A4 Mk3

| Exploded view of subframe, anti-roll bar, coupling rod - four-wheel drive vehicles |

| 1 - | Clamp |

| q | Is renewed together with rubber bush and anti-roll bar |

| q | Rubber bush and clamp must not be separated from anti-roll bar |

| 2 - | Bolt |

| q | 25 Nm +90° |

| q | Always renew if removed |

| q | Tighten evenly |

| 3 - | Bolt |

| q | 40 Nm +90° |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 4 - | Bolt |

| q | 40 Nm +90° |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 5 - | Coupling rod |

| q | Coupling rod is removed together with anti-roll bar |

| q | Removing and installing → Chapter |

| 6 - | Nut |

| q | Always renew if removed |

| 7 - | Anti-roll bar |

| q | Anti-roll bar is removed together with coupling rod |

| q | Removing and installing → Chapter |

| q | Rubber bush and clamp must not be separated from anti-roll bar |

| 8 - | Bolt |

| q | 70 Nm +180° |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 9 - | Retaining bracket |

| 10 - | Bolt |

| q | 5 Nm |

| 11 - | Nut |

| q | Always renew if removed |

| 12 - | Upper transverse link |

| 13 - | Bolt |

| q | 115 Nm +90° |

| q | Always renew if removed |

| q | Bolts must not be loosened or tightened while springs are still installed. Before loosening or tightening bolts, slacken coil springs using spring compressor |

| 14 - | Rear left vehicle level sender -G76- |

| q | The same sender versions must be installed on both sides. |

| q | Complete with mounting parts |

| q | Lever of sender must face outwards |

| q | Renewing in vehicle → Chapter |

| q | Check basic adjustment of headlights if sender mountings are loosened → Rep. gr.94 |

| q | If, on vehicles with electronic damping control, the vehicle level sender has been removed and refitted or the linkage detached, the reference position must be re-adapted → Chapter. → Vehicle diagnostic, testing and information system VAS 5051 |

| q | If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

| 15 - | Bolt |

| q | 9 Nm |

| 16 - | Bolt |

| q | 70 Nm +180° |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 17 - | Lower transverse link |

| 18 - | Nut |

| q | Always renew if removed |

| 19 - | Bolt |

| q | 70 Nm +180° |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 20 - | Track rod |

| q | Different versions (aluminium and steel); for correct version, refer to → Electronic parts catalogue |

| q | Mixed installation is not permissible |

| 21 - | Eccentric bolt |

| 22 - | Nut |

| q | 95 Nm |

| q | Always renew if removed |

| q | Vehicle must be in unladen position when tightening → Chapter |

| 23 - | Eccentric washer |

| 24 - | Support (left-side) |

| 25 - | Bolt |

| q | 55 Nm |

| 26 - | Bolt |

| q | 115 Nm +90° |

| q | Always renew if removed |

| q | Bolts must not be loosened or tightened while springs are still installed. Before loosening or tightening bolts, slacken coil springs using spring compressor |

| 27 - | Clip |

| q | Not fitted on all vehicles |

| 28 - | Stone deflector (left-side) |

| q | Not fitted on all vehicles |

| 29 - | Stone deflector (centre) |

| q | Not fitted on all vehicles |

| 30 - | Stone deflector (right-side) |

| q | Not fitted on all vehicles |

| 31 - | Bolt |

| q | Tightening torque → Rep. gr.39 |

| 32 - | Rear final drive |

| q | Removing and installing → Rep. gr.39 |

| 33 - | Cross member for differential |

| q | Removing and installing → Rep. gr.39 |

| q | Not fitted on vehicles with sport differential |

| 34 - | Bolt |

| q | Tightening torque → Rep. gr.39 |

| 35 - | Support (right-side) |

| 36 - | Bonded rubber bush (front) |

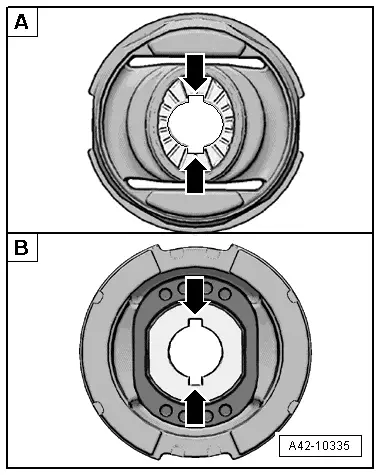

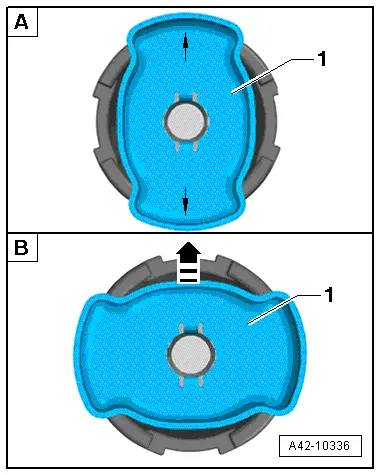

| q | For subframe mounting |

| q | Different types of bonded rubber bush (conventional or hydraulic) are fitted, depending on model → Anchor; for correct version refer to → Electronic parts catalogue |

| q | Oil stains on a hydraulic bonded rubber bush are a sign of wear |

| q | Renewing → Chapter |

| q | Always renew on both sides |

| 37 - | Spacer |

| q | Fitted on allroad |

| q | Note installation position: ribbed side faces body |

| 38 - | Subframe |

| q | Removing and installing subframe with attachments → Chapter |

| 39 - | Bonded rubber bush (front) |

| q | For rear final drive mounting |

| q | Renewing → Chapter |

| 40 - | Bonded rubber bush (rear) |

| q | For rear final drive mounting |

| q | Renewing → Chapter |

| 41 - | Bonded rubber bush (rear) |

| q | For subframe mounting |

| q | Different types of bonded rubber bush (conventional or hydraulic) are fitted, depending on model → Anchor; for correct version refer to → Electronic parts catalogue |

| q | Oil stains on a hydraulic bonded rubber bush are a sign of wear |

| q | Renewing → Chapter |

| q | Always renew on both sides |

| 42 - | Spacer |

| q | Fitted on allroad |

| q | Note installation position: ribbed side faces body |

| 43 - | Bonded rubber bush (rear) |

| q | For rear final drive mounting |

| q | Renewing → Chapter |

| 44 - | Bolt |

| q | Tightening torque → Rep. gr.39 |

|

|

|

|