| –

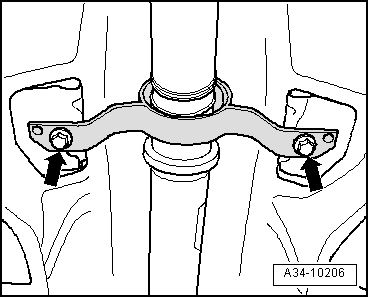

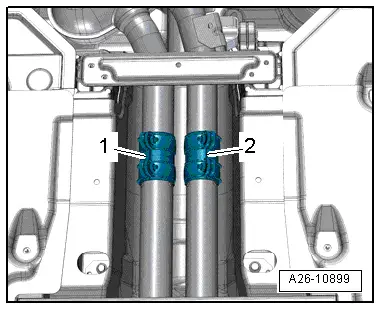

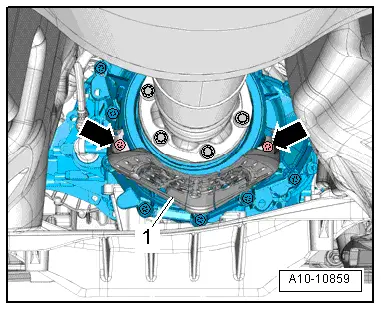

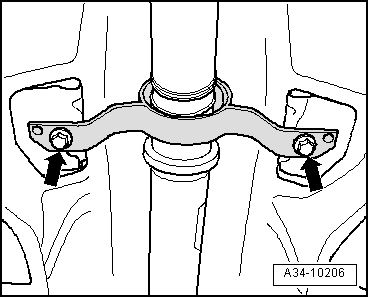

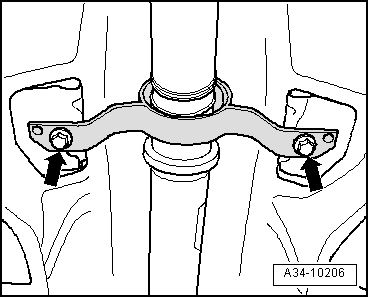

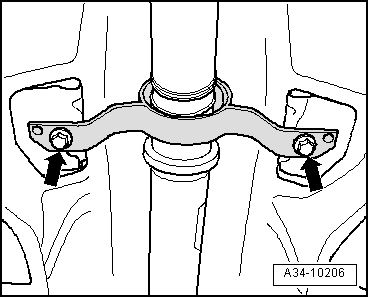

| Remove bolts -arrows- securing centre propshaft bearing. |

| –

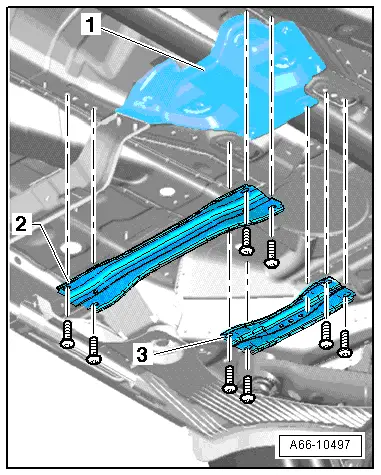

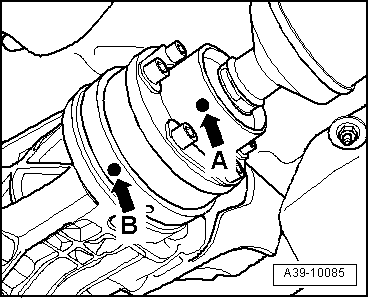

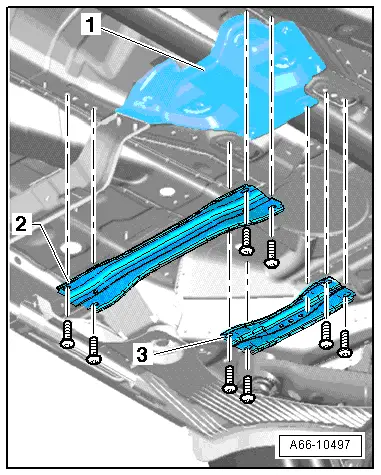

| Guide propshaft downwards at rear, past fuel tank and rear subframe, and detach from gearbox. |

Note | t

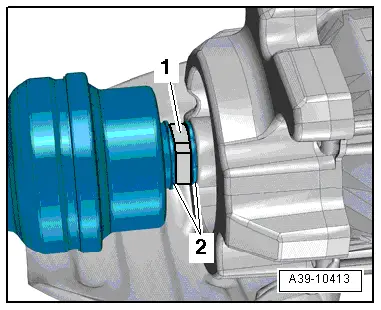

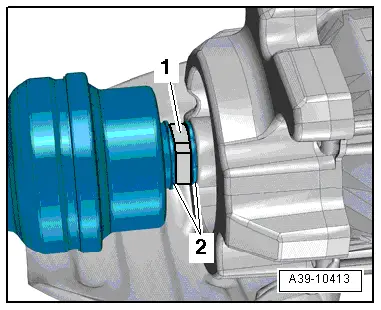

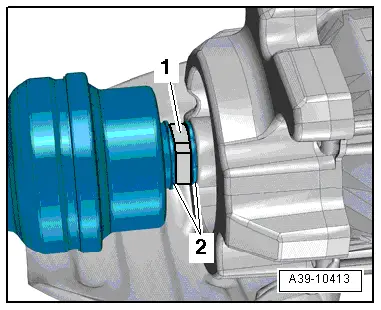

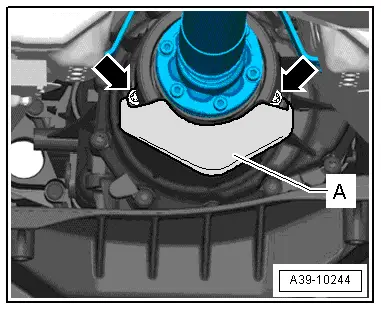

| Remove old, dried-out high-temperature grease from CV joint and flange for propshaft. Put in exactly the same quantity of fresh high-temperature grease -G 000 633-. |

| t

| Clean remaining locking fluid out of tapped holes in flange shaft on rear final drive. The threads can be cleaned with a thread tap. Otherwise the securing bolts can shear off when they are screwed in. |

| t

| Renew self-locking bolts for propshaft. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution