| –

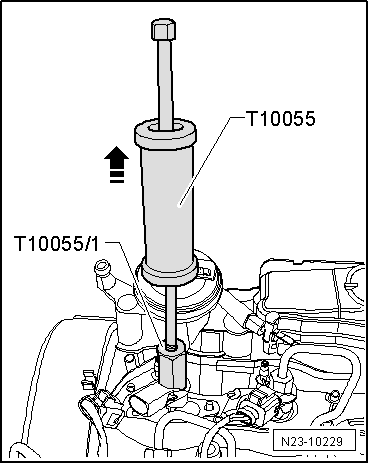

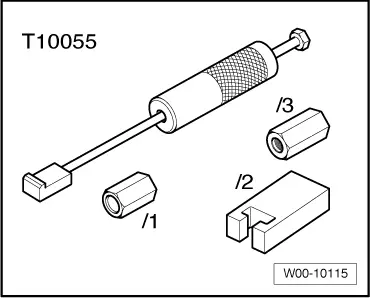

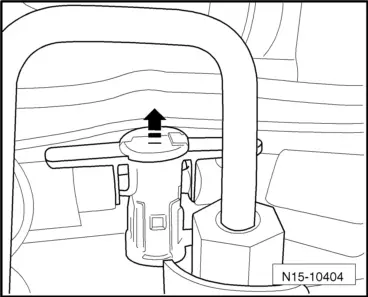

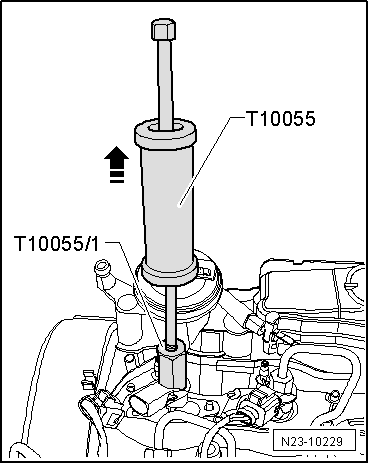

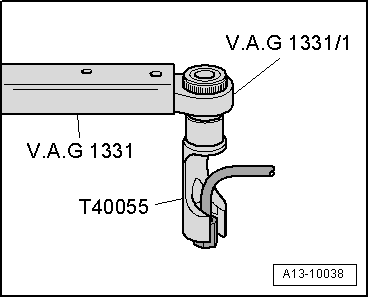

| Apply puller -T10055- with adapter -T10055/1- as shown in illustration and pull injector out upwards by tapping gently. |

| –

| After removal, lay injectors on a clean cloth. |

| When installing new injectors, the following components must be renewed: |

| t

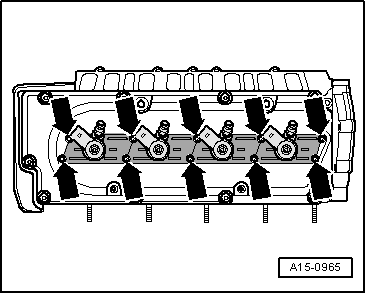

| Renew O-ring for injector bore. |

| t

| O-ring for fuel return line connection |

Note | t

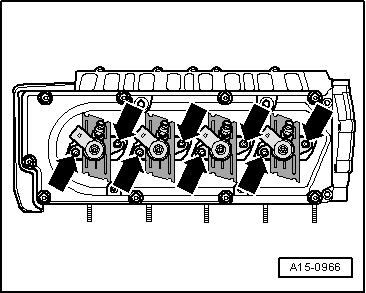

| Note identification marks for cylinder allocation when re-installing high-pressure pipes. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check taper seats of high-pressure pipes for deformation and cracks. |

| t

| The bore of the pipe must not be distorted, restricted or otherwise damaged. |

| t

| Corroded pipes must not be used again. |

| Installing used injectors |

| When re-installing used injectors, the following components must be renewed: |

| t

| Renew O-ring for injector bore. |

| t

| O-ring for fuel return line connection |

| –

| Spray tip of injector nozzle with rust-releasing spray. Wait approx. 5 minutes and wipe off soot particles and oil with a cloth. |

| –

| If an injector is very dirty, the tip of the nozzle should also be cleaned with a soft brass wire brush to make it easier to remove the copper seal. Do not apply the wire brush to the bores in the nozzle. |

| –

| To remove the old copper seal from the injector, clamp the seal carefully in a vice so that it is just held between the jaws without turning. Then carefully pull and twist the injector out of the copper seal by hand. |

| –

| Clean off deposits under the copper seal using a suitable scraper. |

Caution | Risk of damage to injector sealing surface. |

| To remove carbon deposits from the injector sealing surface, clean the injector bore in the cylinder head with a cloth soaked in engine oil or rust solvent. |

|

|

|

|

Note

Note

Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution