| –

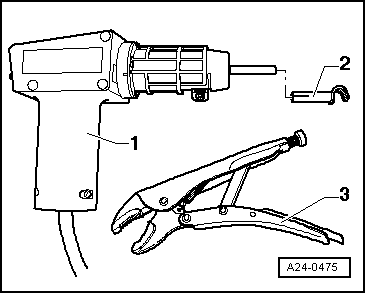

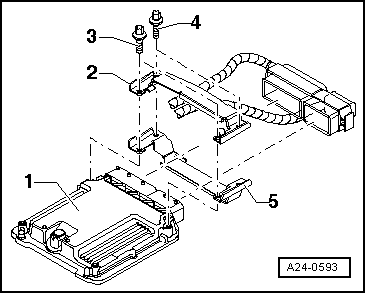

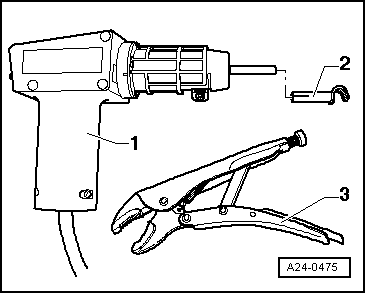

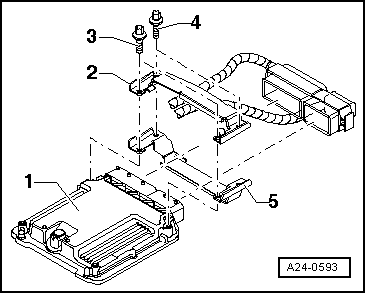

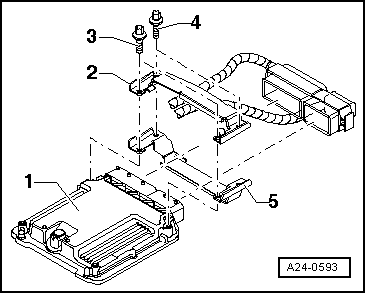

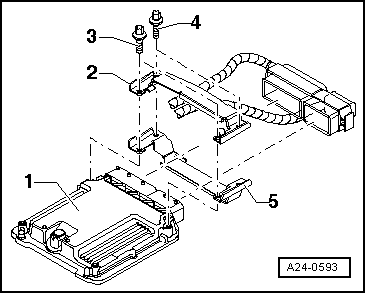

| The two shear bolts screwed into the engine control unit do not need to be heated. They can be removed without heating. |

| –

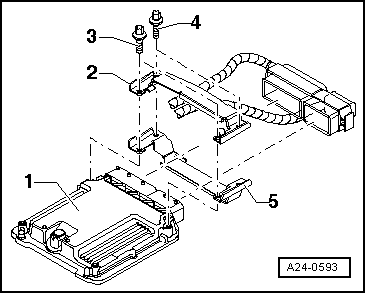

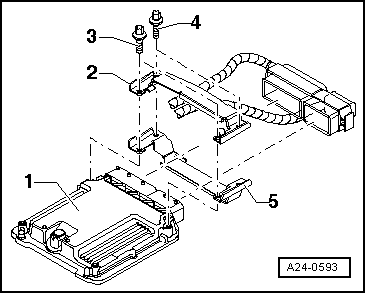

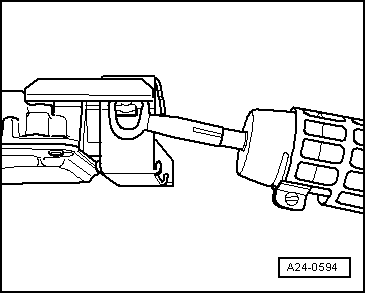

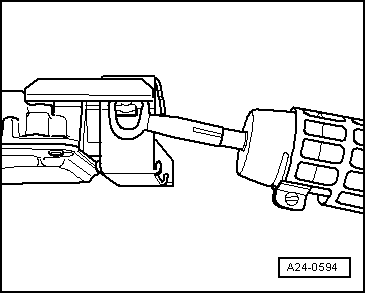

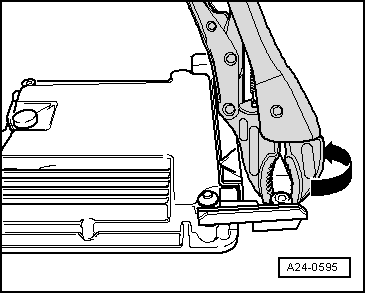

| Detach metal locking plate from control unit connectors. |

| –

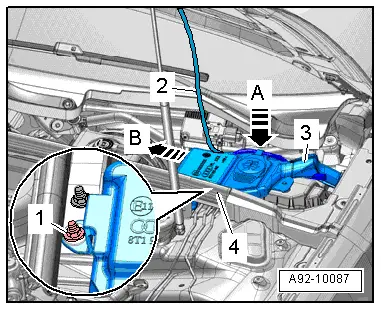

| Release connectors on engine control unit and unplug connectors. |

| –

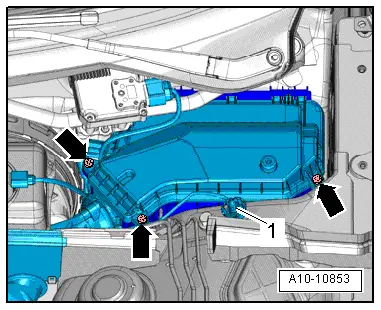

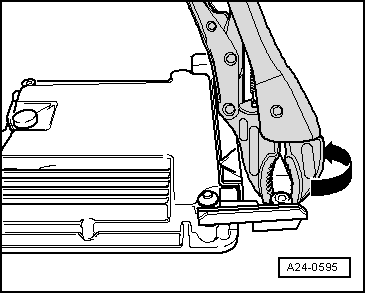

| Take out old engine control unit -J623- and install new engine control unit -J623-. |

| Installation is performed in the reverse sequence. |

| –

| After installation, the locking plate must be re-fitted on the engine control unit -J623-. |

| –

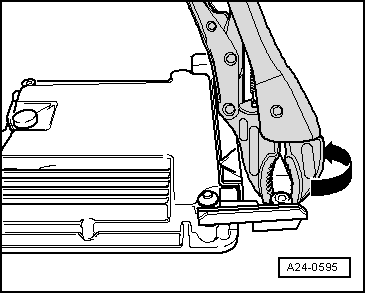

| Clean threaded holes for shear bolts to remove any residue from locking fluid. This can be done using a thread tap. |

| –

| Always use new shear bolts. |

| l

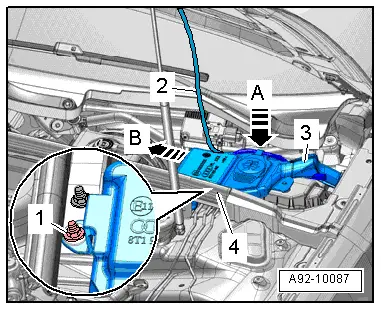

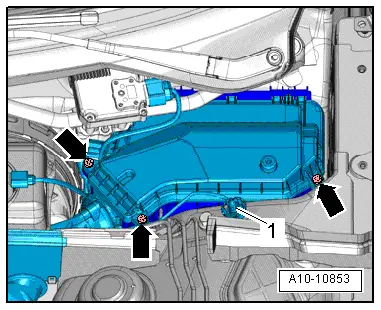

| Tightening torque for bolts securing cover of electronics box: 3.5 Nm. |

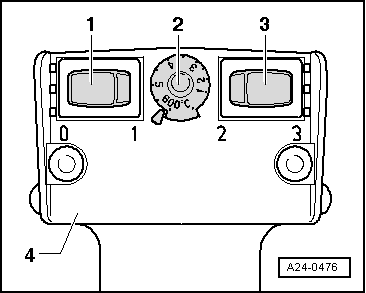

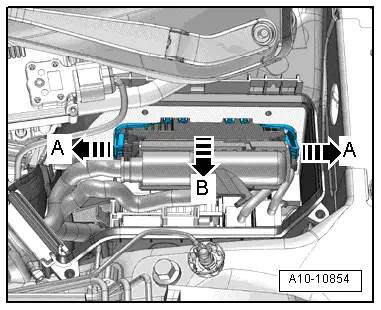

| After installing a new engine control unit, the following operation must be performed: |

| –

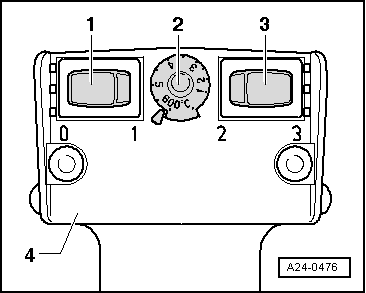

| Activate engine control unit via vehicle diagnostic, testing and information system -VAS 5051B- in “Guided Functions” mode, “Replace engine control unit”. |

|

|

|

Note

Note

Note

Note