A4 Mk3

| Poly V-belt drive - exploded view |

| 1 - | Poly V-belt |

| q | Check for wear |

| q | Before removing, mark direction of rotation with chalk or felt-tip pen |

| q | Removing and installing → Chapter |

| q | Do not kink |

| q | When installing, make sure it is properly seated on pulleys |

| 2 - | Bolt |

| q | Renew |

| q | 20 Nm + turn 90° further |

| 3 - | Shim |

| q | Renew |

| 4 - | Cover for idler roller (right-side) |

| 5 - | Alternator |

| q | Removing and installing → Electrical system; Rep. gr.27 |

| 6 - | Bolt |

| q | Tightening torque → Electrical system; Rep. gr.27 |

| 7 - | Cover for idler roller |

| 8 - | Bolt |

| q | 23 Nm |

| 9 - | Idler roller for poly V-belt |

| q | On bracket for alternator |

| q | Note installation position |

| 10 - | Bolt |

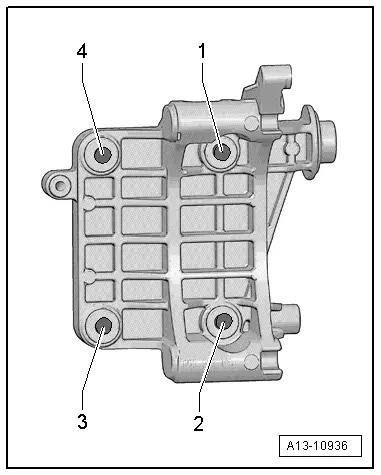

| q | Tightening torque and sequence → Fig. |

| 11 - | Bracket for alternator and idler roller |

| 12 - | Bolt |

| q | 23 Nm |

| 13 - | Idler roller (right-side) for poly V-belt |

| q | Note installation position |

| 14 - | Cover for idler roller (left-side) |

| q | Depending on version → Electronic parts catalogue |

| 15 - | Bolt |

| q | Depending on version → Electronic parts catalogue |

| q | 23 Nm |

| 16 - | Bolt |

| q | Tightening torque → Item |

| 17 - | Poly V-belt pulley for coolant pump |

| q | Removing and installing → Chapter „Removing and installing coolant pump“ |

| q | Installation position: marking „vorne“ (front) faces in direction of travel |

| 18 - | Bolt |

| q | Tightening torque and sequence → Fig. |

| 19 - | Coolant pump |

| q | Removing and installing → Chapter |

| 20 - | Idler roller (left-side) for poly V-belt |

| q | Depending on version → Electronic parts catalogue |

| q | Removing and installing → Chapter |

| 21 - | Bolt |

| q | Depending on version → Electronic parts catalogue |

| q | 23 Nm |

| 22 - | Bracket for idler roller |

| q | Depending on version → Electronic parts catalogue |

| 23 - | Bolt |

| q | Tightening torque → Rep. gr.48 |

| 24 - | Power steering pump |

| q | Removing and installing → Rep. gr.48 |

| 25 - | Poly V-belt pulley for power steering pump |

| q | Removing and installing → Rep. gr.48 |

| q | Installation position: marking „vorne“ (front) faces in direction of travel |

| 26 - | Bolt |

| q | Tightening torque → Rep. gr.48 |

| 27 - | Gasket |

| q | Renew |

| 28 - | Bracket for ancillaries |

| q | Removing and installing → Chapter |

| 29 - | Bolt |

| q | 40 Nm |

| 30 - | Bolt |

| q | Tightening torque → Rep. gr.87 |

| 31 - | Air conditioner compressor |

| q | Do not unscrew or disconnect refrigerant hoses or pipes |

| q | Removing and installing → Rep. gr.87 |

| q | When installing check dowel sleeves -item 32- |

| 32 - | Dowel sleeve |

| q | 2x |

| q | Check for correct seating in bracket for ancillaries |

| 33 - | Bolt |

| q | 23 Nm |

| 34 - | Poly V-belt tensioner |

Caution

Caution

|

| q | Removing and installing → Chapter |

| 35 - | Bolt |

Caution

Caution

|

| q | Bolt with M10 thread: 50 Nm + turn 90° further |

| q | Bolt with M11 thread: 60 Nm + turn 90° further |

| q | Renew |

| 36 - | Vibration damper with poly V-belt pulley |

| q | Removing and installing → Chapter |

|

|