| t

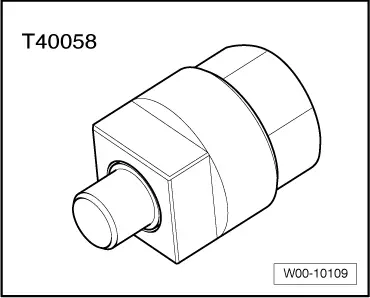

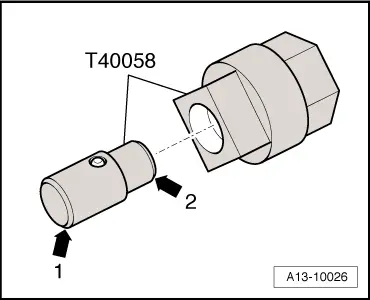

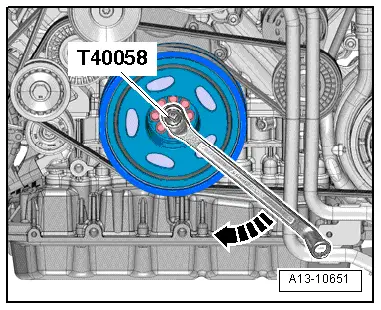

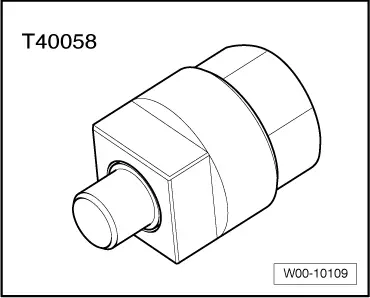

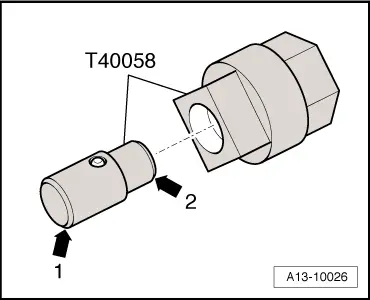

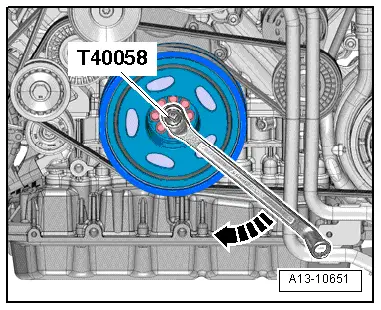

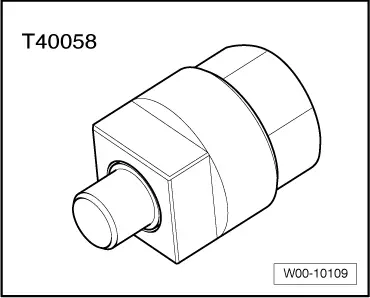

| Adapter -T40058- for vehicles with dual clutch gearbox 0B5 |

| –

| Start engine and run until radiator fan has started up once. |

| –

| Increase engine speed to approx. 2500 rpm for 2 minutes (perform road test if necessary). |

| –

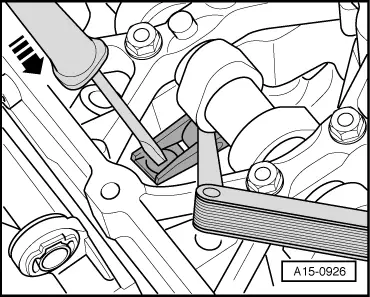

| If the compensation elements are still noisy, locate the defective compensation element as follows: |

| –

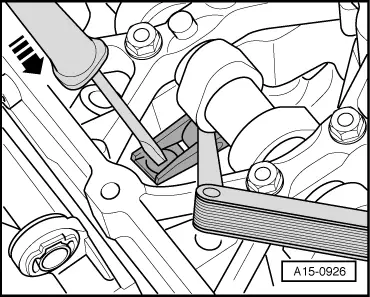

| Turn crankshaft until cam of hydraulic compensation element to be tested is at top: |

| Vehicles with manual gearbox: |

| –

| Push vehicle forwards with 4th gear engaged and ignition switched off. |

|

|

|