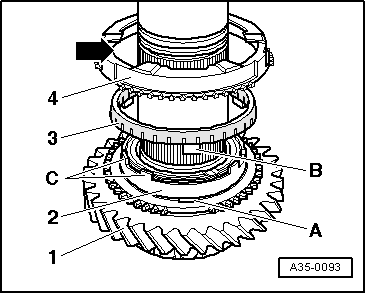

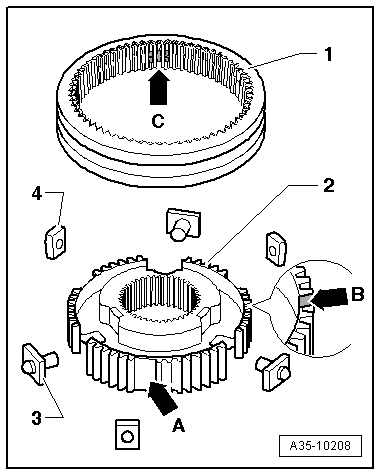

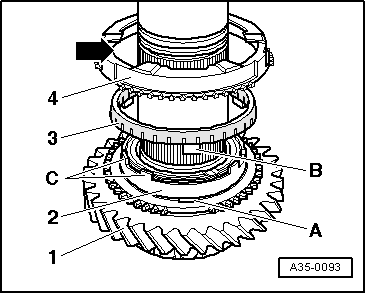

| Installation position of synchro-rings for 3rd to 6th gear |

Note | If components are not being renewed, make sure they are re-installed on the same gear. |

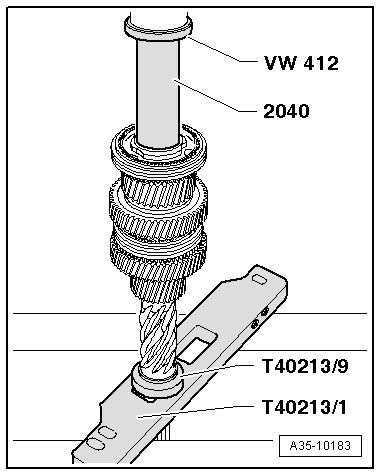

| –

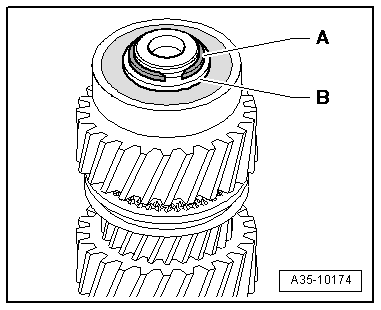

| Fit inner ring -2- onto selector gear -1-. |

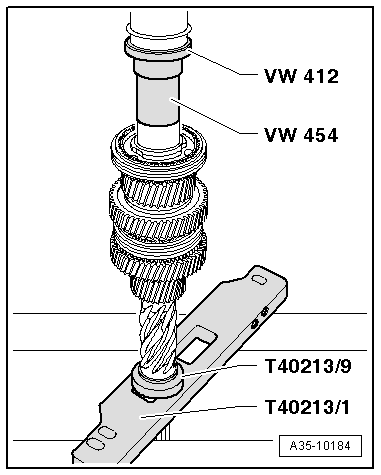

| –

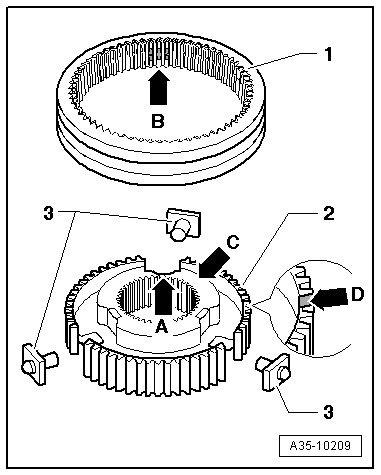

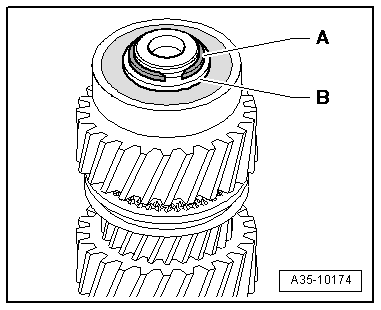

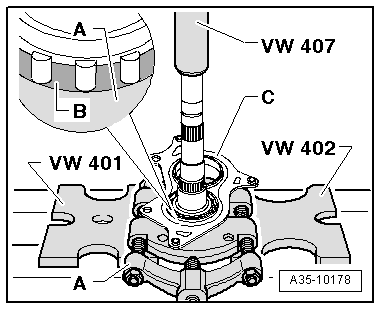

| Fit intermediate ring -3-. Lug -B- must be inserted into recess -A-. |

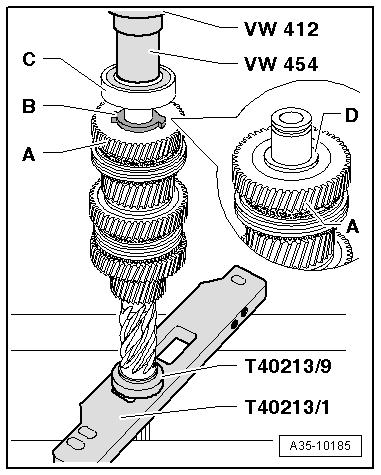

| –

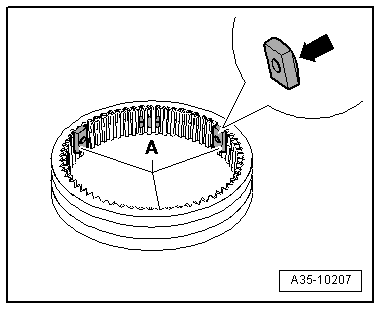

| Fit synchro-ring -4-. Guide lugs -C- through recess -arrow-. |

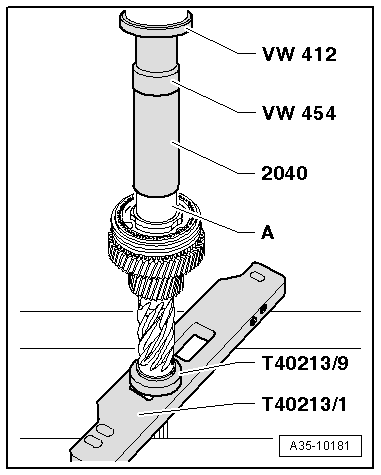

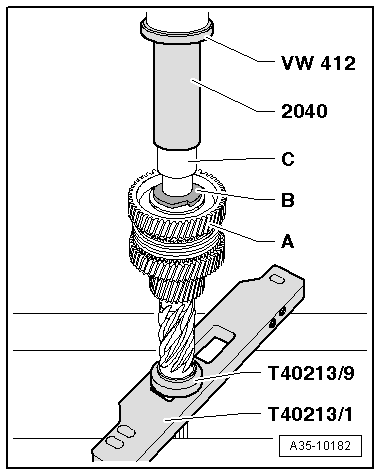

| Note the following when performing the following steps: |

| –

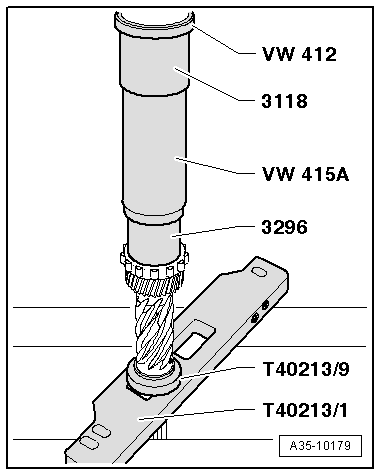

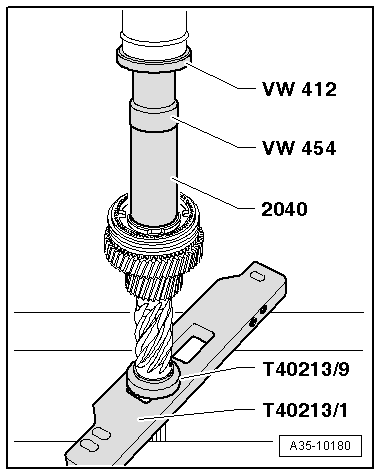

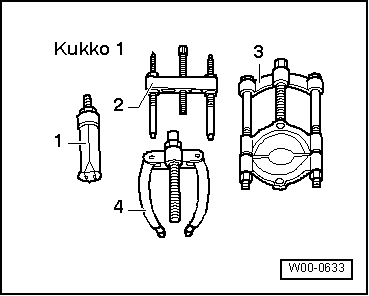

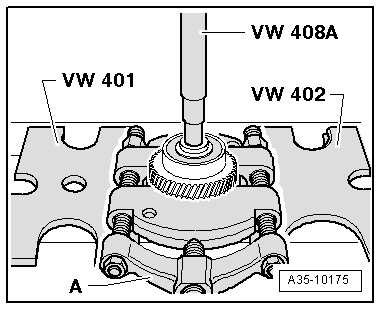

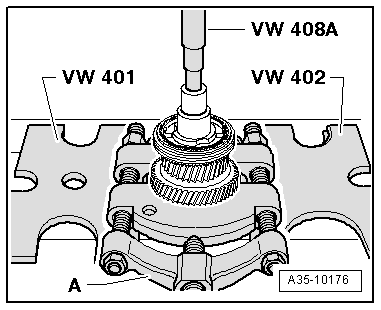

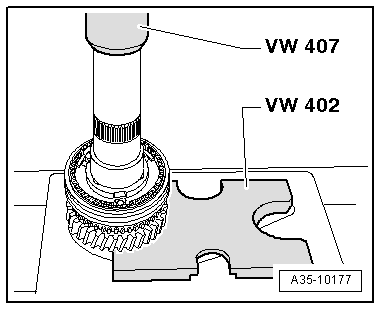

| Position drift sleeves on centre of heated components (synchronising hub and needle bearing inner races). |

| –

| First press on components just briefly, then stop exerting pressure and check whether drift sleeves are still positioned properly and press on as far as stop. |

| When pressing on, lugs on synchro-rings must line up with recesses in synchronising hub. To do so, lift corresponding selector gear with synchro-rings slightly so that it engages in the slots in the synchronising hub. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note