| –

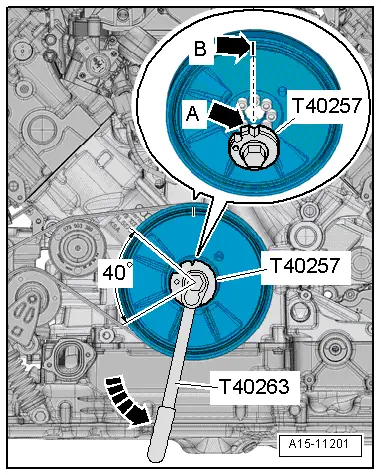

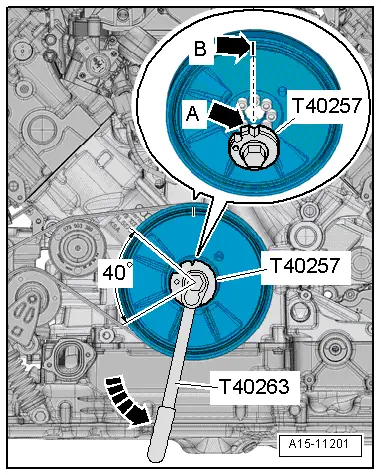

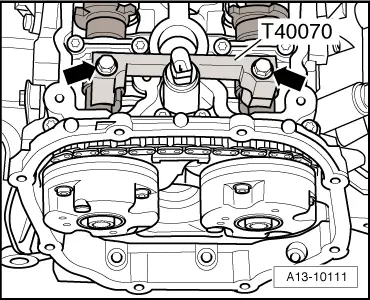

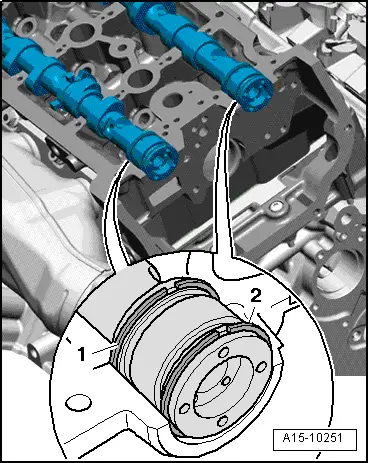

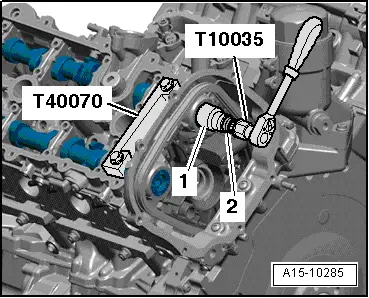

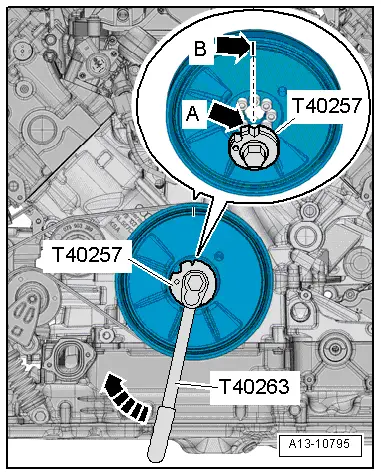

| Fit adapter -T40257- onto wrench -T40263-. |

| –

| Position adapter on bolts of vibration damper. |

| l

| Notch -arrow A- on adapter -T40257- must point to coloured line -arrow B- on vibration damper. |

Note | Semi-circular recess on adapter -T40257- can be disregarded. |

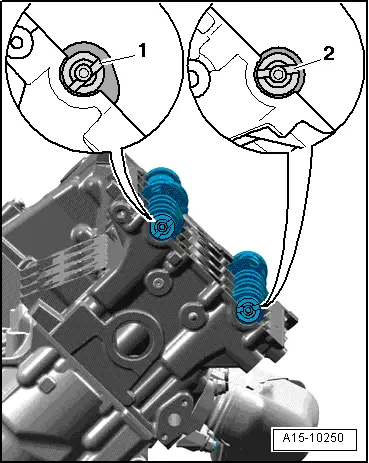

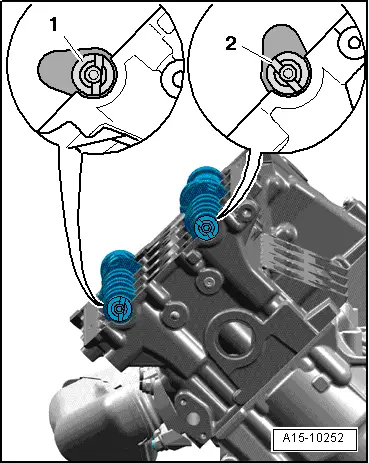

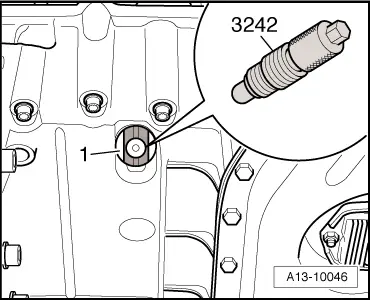

Caution | Avoid damage to valves and piston crowns. |

| When performing the following steps, the crankshaft must not be at „TDC“ position at any cylinder. |

|

| –

| Using counterhold tool -T10172- with -T10172/7-, turn crankshaft back through 40° out of „TDC“ position in opposite direction to normal rotation -arrow-. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING