A5

| Renewing valve stem oil seals with cylinder head installed |

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

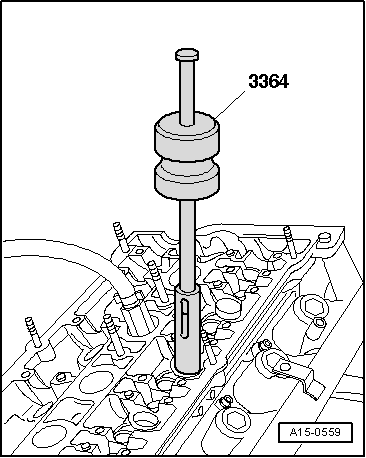

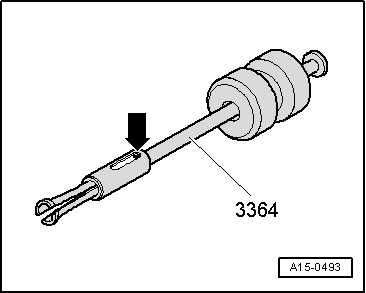

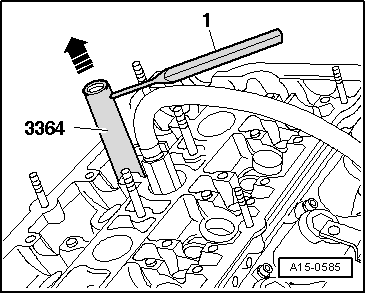

| t | Valve stem seal puller -3364- |

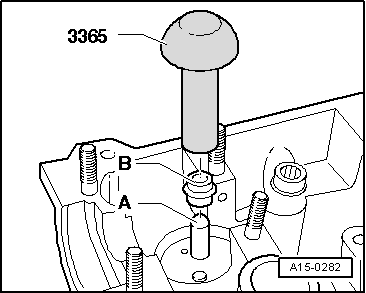

| t | Valve stem seal fitting tool -3365- |

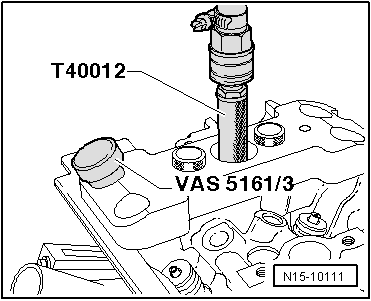

| t | Adapters -T40012- |

| t | Torque wrench -V.A.G 1331- |

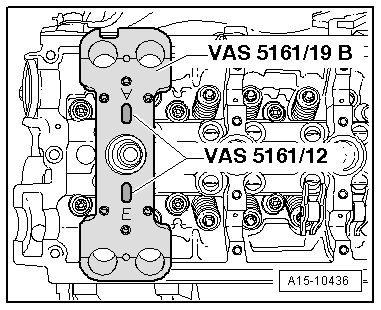

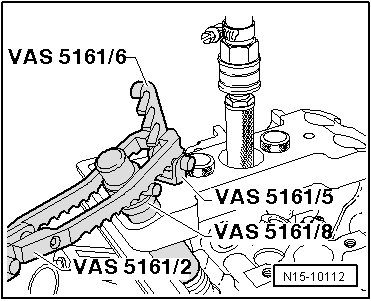

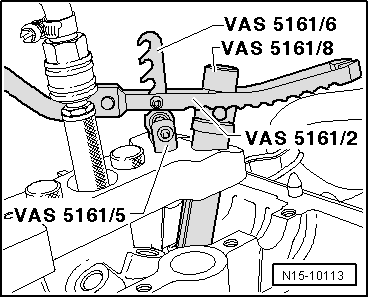

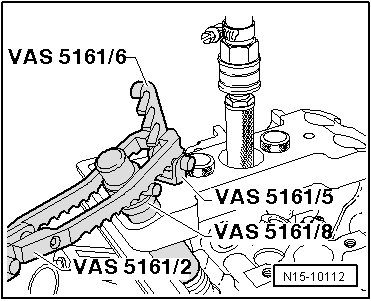

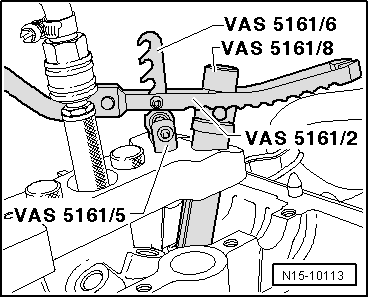

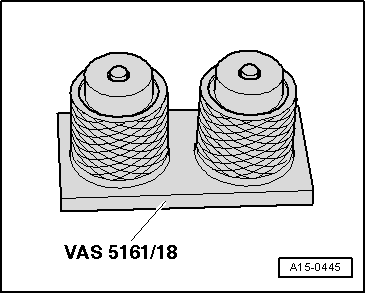

| t | Removal and installation device for valve cotters -VAS 5161- |

| t | Guide plate for 2.0 ltr. and 3.0 ltr. FSI engine -VAS 5161/19B- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|