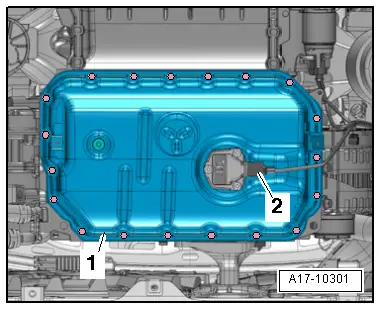

Removing and installing sump for 6-cylinder direct petrol injection engine

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note |

|

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING