| –

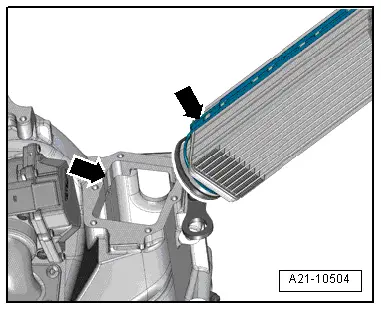

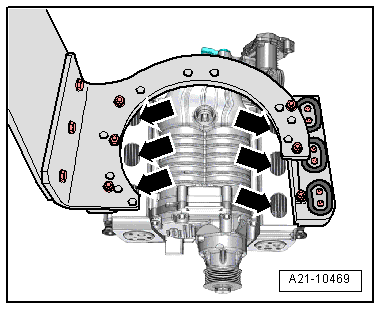

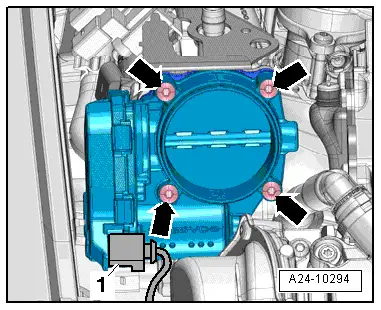

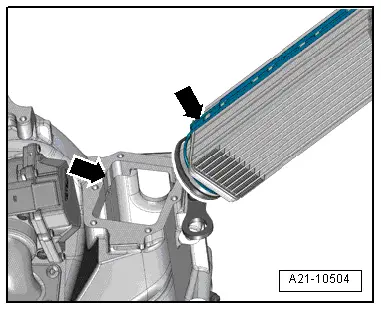

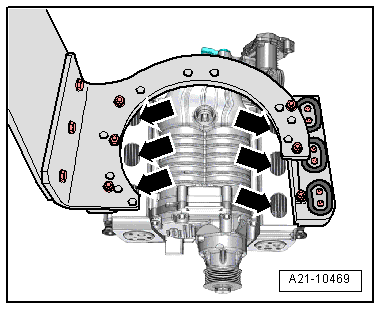

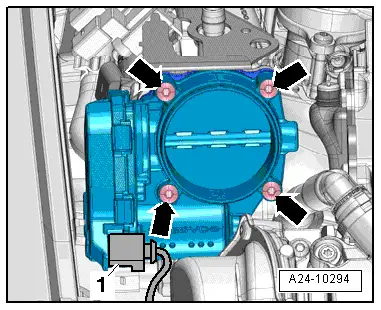

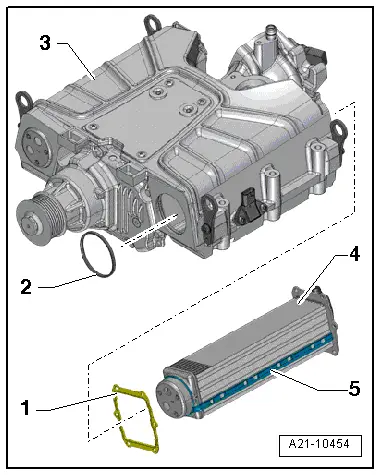

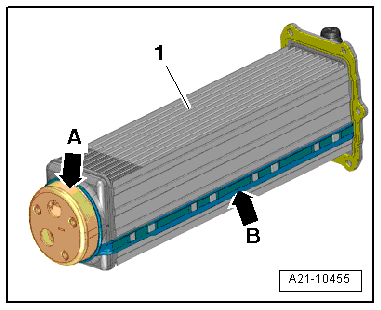

| If necessary, guide charge air cooler by hand via openings -arrows- in supercharger housing when inserting cooler. |

| –

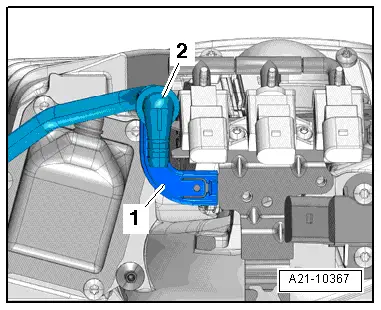

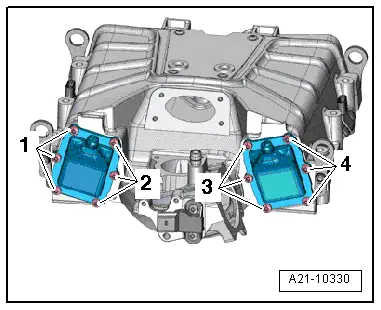

| As soon as possible (due to length of bolts), screw in 2 bolts loosely by hand to guide charge air cooler additionally. |

Caution | Risk of damage to charge air cooler. |

| t

| The charge air cooler must not be pulled in by screwing in the securing bolts. |

| t

| Insert charge air cooler by hand (without using tools) until sealing flange with gasket makes contact with supercharger housing (maximum: 1 mm distance). Only then tighten bolts, as described in the following. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note