A5

| Removing engine - vehicles with manual gearbox |

| Special tools and workshop equipment required |

| t | Removal lever -80 - 200- |

| t | Stepladder -VAS 5085- |

| t | Engine bung set -VAS 6122- |

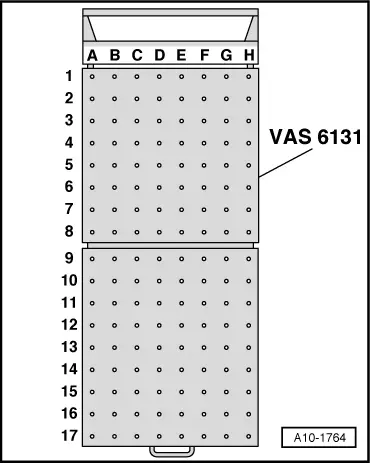

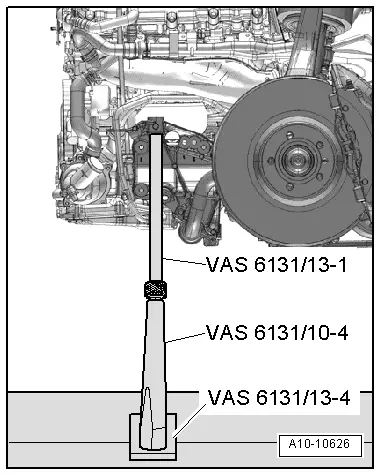

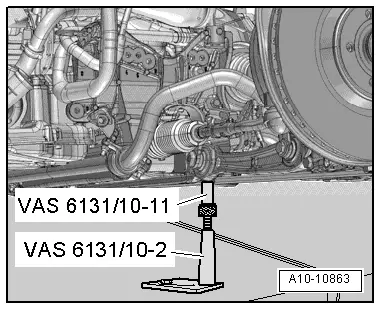

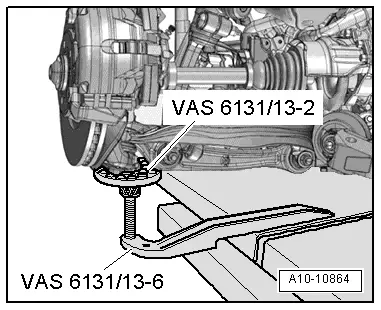

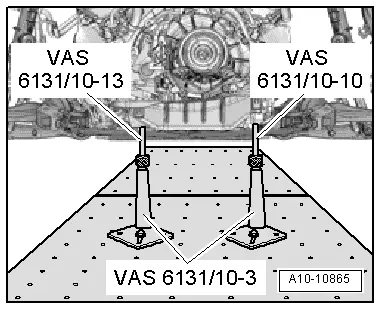

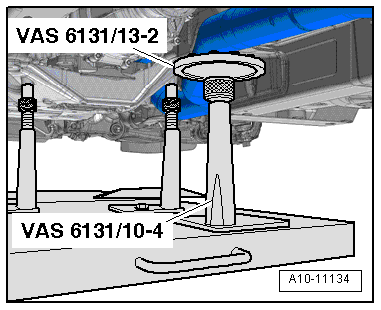

| t | Scissor-type assembly platform -VAS 6131 A- with support set for Audi -VAS 6131/10- and supplementary set -VAS 6131/13- |

| t | Drip tray for workshop hoist -VAS 6208- |

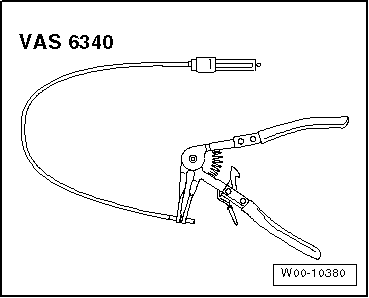

| t | Hose clip pliers -VAS 6362- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

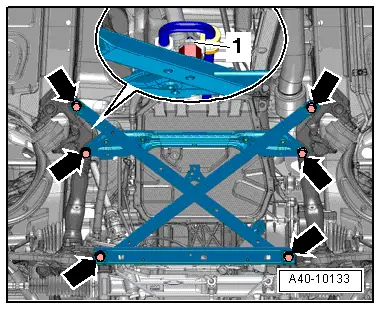

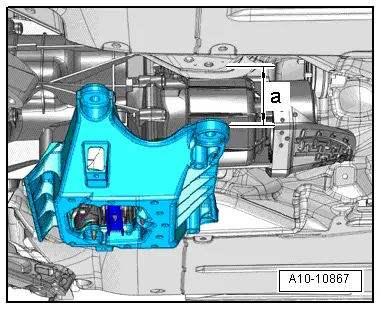

| Platform coordinates | Parts of support set for Audi -VAS 6131/10- and supplementary set -VAS 6131/13- | |||

| B4 | /13-4 | /10-4 | /10-5 | /13-1 |

| G4 | /13-4 | /10-4 | /10-5 | /13-1 |

| B6 | /10-1 | /10-2 | /10-5 | /10-11 |

| G6 | /10-1 | /10-2 | /10-5 | /10-11 |

| A8+C8 | /13-6 | – | – | /13-2 |

| F8+H8 | /13-6 | – | – | /13-2 |

| C14 | /10-1 | /10-3 | /10-5 | /10-13 |

| F14 | /10-1 | /10-3 | /10-5 | /10-10 |

| F17 | /10-1 | /10-4 | /10-5 | /13-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution