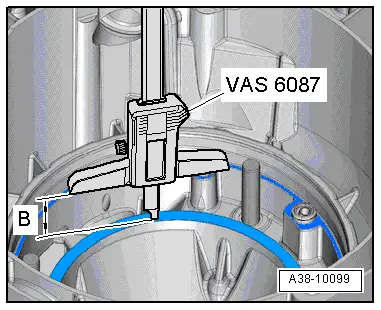

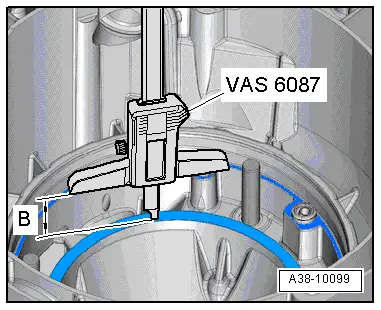

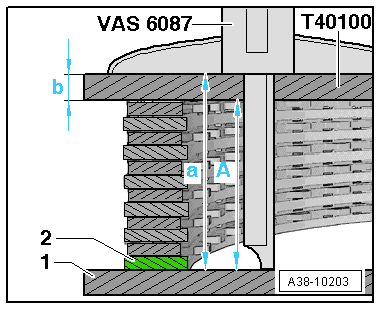

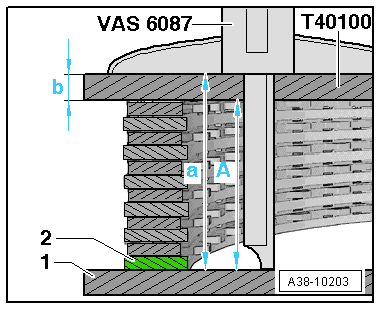

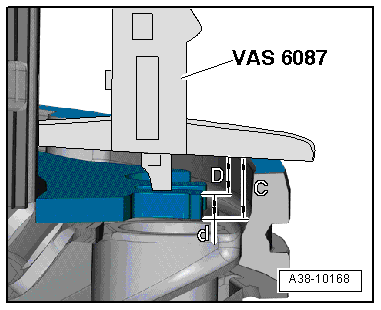

| 1. Calculating dimension -B-; measurement from contact surface of input shaft cover to contact surface of corrugated washer: |

| –

| Clean contact surfaces and sealing surfaces on gearbox housing. Completely remove any remaining sealing material. |

| –

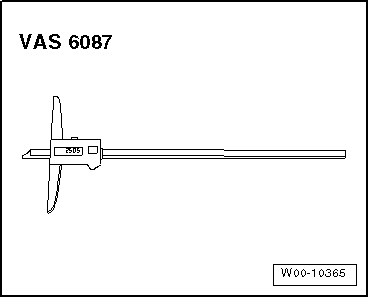

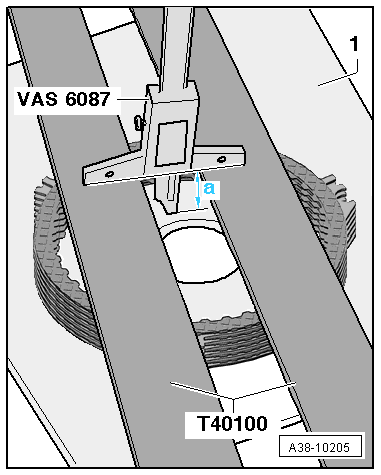

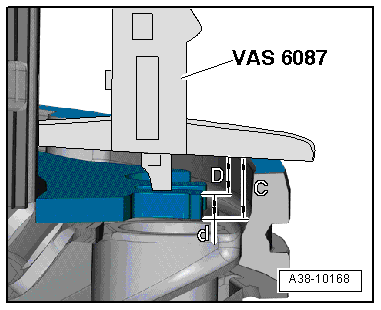

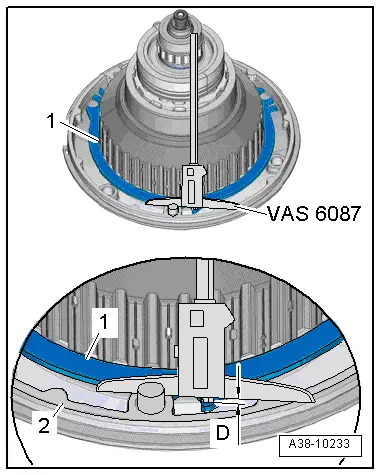

| Use digital depth gauge -VAS 6087- to measure from contact surface of input shaft cover to contact surface of corrugated washer in gearbox housing. |

| –

| Note down dimension „B1“. |

| –

| Repeat measurement at two other points on the circumference and note down dimensions „B2“ and „B3“. |

| –

| Calculate mean value -B- from the 3 measured values and note down. |

| Mean value: = dimension -B- |

| –

| Note down dimension -B-. |

| 29,0 mm + 28,9 mm + 29,0 mm | | 3 |

= 28.97 mm |

| In this example, dimension -B- = 28.97 mm. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note