| –

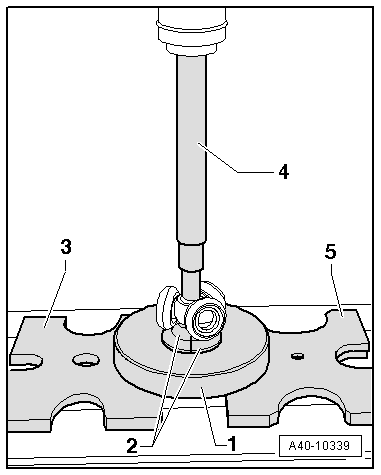

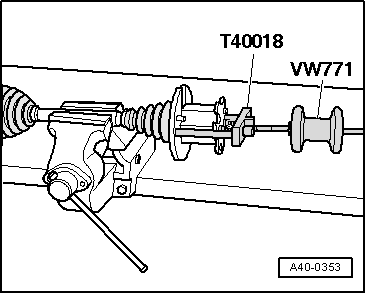

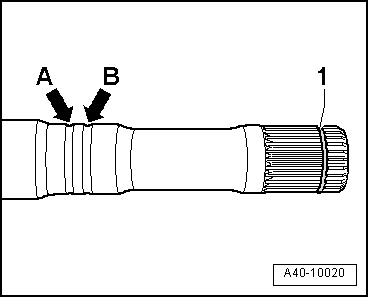

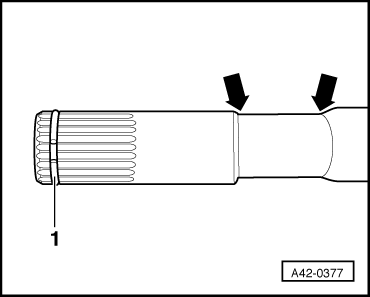

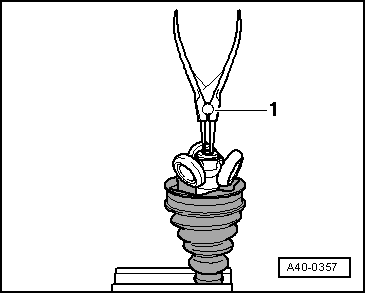

| Press triple roller spider off drive shaft. |

| –

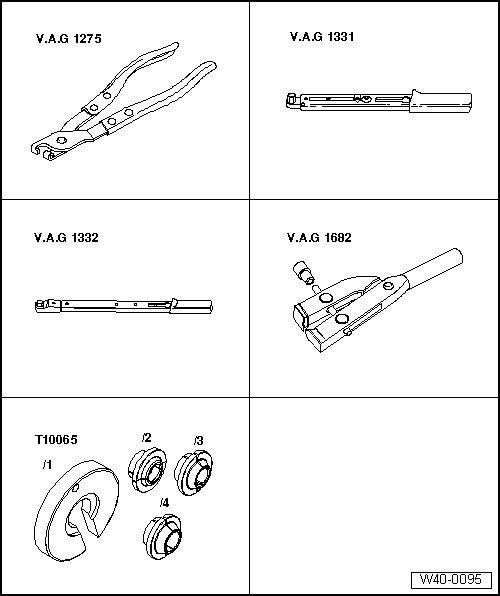

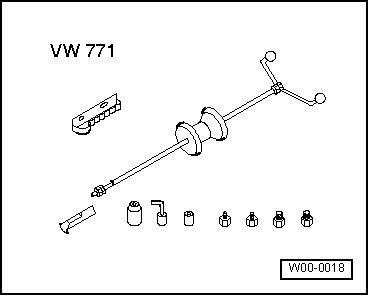

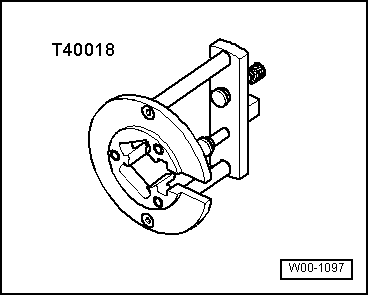

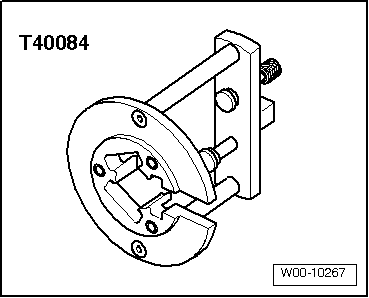

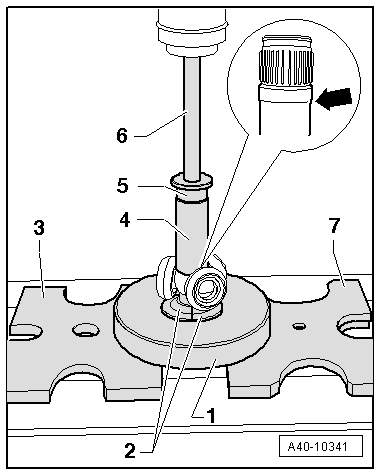

| Use the special tools shown in the illustration. |

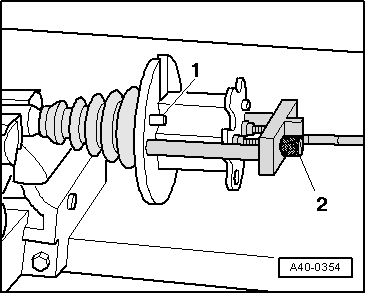

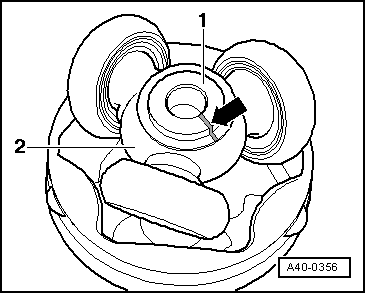

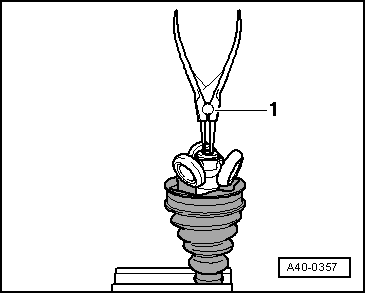

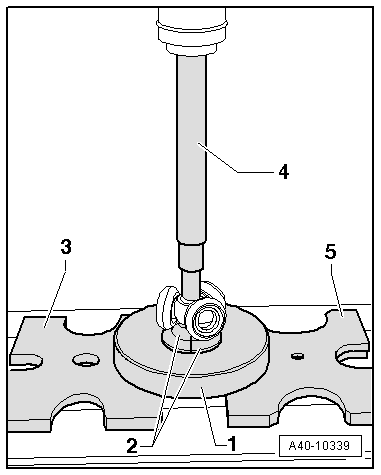

| 1 - | Assembly tool -T10065/1- |

| 2 - | Assembly tool -T10065/5-, must make contact with base of triple roller spider |

| 3 - | Thrust plate -VW 401- |

| 4 - | Press tool -VW 408 A- |

| 5 - | Thrust plate -VW 402- |

| Assembly tool -T10065/5--2- must not rest on rollers (swivel the rollers aside if necessary). |

| –

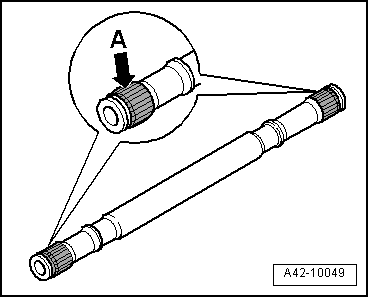

| Remove grease from shaft splines. |

| –

| Check rollers and roller races for wear. |

| –

| Clean drive shaft and housing. |

| Assembling triple roller joint AAR 2600 i or 3300 i |

| –

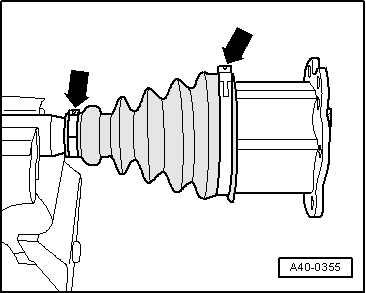

| Push on small hose clip with joint boot and bring boot into position on drive shaft (position varies depending on version). |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution