A4 Mk3

|

Note

Note| t | Renew seals. |

| t | Do not re-use hydraulic fluid which has been drained off. |

| t | Use only hydraulic fluid. |

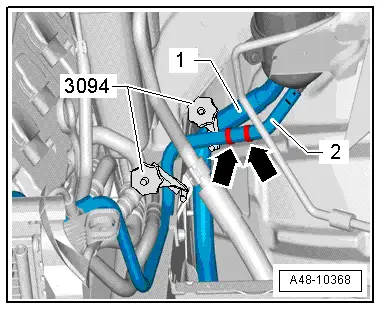

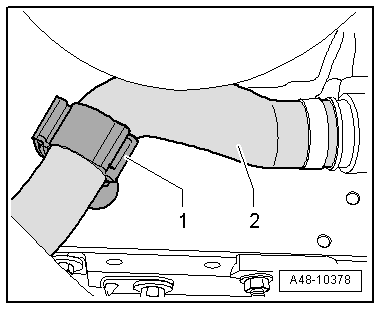

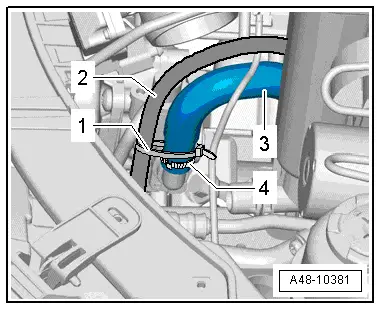

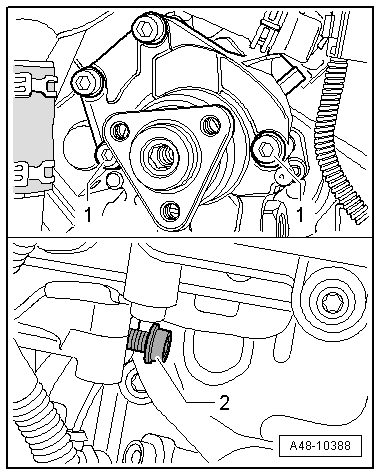

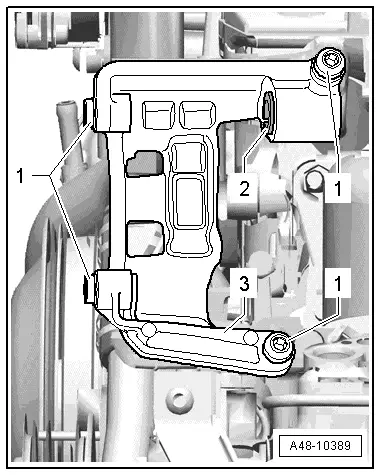

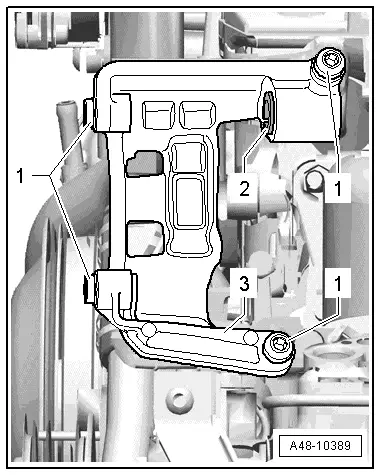

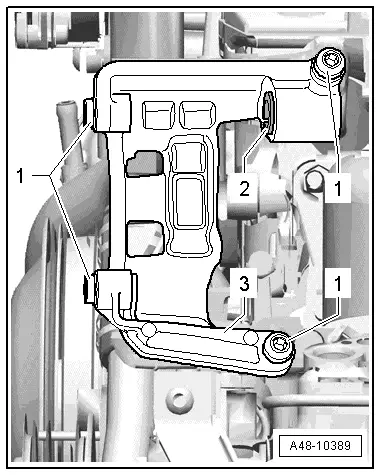

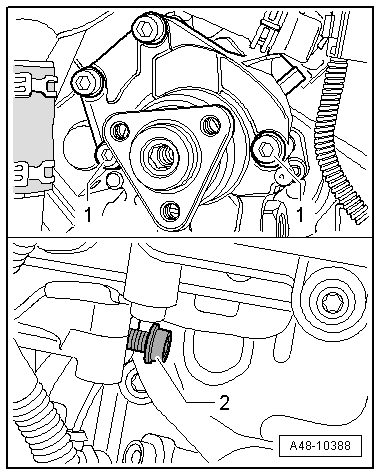

| 1 - | Bracket |

| 2 - | Sleeve |

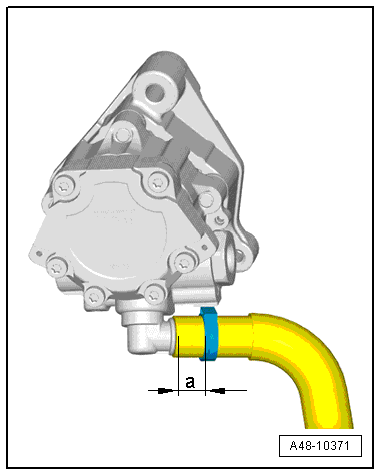

| q | Sleeve must be driven back slightly to install power steering pump |

| 3 - | Bolt |

| q | 20 Nm |

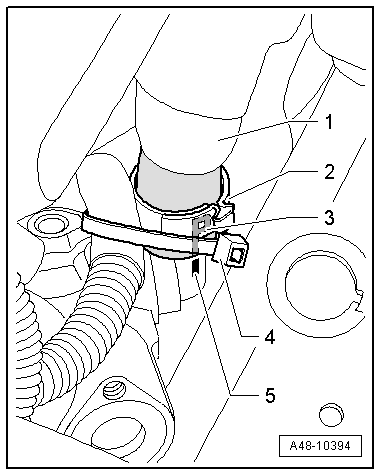

| 4 - | Hose clip |

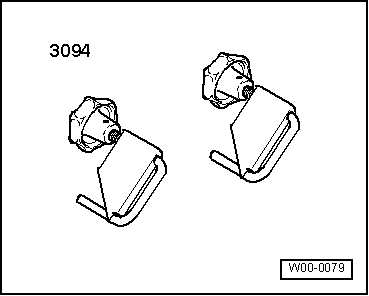

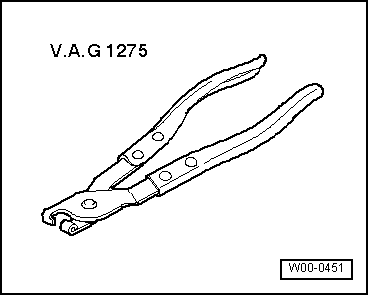

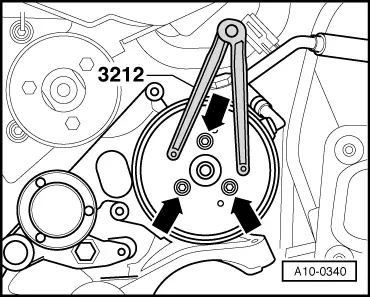

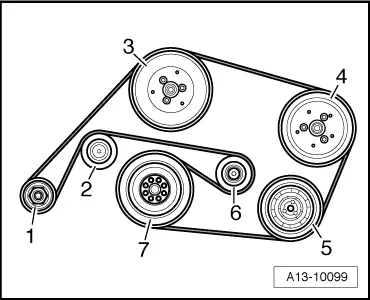

| q | Tighten using hose clip pliers -V.A.G 1275- |

| q | Always renew if removed |

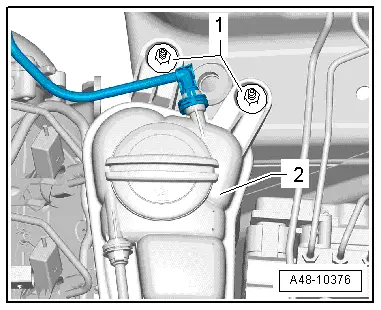

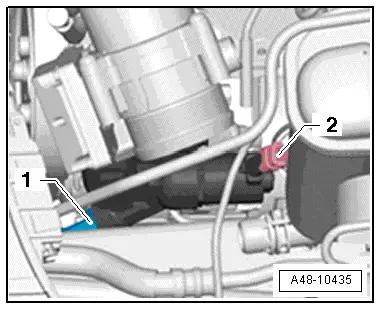

| 5 - | Suction hose |

| q | Marking „P“-arrow- on suction hose must be in line with seam -arrow- on power steering pump. |

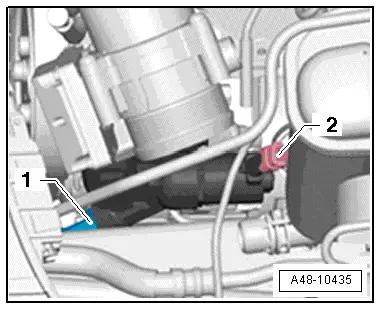

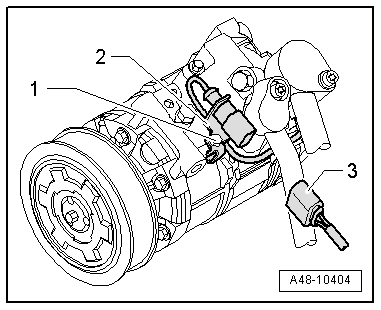

| 6 - | Regulating valve for power steering pump -(V119)- |

| q | Power steering pump and regulating valve are combined as one component and can only be renewed together |

| 7 - | Steering hydraulics pump -V119- |

| q | With regulating valve for power steering pump -(V119)- |

| q | Power steering pump and regulating valve → Item are combined as one component and can only be renewed together |

| q | For correct version refer to → Electronic parts catalogue |

| q | Fill with hydraulic fluid before installing |

| q | Checking delivery pressure → Chapter |

| q | Bleeding steering system → Chapter |

| q | Checking hydraulic fluid level → Chapter |

| q | Checking steering system for leaks → Chapter |

| 8 - | Seal |

| q | Always renew if removed |

| 9 - | Union nut |

| q | 38 Nm |

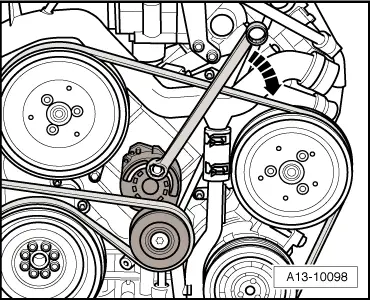

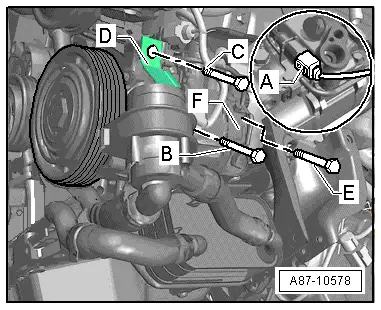

| 10 - | Pressure line |

Caution

Caution

|

| q | Note correct position: Angle between pipe connection and shaft of power steering pump is approx. 59° |

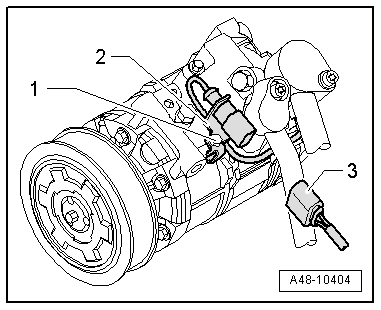

| q | Also secured to A/C compressor, depending on version |

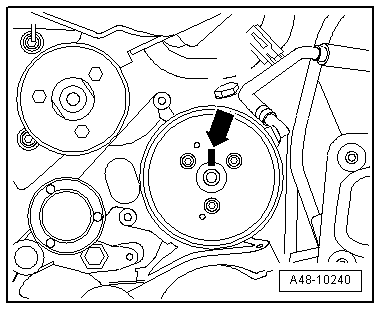

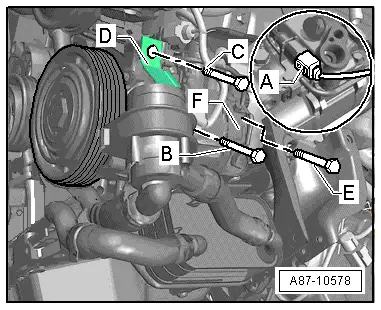

| 11 - | Bolt |

| q | 22 Nm |

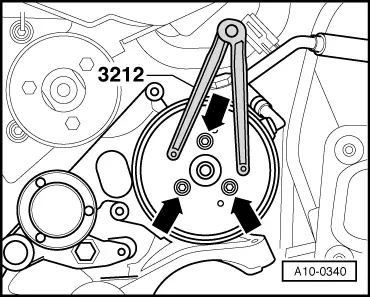

| 12 - | Belt pulley |

| 13 - | Bolt |

| q | 20 Nm |

| q | For securing bracket to engine |

| q | Note different lengths of bolts |

| 14 - | Bolt |

| q | 20 Nm |

| q | For securing bracket to engine |

| q | Note different lengths of bolts |

| 15 - | Bolt |

| q | 20 Nm |

| q | For securing power steering pump to bracket |

| 16 - | Bolt |

| q | 20 Nm |

| q | For securing bracket to engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|