A5

| Removing and installing camshaft timing chains |

| Special tools and workshop equipment required |

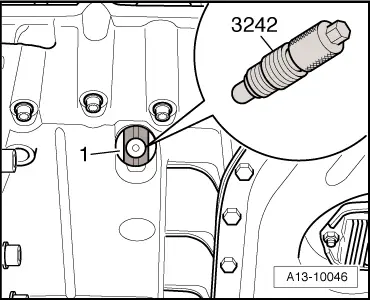

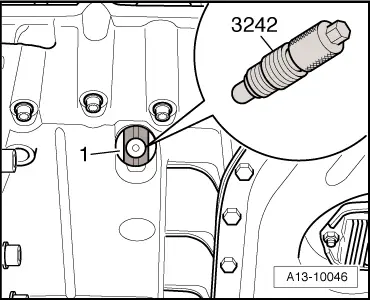

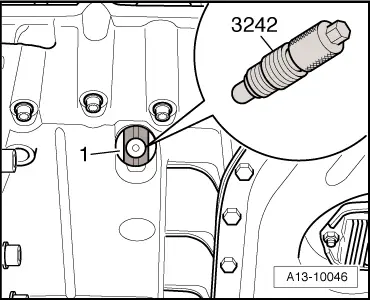

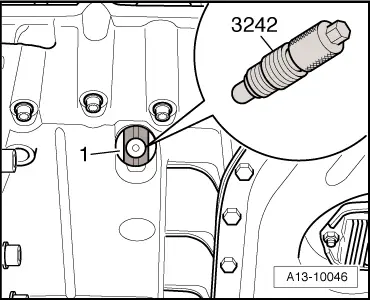

| t | Locking pin -3242- |

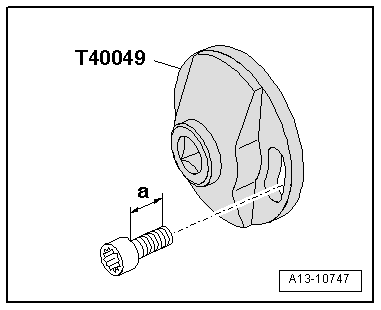

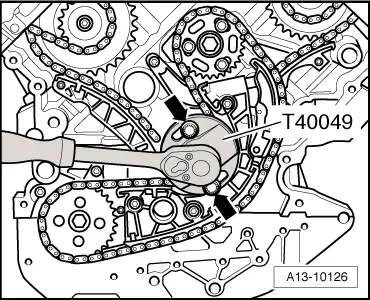

| t | Special wrench -T40049- |

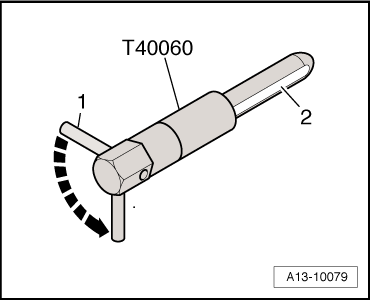

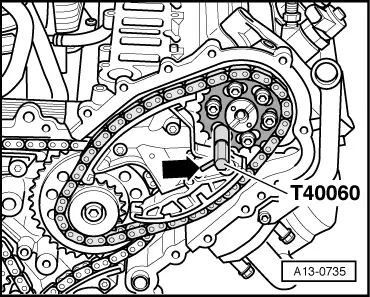

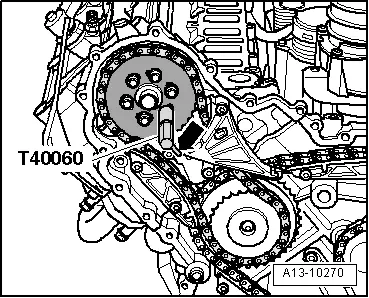

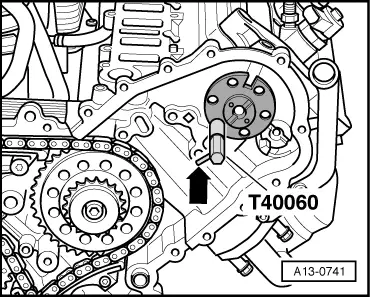

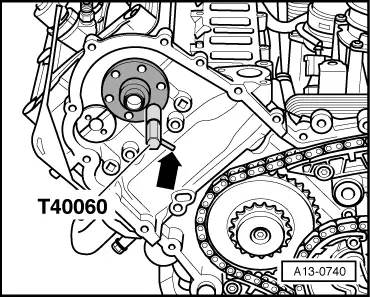

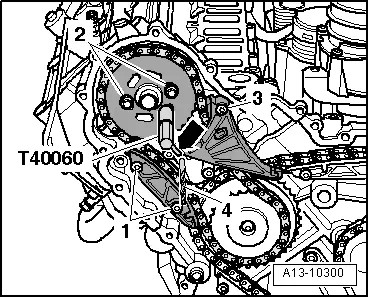

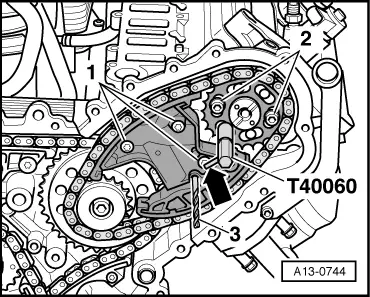

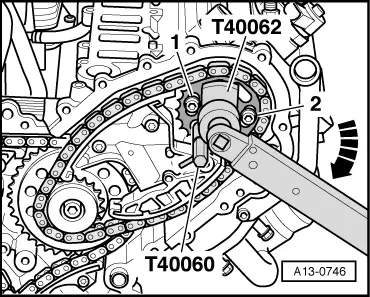

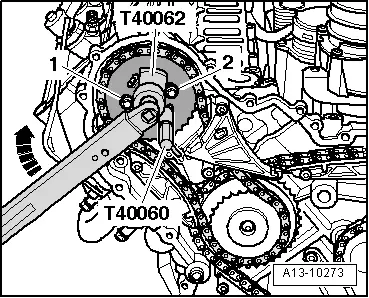

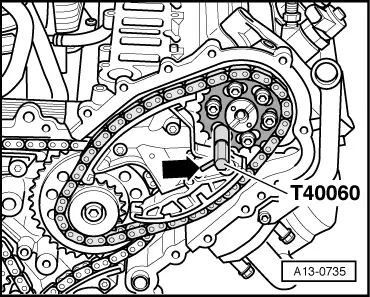

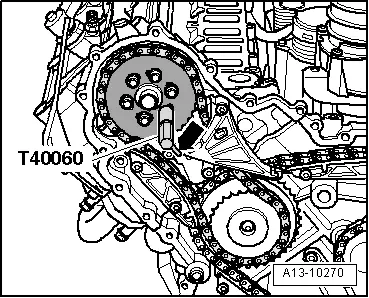

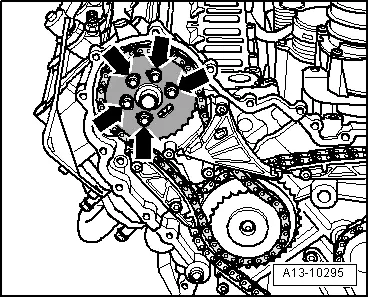

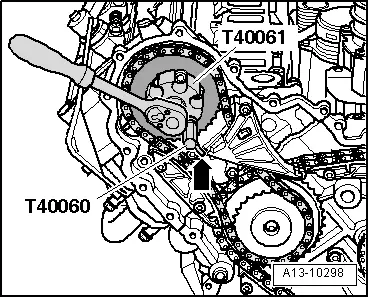

| t | 2x Adjustment pin -T40060- |

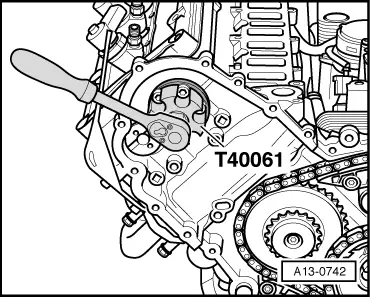

| t | Adapter -T40061- |

| t | Adapter -T40062- |

| t | Nuts M12 (2x) |

| t | Drill bit 3.3 mm Ø (2x) |

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution