A5

Note

Note

|

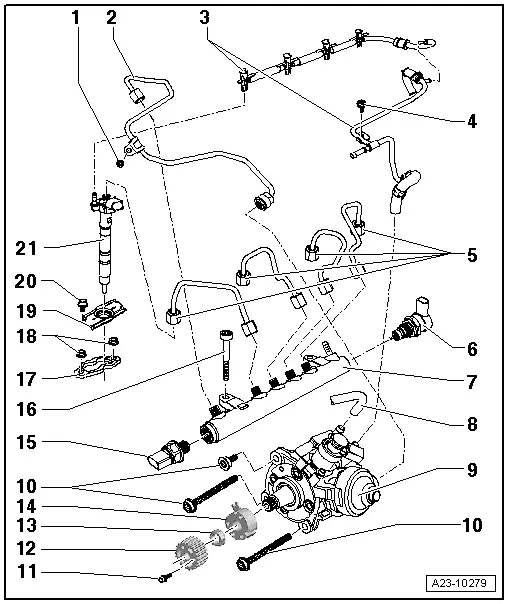

| 1 - | Bolt |

| q | 10 Nm |

| 2 - | High-pressure pipe |

| q | 25 Nm |

| q | Between high-pressure pump and fuel rail |

| 3 - | Fuel return lines |

| q | To fuel tank |

| q | Fuel return line must not be kinked, damaged or clogged |

| q | The fuel return lines must not be dismantled; if necessary they must be renewed complete with pressure retention valve |

| q | The pressure retention valve maintains a residual pressure of approx. 10 bar in the return lines |

| q | This residual pressure is required for the control function of the injectors |

| q | Checking pressure retention valve → Chapter |

| q | After replacement, engine must be run at idling speed for approx. 2 minutes to bleed fuel system. Then check fuel return lines for leaks |

| 4 - | Bolt |

| q | 10 Nm |

| 5 - | High-pressure pipes |

| q | 25 Nm |

| q | Between fuel rail and injectors |

| q | Do not interchange |

| q | Install free of stress |

| 6 - | Fuel pressure regulating valve -N276- |

| q | 80 Nm |

| q | Cannot be re-installed |

| q | Removing and installing → Chapter |

| 7 - | Fuel rail |

| q | Removing and installing → Chapter |

| 8 - | Fuel supply line |

| 9 - | High-pressure pump |

| q | With fuel metering valve -N290- (do not open) |

| q | After renewing, first fuel filling operation MUST be performed (it is important not to allow pump to run while it is still empty) → Chapter |

| q | Removing and installing → Chapter |

| 10 - | Bolt |

| q | 20 Nm |

| q | Turn long bolts 180° further |

| q | Turn short bolts 90° further |

| 11 - | Bolt |

| q | 20 Nm |

| 12 - | Toothed belt sprocket for high-pressure pump |

| 13 - | Nut |

| q | 95 Nm |

| 14 - | Hub |

| q | With sender wheel |

| q | Use counterhold tool -T10051- to loosen and tighten |

| q | To remove, use puller -T40064- |

| 15 - | Fuel pressure sender -G247- |

| q | 100 Nm |

| q | Removing and installing → Chapter |

| 16 - | Bolt |

| q | 22 Nm |

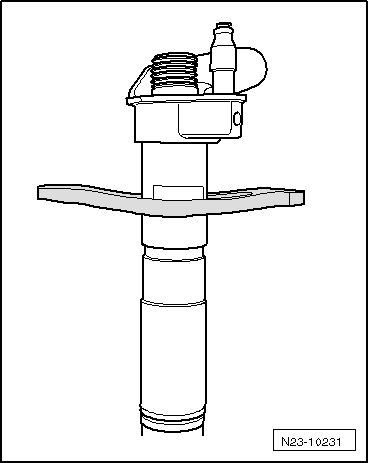

| 17 - | Clamping piece |

| q | If they are to be re-installed, the injectors and clamping pieces must always be re-fitted on the same cylinder. |

| q | When an injector is renewed, the corresponding clamping piece must be renewed at the same time |

| 18 - | Hexagon flange nut |

| q | For clamping piece |

| q | 10 Nm |

| 19 - | Cover for injector |

| 20 - | Bolt |

| q | 5 Nm |

| 21 - | Injector |

| q | If they are to be re-installed, the injectors, high-pressure fuel pipes and clamping pieces must always be re-fitted in their original positions (i.e. on the same cylinder). |

| q | Removing and installing → Chapter |

|

|

WARNING

WARNING Caution

Caution