A5

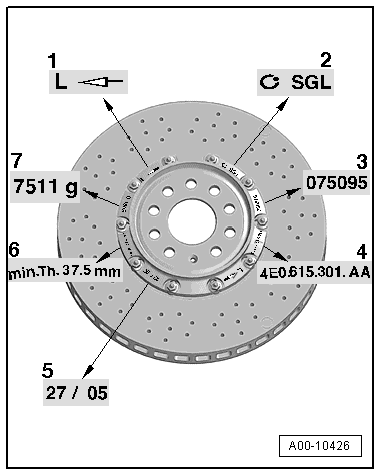

| 1 - | Direction of rotation |

| 2 - | Supplier |

| 3 - | Serial production number of brake disc |

| 4 - | Audi part number |

Note

Note| The Audi part number of the brake disc is an example and can vary depending on the vehicle type and model |

| 5 - | Production date of brake disc |

| 6 - | Permissible minimum thickness of brake disc |

Note

Note| The minimum permissible thickness of the brake disc differs depending on the type of vehicle. |

| 7 - | Weight of new brake disc with brake disc hub |

| Checking area of bolted connection on friction ring and brake disc hub: |

WARNING

WARNING

|

Note

Note| The weight of the new brake disc with hub differs depending on the type of vehicle. |

Note

Note

|

| 1. Wear assessment by checking thickness of brake disc → Chapter | |||

| Thickness of brake discs in permissible range → brake disc OK | |||

| Brake disc thickness in critical range min. Th + 0.2 mm | Value at or below limit | ||

| ↓↓ | ↓↓ | ||

| Further wear assessment on basis of wear indicators | Renew brake disc | ||

| ↓↓ | ---------- | ||

| 3. Wear assessment on basis of wear indicators → Chapter | |||

| None of the six wear indicators fully worn out → brake disc OK | |||

| ---------- | One of the six wear indicators fully worn out | ||

| --------- | ↓↓ | ||

| ---------- | Renew brake disc | ||

|

Caution

Caution