| –

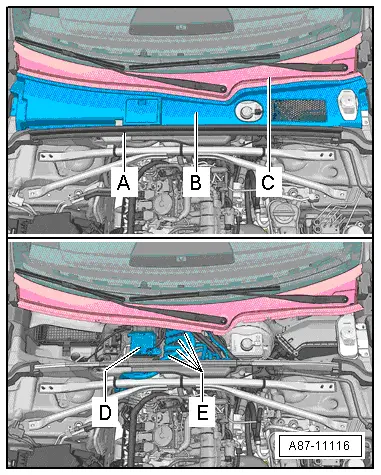

| Check for proper installation of the power and control electronics for electric drive -JX1--D- and the corresponding wiring -D- → Electrical system; Rep. gr.93 |

| Re-activation of high-voltage system |

DANGER! | Potentially fatal high voltage |

| Risk of fatal or serious injury from electric shocks |

| t

| High voltage at high-voltage system! |

| t

| For safety reasons, work on the high-voltage system is not to be performed by persons wearing electronic/medical life and health-preserving devices in or on the body. Life and health-preserving devices include internal painkiller pumps, implanted defibrillators, pacemakers, insulin pumps and hearing aids. |

| t

| The high-voltage system is only to be re-activated by an appropriately qualified person (Audi high-voltage engineer). |

| t

| Re-activation is to be determined solely by way of the Vehicle diagnostic tester employing the „Guided fault-finding“ routine. |

| t

| The qualified person (Audi high-voltage engineer) re-activates the vehicle. |

| t

| The qualified person (Audi high-voltage engineer) attaches signs to mark the vehicle accordingly. |

|

Note | t

| High-voltage system re-activation: |

| t

| Connect the vehicle diagnostic tester |

| t

| Select Guided fault-finding mode |

| t

| Use the Go to key to consecutively select the following menu items |

| t

| Function/component list |

| t

| Systems with self-diagnosis capability |

| t

| 8C - Hybrid battery management -J840 |

| t

| 8C - Hybrid battery management, functions |

| t

| 51 - Re-activation of high-voltage system (Rep. Gr. 93) |

| Vehicles with no high-voltage system |

| –

| Switch on the ignition. |

Note | t

| During basic setting, control motor assignment and adaption are implemented on the basis of the arrangement in the series connection of the wiring. If the sequence is not as specified, the matching of the control motors and thus flap control will not be correct → Chapter (block diagram of air conditioner control motors). |

| –

| Switch on the ignition. |

| –

| By making different settings on the air conditioner operating and display unit, Climatronic control unit -J255-, direct the air to the various vents and check whether the flow of air out of the vent actually changes in line with the setting. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution DANGER!

DANGER!