| –

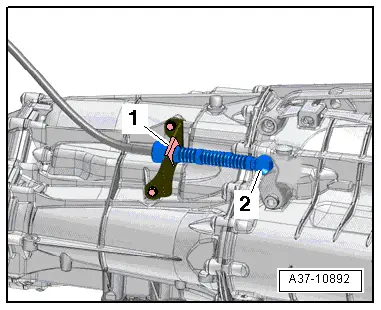

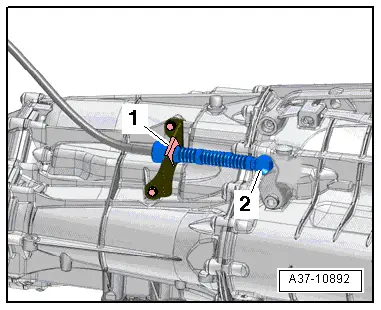

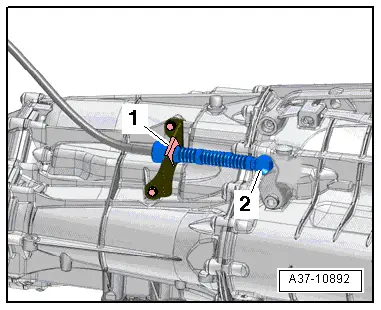

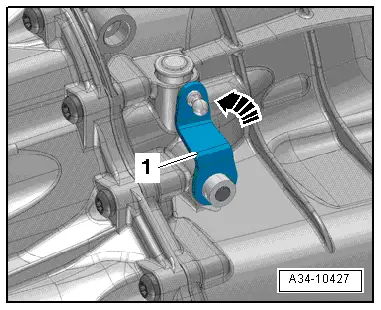

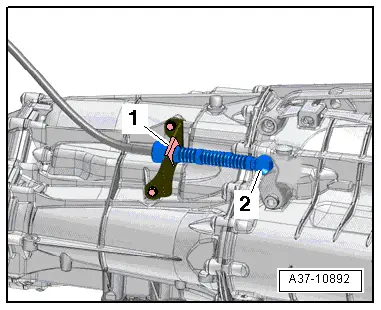

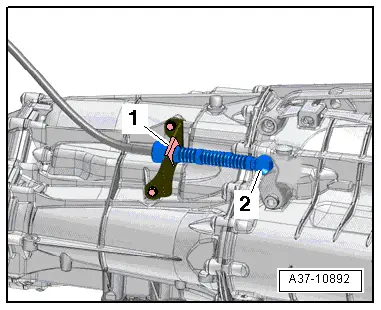

| Carefully press ball socket -2- of selector lever cable onto gearbox selector lever in this position. |

Note | t

| Take care not to bend gearbox selector lever when pressing on cable; support lever if necessary, as otherwise selector mechanism can no longer be adjusted accurately. |

| t

| -Item 1- can be disregarded. |

| –

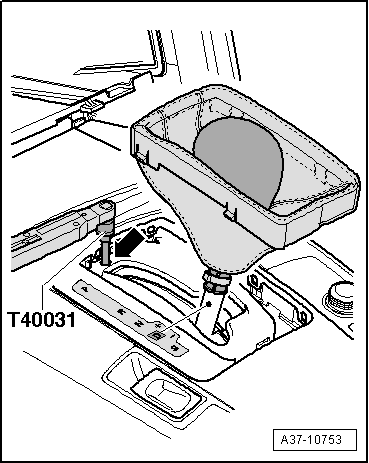

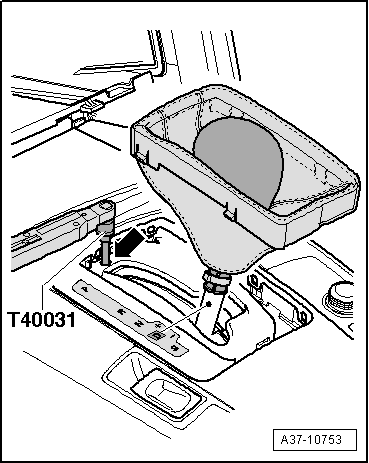

| With vehicle diagnostic tester in Guided Fault Finding mode, select 02 - Gearbox electronics and the function 02 - Measured values. |

| –

| Select the value for Gear from the menu. |

| –

| Compare the following readings: |

| t

| Value for Gear on vehicle diagnostic tester |

| t

| Selector lever position |

| t

| Gear indicated on selector lever position display -Y26- (on selector mechanism) |

| t

| Selector lever position display -Y6- in instrument cluster |

| l

| The displays should match |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note