Note | t

| If a bonded rubber bush on one side is defective, the bush on the other side must be renewed at the same time. For correct version refer to → Electronic parts catalogue. |

| t

| Also check the other bushes before renewing a defective bonded rubber bush. |

| t

| If cracks, oil stains or other damage is visible, these bonded rubber bushes must also be renewed. |

| –

| Raise vehicle on lifting platform. |

Note | t

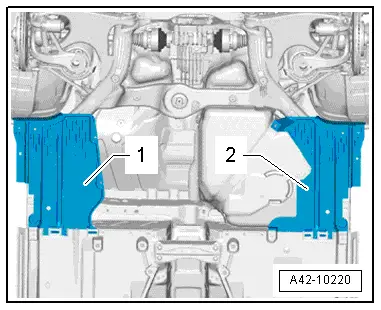

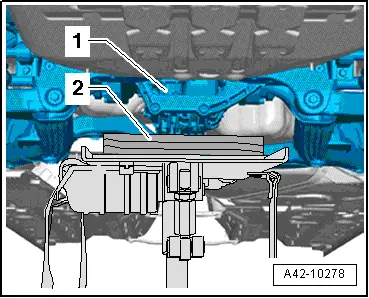

| The front or rear part of the subframe is lowered in order to renew the bonded rubber bushes. The subframe does not have to be removed. |

| t

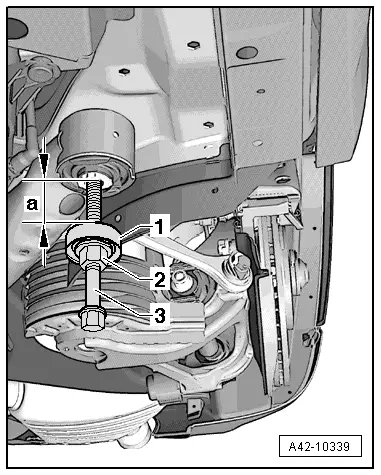

| Lower the subframe at each end separately. This avoids the need for checking and adjusting wheel alignment. |

| t

| Do not lower the subframe more than 4 cm. |

| t

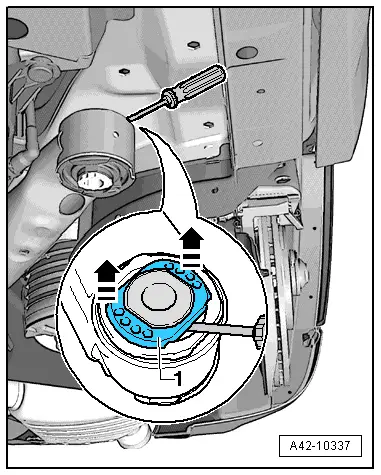

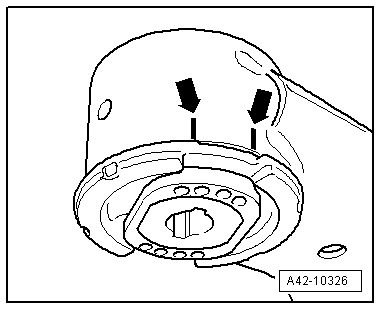

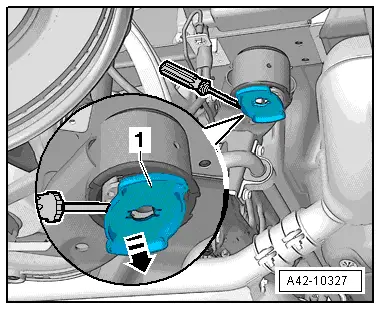

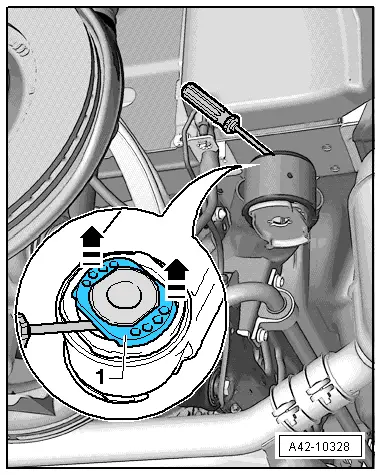

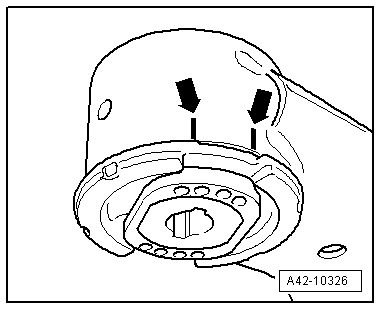

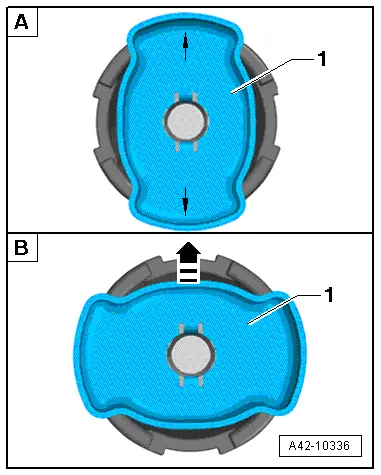

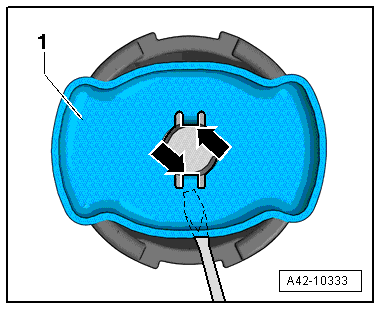

| Mark the position of the bonded rubber bushes in relation to the subframe before removing them. |

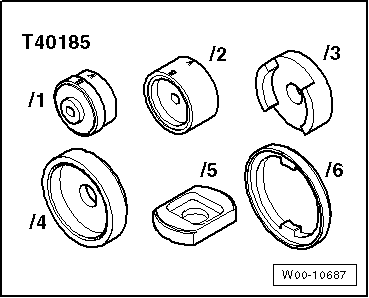

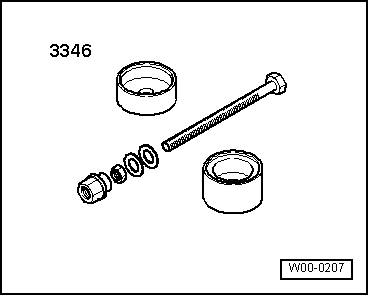

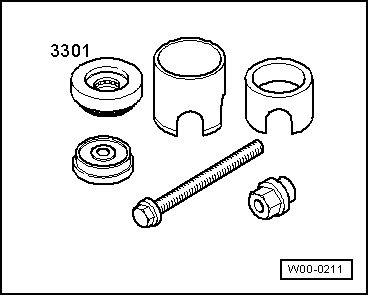

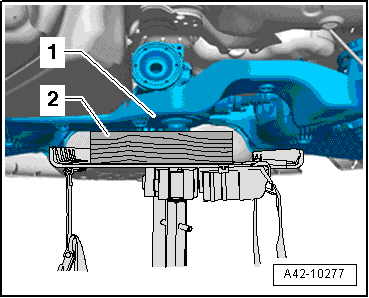

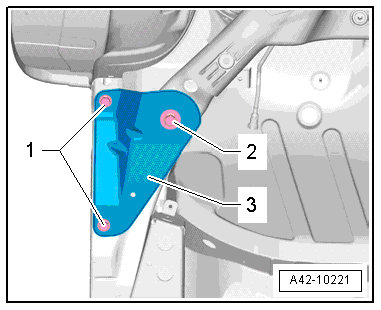

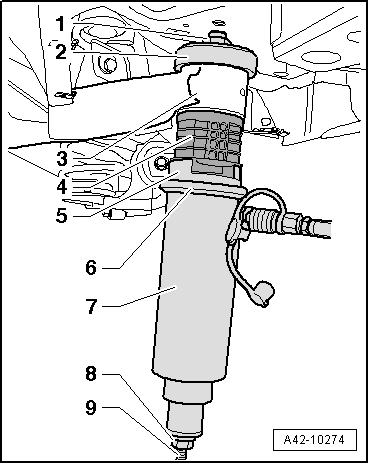

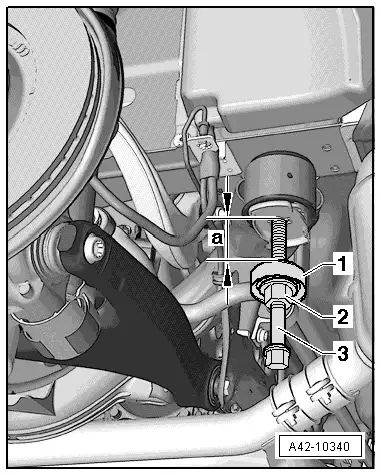

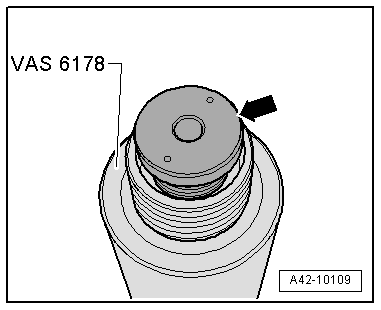

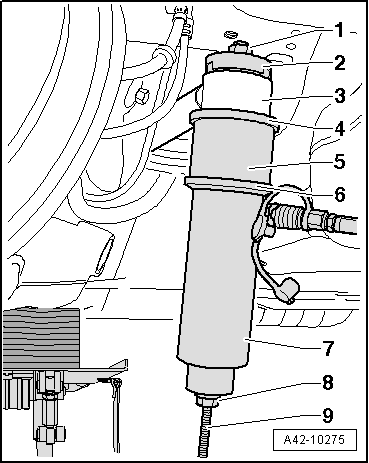

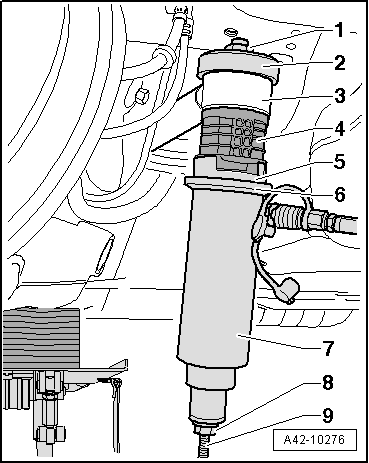

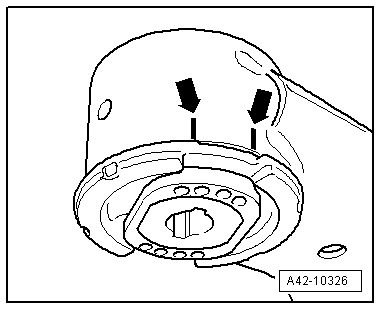

| Renewing conventional or hydraulic bonded rubber bush (front) |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING