| Continuation for both sides: |

| –

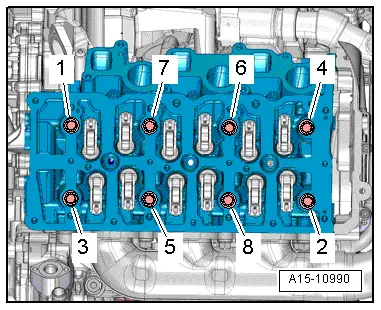

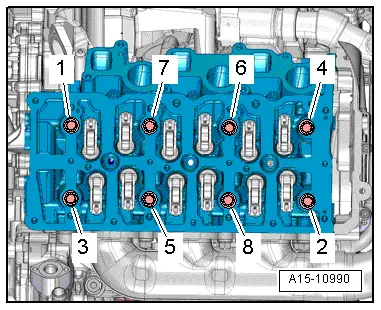

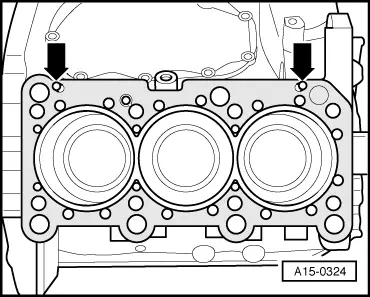

| Slacken cylinder head bolts in the sequence -1 ... 8-. |

| –

| Remove bolts and carefully take off cylinder head. |

Caution | Risk of damage to glow plugs when putting down cylinder head. |

| After removal, the cylinder head must not be put down on the gasket side with the glow plugs still installed, because the glow plugs project slightly beyond the gasket surface. |

|

| Installation is carried out in the reverse order; note the following: |

Caution | Avoid damage to sealing surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Risk of leaks at cylinder head gasket. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

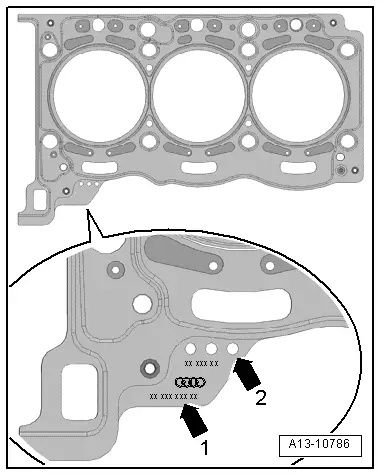

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| Renew self-locking nuts as well as seals, gaskets and O-rings. |

| t

| Cylinder heads must not be reworked on TDI engines. |

| t

| When installing an exchange cylinder head, the contact surfaces between roller rocker fingers and cams must be oiled before installing the cylinder head cover. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and the coolant in the entire cooling system. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution