A5

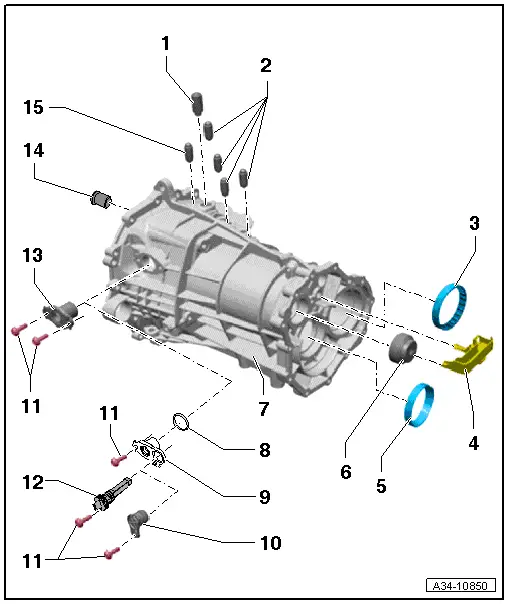

| Exploded view - servicing gearbox cover |

| Special tools and workshop equipment required |

| t | Crankshaft seal installing tool -VW 204 B- |

| t | Drift -VW 207 C- |

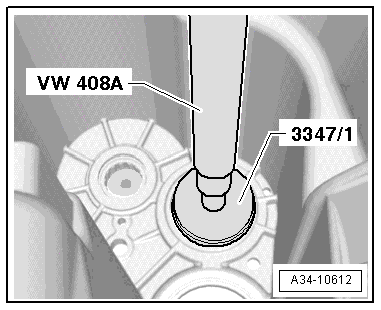

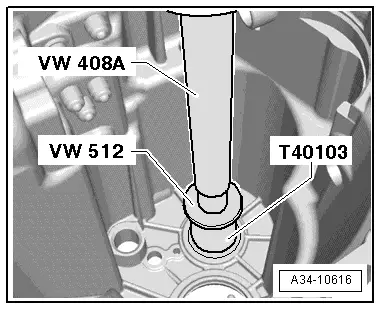

| t | Press tool -VW 408 A- |

| t | Press tool -VW 411- |

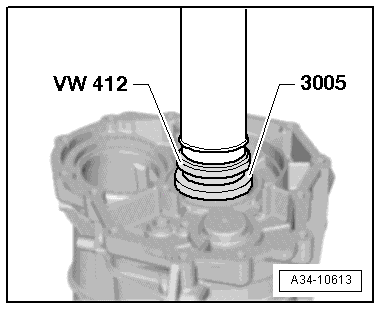

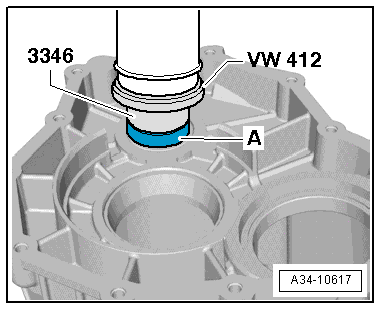

| t | Press tool -VW 412- |

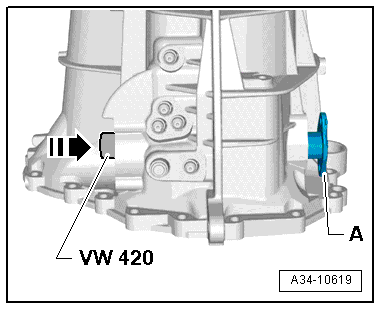

| t | Tube -VW 420- |

| t | Tube -VW 423- |

| t | Thrust piece -VW 434- |

| t | Sleeve -VW 472/2- |

| t | Thrust pad -VW 512- |

| t | Guide pin -10 - 15- |

| t | Press tool -40 - 21- |

| t | Thrust plate -3005- |

| t | Drift -3138- |

| t | Extension -3161- |

| t | Assembly tool -3346- |

| t | Assembly tool -3347- |

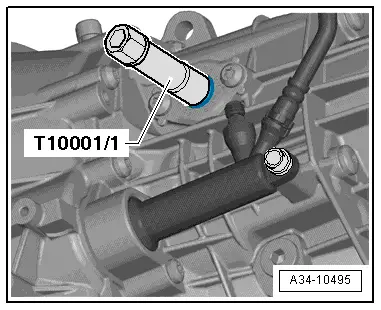

| t | Shock absorber set -T10001- |

|

|

|

|

|

|

|

|

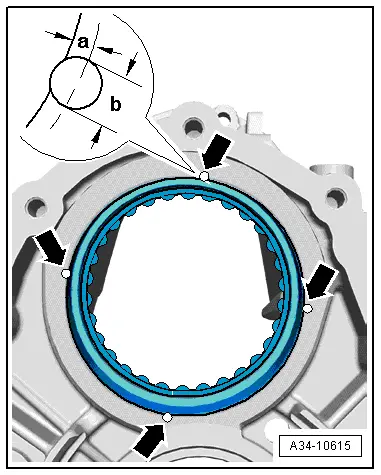

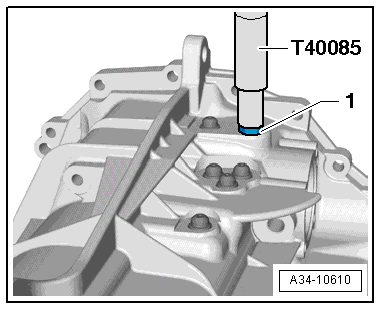

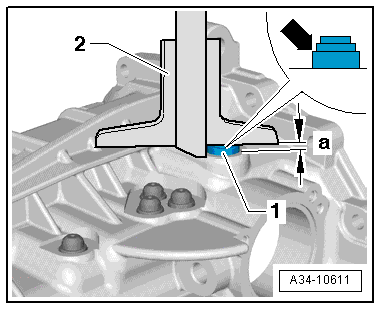

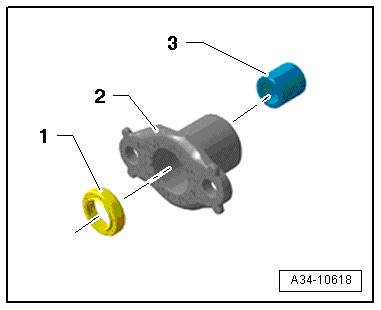

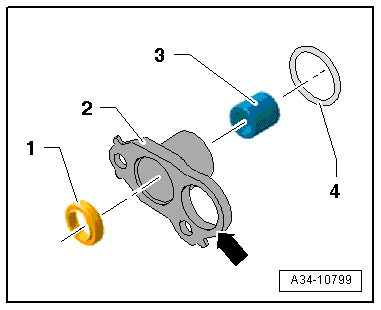

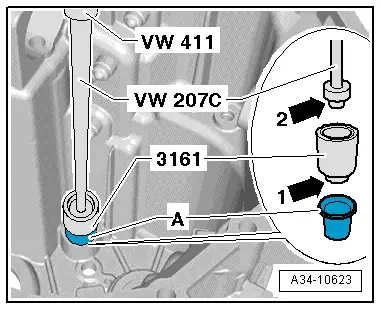

| 1 - | Large locking bush |

| q | For selector shaft |

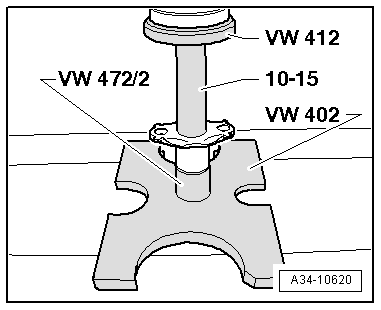

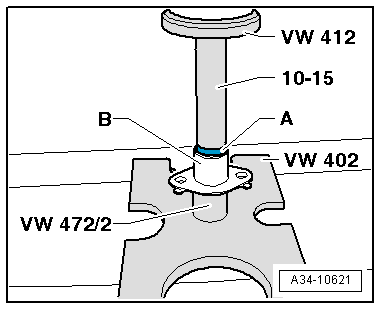

| q | Removing and installing → Fig. |

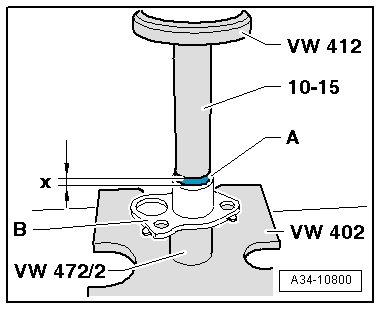

| q | Installation depth → Fig. |

| 2 - | Locking bush |

| q | For selector plate / selector fork |

| q | At present there is no provision for removing and installing |

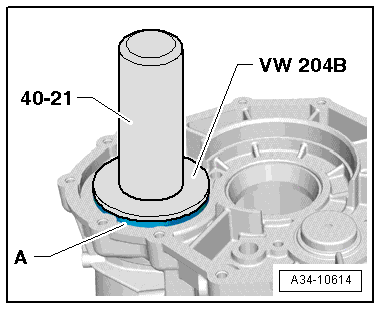

| 3 - | Needle bearing |

| q | Bearing for side shaft |

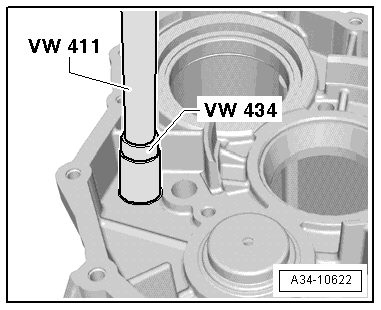

| q | Drive out of gearbox cover using drift -3138- |

| q | Always renew |

| q | Driving in → Fig. |

| q | Peen to secure after installing → Fig. |

| 4 - | Oil collector |

| q | Fit in holes in gearbox cover and roller bearing → Item |

| 5 - | Tapered roller bearing outer race |

| q | Bearing for spur gear in gearbox cover |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 6 - | Roller bearing |

| q | Bearing for input shaft |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 7 - | Gearbox cover |

| 8 - | O-ring |

| q | Only installed in gearboxes with sealing cap/selector shaft in conjunction with gearbox neutral position sender -G701- or sealing plug |

| q | Always renew |

| 9 - | Sealing cap |

| q | For selector shaft in conjunction with gearbox neutral position sender -G701- or sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Exploded view → Fig. |

| q | Removing and installing oil seal for selector shaft → Fig. |

| q | Removing ball sleeve for selector shaft → Fig. |

| q | Installing ball sleeve for selector shaft → Fig. |

| 10 - | Sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Renew O-ring on sealing plug; select correct version according to gearbox code letters → Electronic parts catalogue |

| 11 - | Bolt |

| q | 10 Nm and then turn 45° further |

| q | Aluminium bolts (M8; 22 mm long) |

| q | Always renew |

| 12 - | Gearbox neutral position sender -G701- |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Renew O-ring on gearbox neutral position sender -G701-; select correct version according to gearbox code letters → Electronic parts catalogue |

| 13 - | Sealing cap |

| q | For selector shaft without gearbox neutral position sender -G701- or sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Removing and installing → Fig. |

| q | Exploded view → Fig. |

| q | Removing and installing oil seal for selector shaft → Fig. |

| q | Removing ball sleeve for selector shaft → Fig. |

| q | Installing ball sleeve for selector shaft → Fig. |

| 14 - | Bearing bush |

| q | For 3rd/4th gear selector plate / selector fork |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 15 - | Small locking bush |

| q | For selector shaft |

| q | At present there is no provision for removing and installing |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|