| –

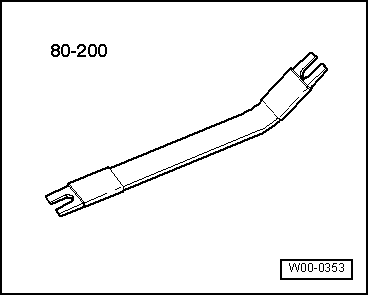

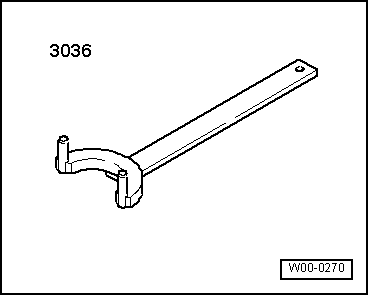

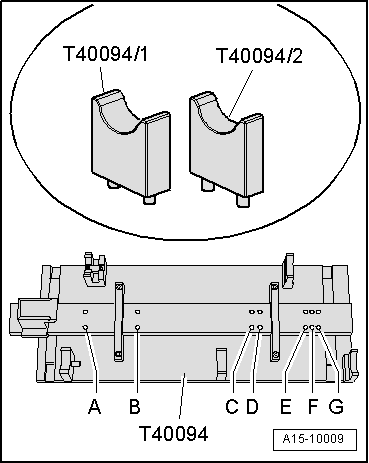

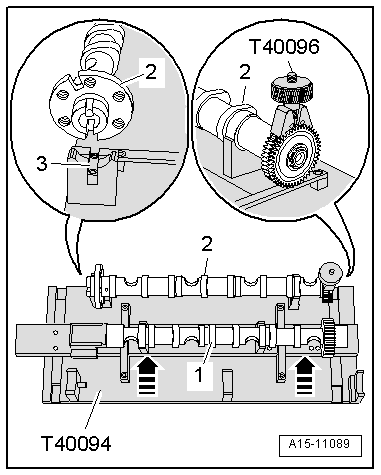

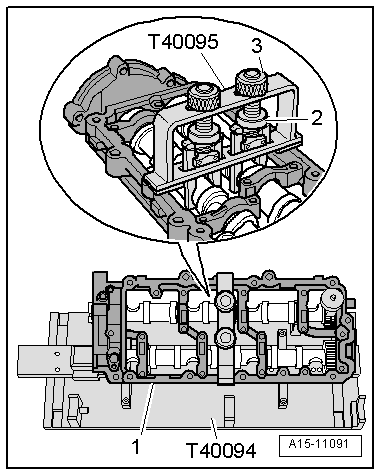

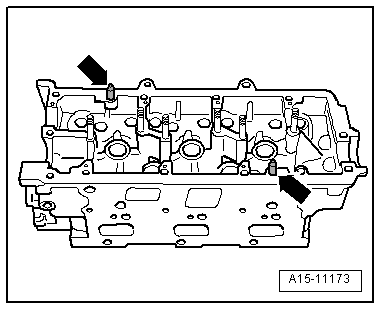

| Fit retaining frame together with both camshafts and camshaft fitting tool -T40095- onto cylinder head. |

| –

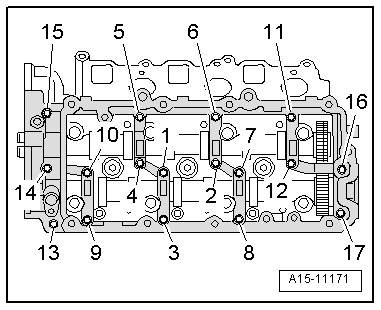

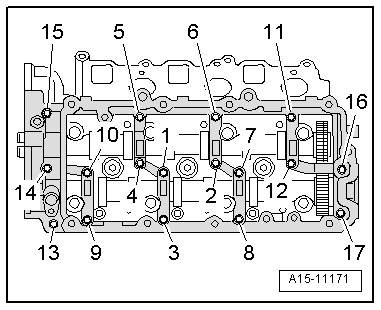

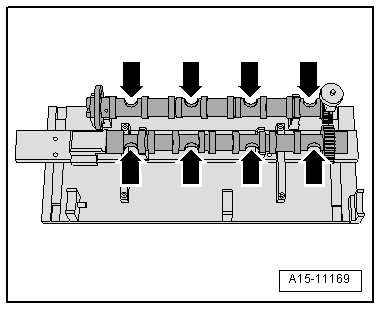

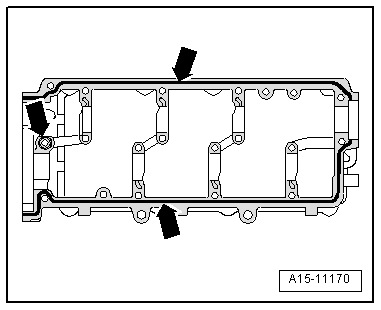

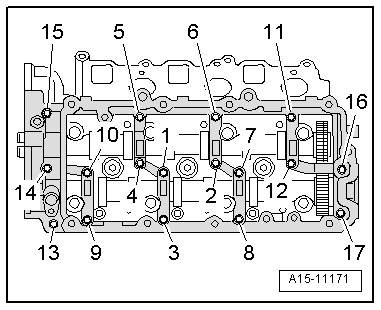

| Tighten bolts for retaining frame → Fig.. |

| –

| Remove camshaft fitting tool -T40095- and -T40096-. |

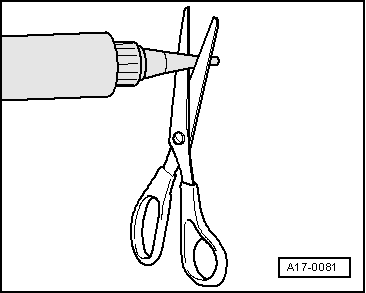

Note | After installing the retaining frame, wait about 30 minutes for the sealant to dry. |

| Remaining installation steps are carried out in reverse sequence; note the following: |

| –

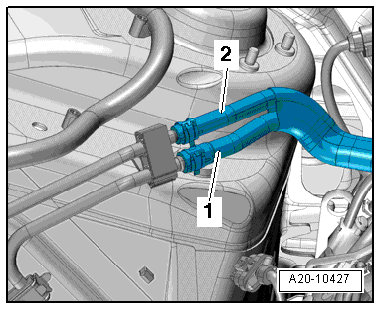

| Install cylinder head cover (right-side) → Chapter. |

| –

| Use suitable drift to drive in new sealing cap until flush. |

| –

| Install camshaft timing chain: engine codes CAMA, CAMB, CCLA, CCWA, CCWB, CGKA, CGKB → Anchor, engine code CAPA → Anchor. |

Caution | Avoid damage to valves and piston crowns after working on valve gear. |

| t

| The hydraulic tappets have to settle; wait for approx. 30 minutes after installing camshafts before starting engine. |

| t

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING