WARNING | Safety risk from escaping fuel: the fuel delivery unit is still filled. |

| Use a cloth to catch escaping fuel. |

|

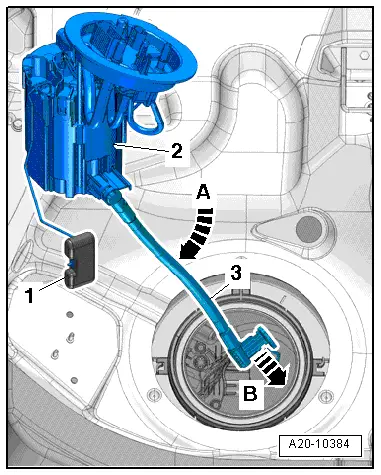

| –

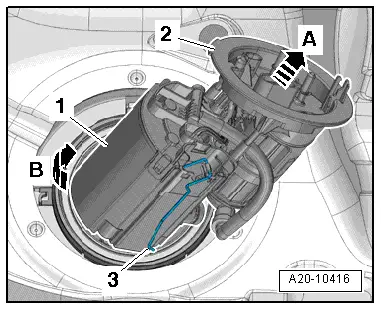

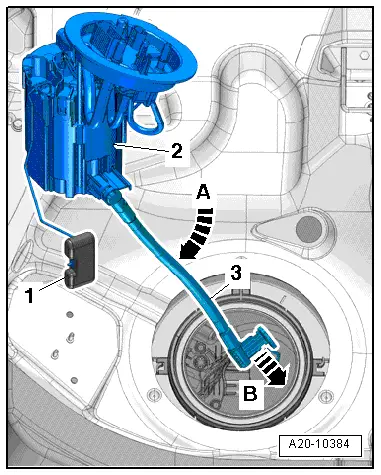

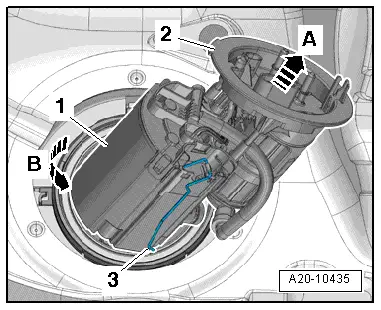

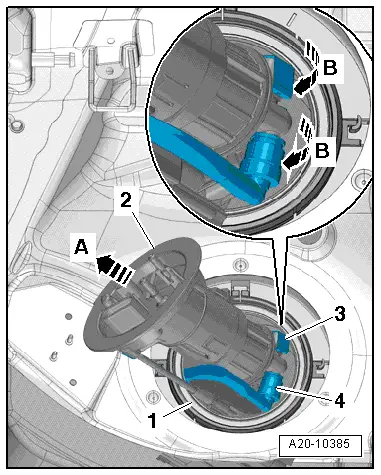

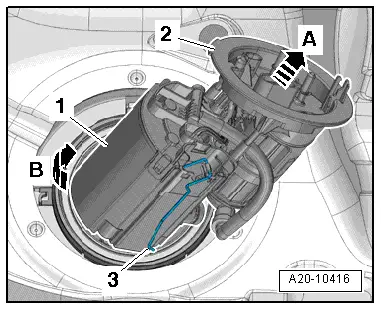

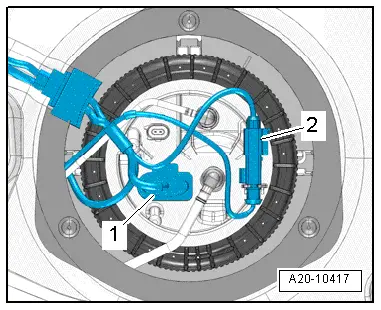

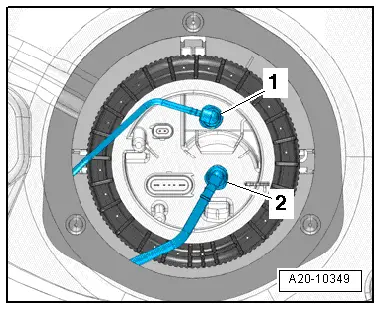

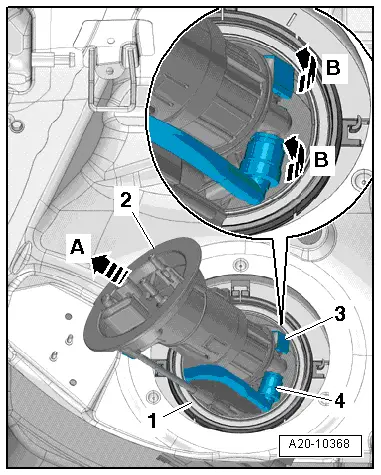

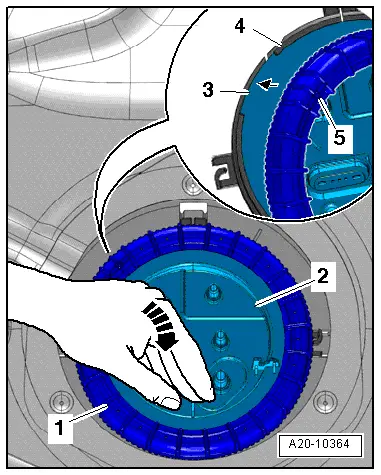

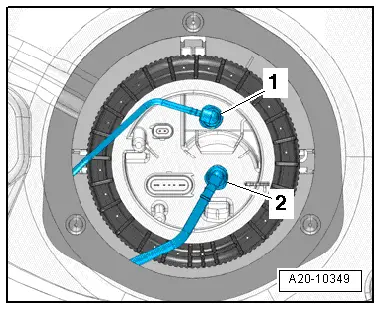

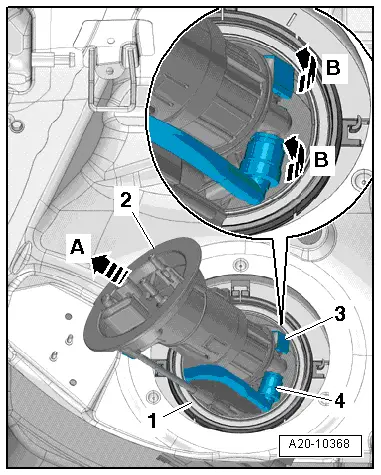

| Pull flange -2- with fuel filter a bit further away from fuel delivery unit -1--arrow A-. |

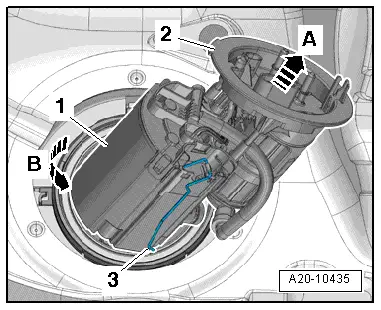

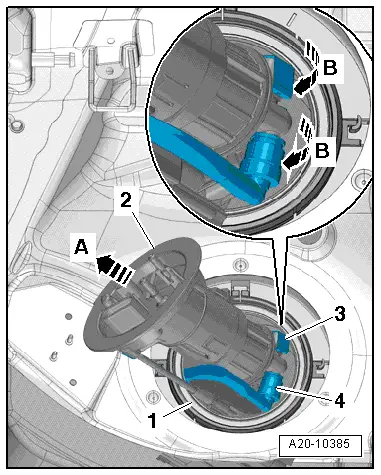

| –

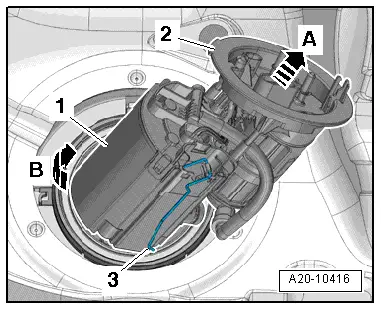

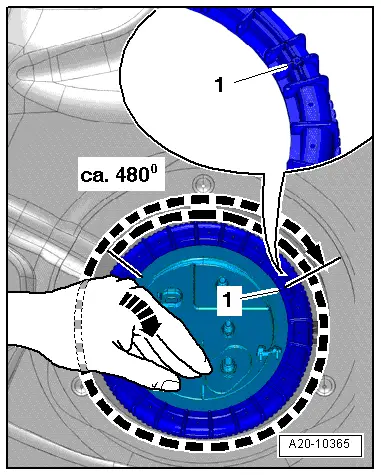

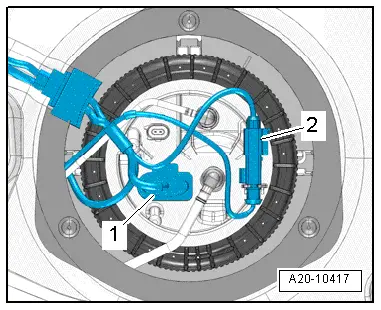

| Swivel fuel delivery unit to left side of vehicle -arrow B- and tilt slightly out of fuel tank. |

Note | When removing fuel delivery unit, make sure you do not bend float arm of fuel gauge sender -G-. |

| –

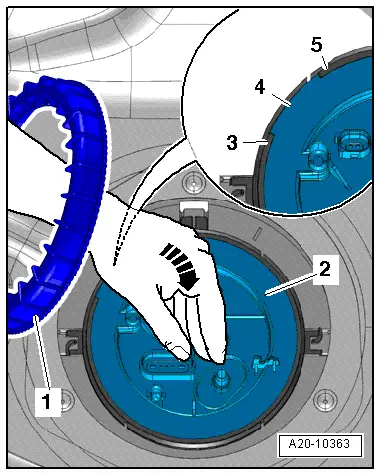

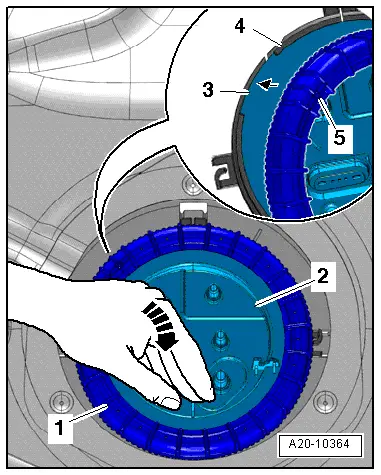

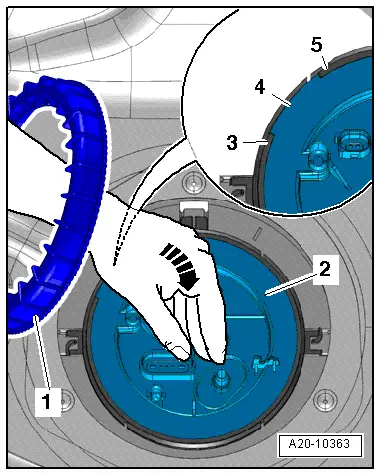

| Pull fuel gauge sender -G--item 3- out of opening in fuel tank and remove fuel delivery unit with suction pipe from fuel tank. |

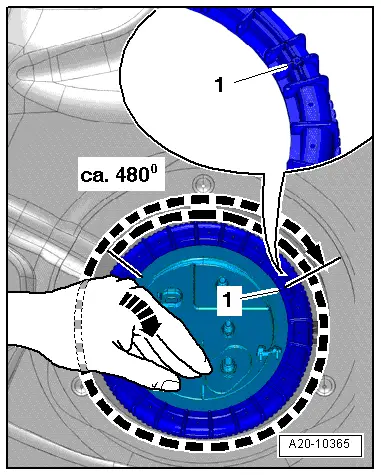

| Installation is carried out in the reverse order; note the following: |

Note | t

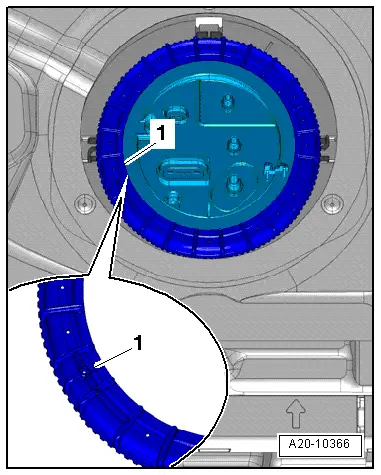

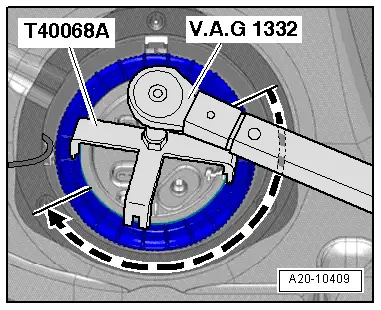

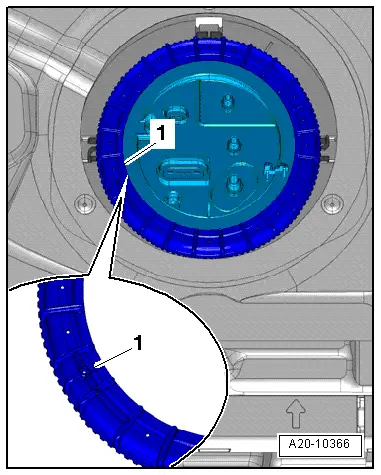

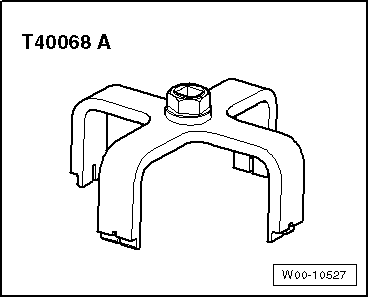

| Renew seal and union nut. |

| t

| When installing fuel delivery unit, take care not to bend float arm of fuel gauge sender -G-. |

| t

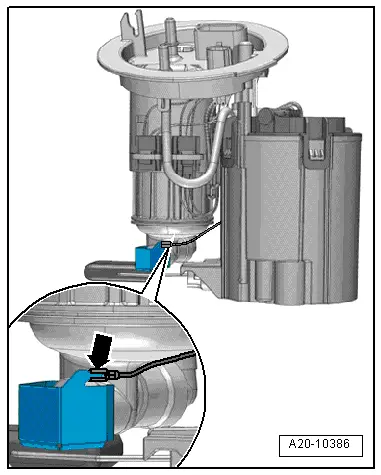

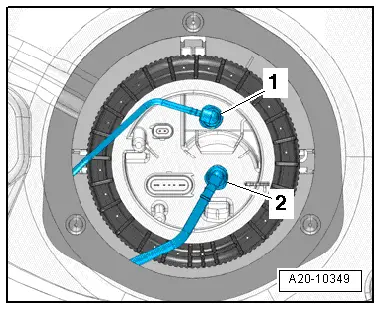

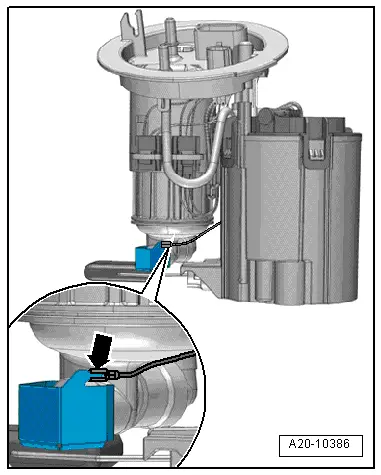

| Make sure that fuel lines are securely fitted. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note