Chapter. |

|

|

|

|

Note

Note

Note

Note