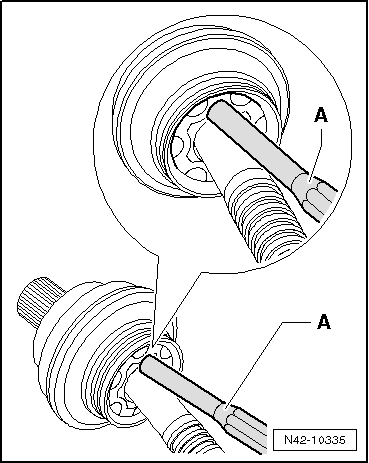

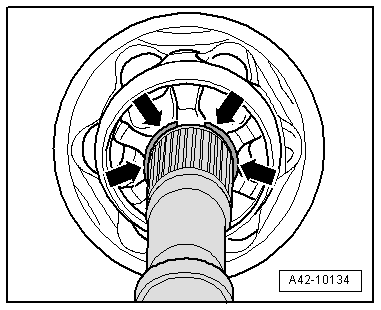

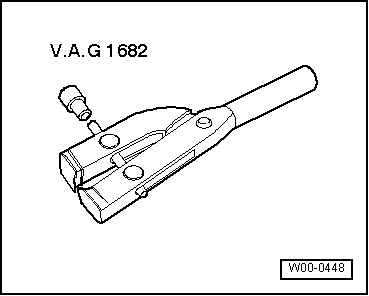

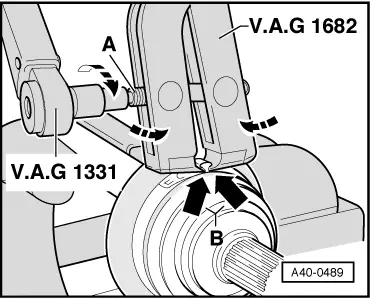

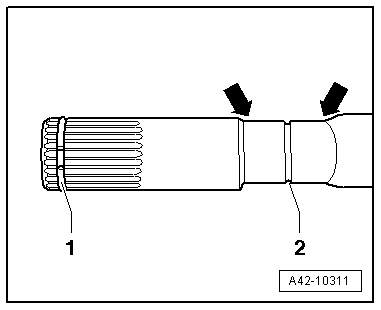

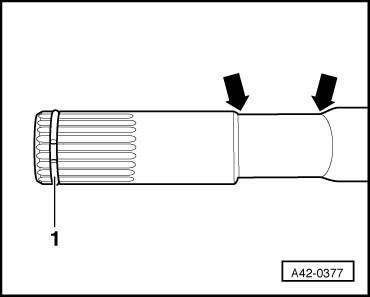

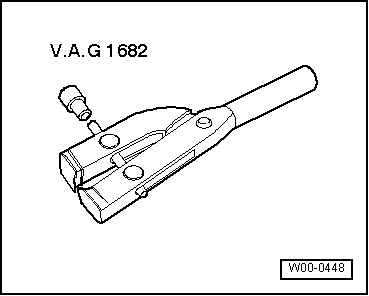

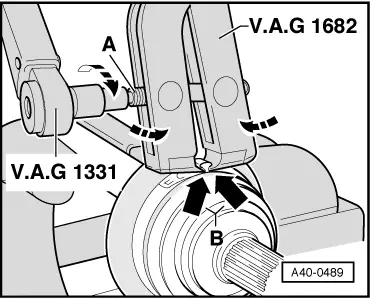

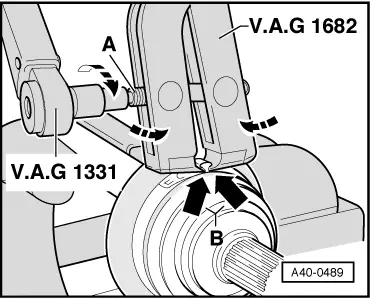

| Use clamp tensioner -V.A.G 1682- to fit and tighten stainless steel clips, as shown in illustration. |

| –

| Ensure jaws of tool make contact with lugs -arrows B- on hose clip. |

| –

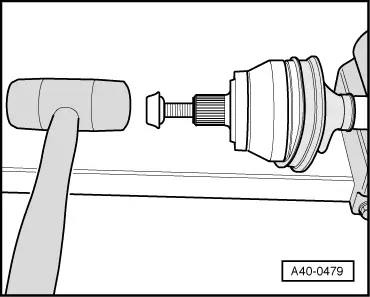

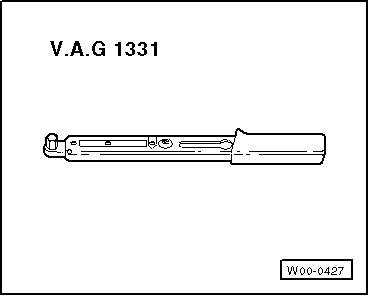

| Tighten hose clip by turning spindle with torque wrench (take care to keep clamp tensioner straight). |

| t

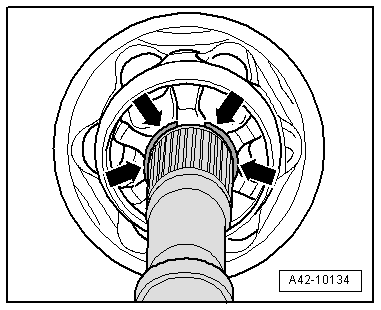

| Due to the hard material of the CV joint boot (as opposed to rubber), a stainless steel hose clip is required; this can only be tightened using clamp tensioner -V.A.G 1682-. |

| t

| Tightening torque: 20 Nm. |

| t

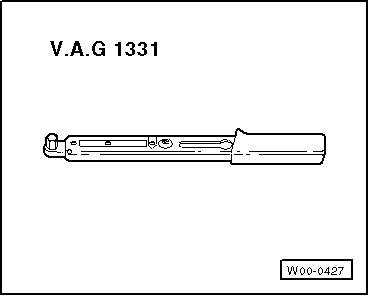

| Use torque wrench with 5…50 Nm adjustment range (e.g. -V.A.G 1331-). |

| t

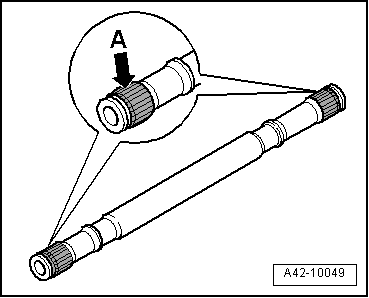

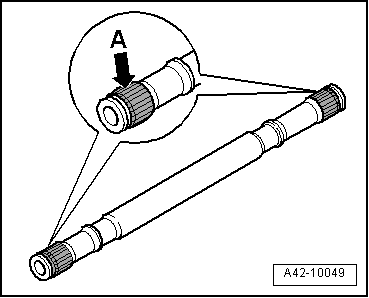

| Make sure thread of spindle on tool -A- turns freely. Lubricate with MoS2 grease if necessary. |

| t

| If the thread is stiff (e.g. due to dirt), the required clamping force will not be attained at the hose clip when the specified tightening torque is applied. |

|

|

|