A5

|

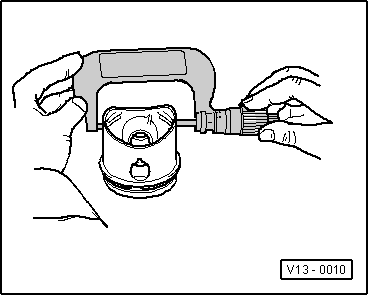

| Piston Ø | ||||

| Basic dimension | mm | 82.465 1) | ||

| ||||

|

|

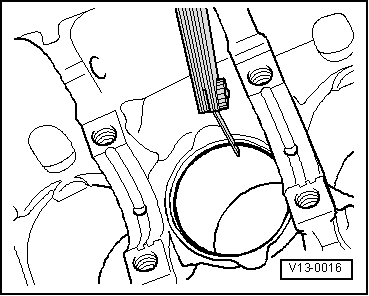

| Piston ring Dimensions in mm | New | Wear limit |

| Compression ring | 0.20...0.40 | 0.80 |

| Oil scraper ring | 0.25...0.50 | 0.80 |

|

|

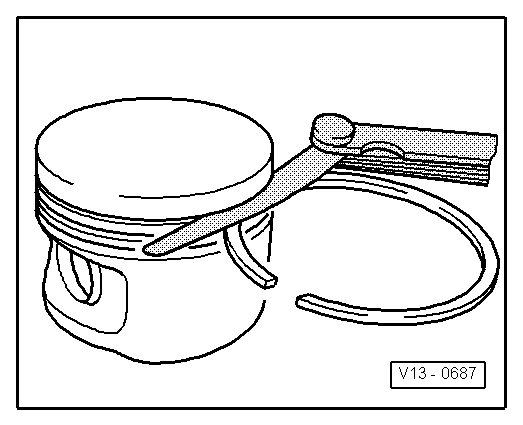

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.06 … 0.09 | 0.20 |

| 2nd compression ring | 0.03 … 0.06 | 0.15 |

| Oil scraper rings | Cannot be measured | |

|

|

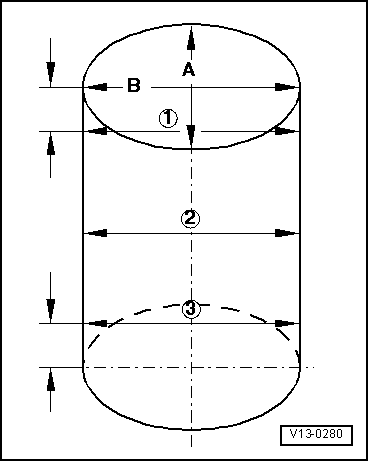

| Cylinder bore Ø | ||

| Basic dimension | mm | 82.51 |

Note

Note

|

Caution

Caution