A5

|

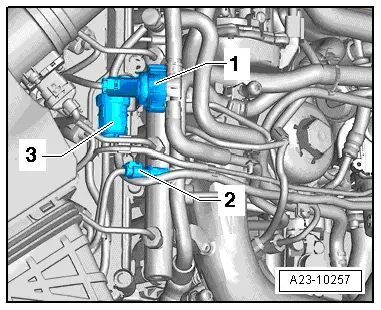

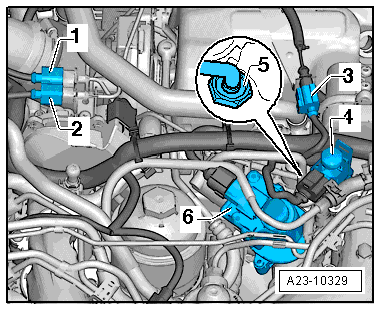

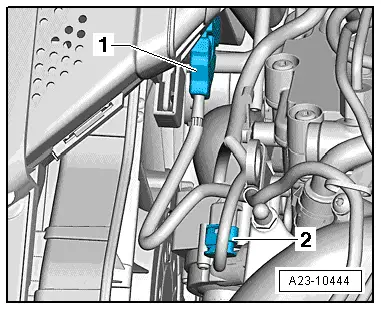

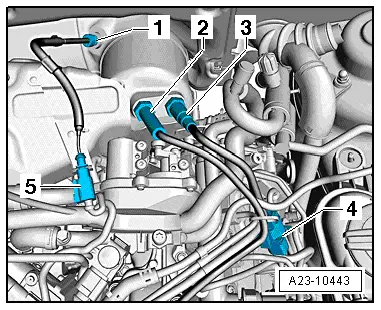

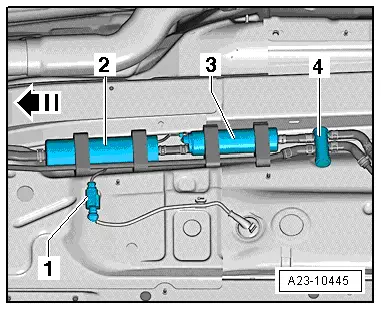

| 1 - | Hall sender -G40- |

| q | Fitting location → Fig. |

| 2 - | Pressure differential sender -G505- |

| q | Fitting location → Fig. |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Chapter |

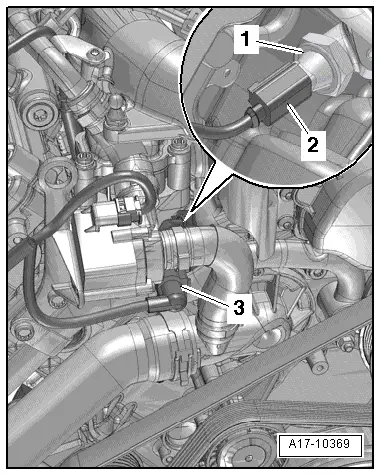

| 3 - | Fuel pressure regulating valve -N276- |

| q | Fitting location → Fig. |

| q | After renewing high-pressure pump or fuel pressure regulating valve -N276-, learnt values must be re-adapted; see „Guided Functions“ in vehicle diagnostic tester |

| q | Removing and installing → Chapter |

| 4 - | Electrical connector |

| For exhaust gas temperature sender 4 -G648- |

| 5 - | Coolant temperature sender -G62- |

| q | Removing and installing → Rep. gr.19 |

| 6 - | Electrical connector for exhaust gas temperature sender 1 -G235- |

| q | Fitting location → Fig. |

| 7 - | Control unit for turbocharger 1 -J724- |

| q | Fitting location → Fig. |

| 8 - | Electrical connector for exhaust gas recirculation temperature sensor -G98- |

| q | Fitting location → Fig. |

| 9 - | Exhaust gas temperature sender 3 -G495- |

| q | Fitting location → Fig. |

| 10 - | Turbocharger |

| q | Removing and installing → Rep. gr.26 |

| 11 - | Intake manifold flap motor -V157- |

| q | Fitting location → Fig. |

| q | Cylinder bank 1 |

| q | Intake manifold - exploded view → Chapter |

| 12 - | NOx sender -G295- |

| q | Fitting location → Fig. |

| 13 - | Lambda probe -G39- |

| q | Fitting location → Fig. |

| 14 - | Electrical connector for exhaust gas temperature sender 3 -G495- |

| 15 - | Intake manifold flap 2 motor -V275- |

| 16 - | Exhaust gas recirculation temperature sensor -G98- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.26 |

| 17 - | Exhaust gas recirculation cooler change-over valve -N345- |

| q | Fitting location → Fig. |

| 18 - | Exhaust gas recirculation control motor -V338- |

| q | Fitting location → Fig. |

| 19 - | Fuel temperature sender -G81- |

| q | Fitting location → Fig. |

| 20 - | Pressure retention valve |

| q | Fitting location → Fig. |

| q | In return lines from cylinder banks 1 and 2 |

| q | The pressure retention valve maintains a residual pressure of approx. 10 bar in the return lines |

| q | This residual pressure is required for the control function of the piezo injectors |

| q | The pressure retention valve may only be renewed together with the fuel return lines |

| q | After replacement, engine must be run at idling speed for approx. 2 minutes to bleed fuel system |

| q | Checking pressure retention valve → Chapter |

| 21 - | High-pressure fuel pump |

| q | With fuel metering valve -N290- |

| q | After renewing high-pressure pump, first fuel filling operation MUST be performed (it is important not to allow pump to run while it is still empty) → Chapter |

| q | After renewing high-pressure pump or fuel pressure regulating valve -N276-, learnt values must be re-adapted; see „Guided Functions“ in vehicle diagnostic tester |

| q | High-pressure pump - exploded view → Chapter |

| q | Removing and installing → Chapter |

| 22 - | Fuel metering valve -N290- |

| 23 - | Oil pressure switch for reduced oil pressure -F378- |

| q | Fitting location → Fig. |

| q | Removing, installing and testing → Rep. gr.17 |

| 24 - | Pump for exhaust gas recirculation cooler -V400- |

| q | Fitting location → Fig. |

| 25 - | Control unit for NOx sender -J583- |

| q | Fitting location → Fig. |

| 26 - | Radiator outlet coolant temperature sender -G83- |

| q | Fitting location → Fig. |

| 27 - | Injectors (piezo injectors) |

| q | Cylinder bank 1 |

| q | Removing and installing → Chapter |

| 28 - | Air mass meter -G70- |

| q | Removing and installing → Chapter |

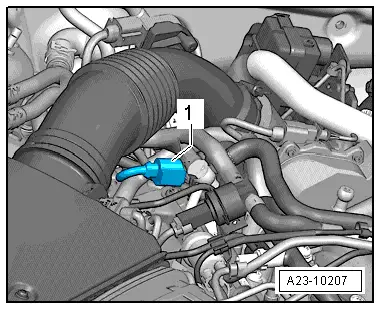

| 29 - | Air filter bypass flap valve -N275- |

| q | These components (bypass flap with air filter bypass flap valve -N275-) are not installed on certain equipment versions or on vehicles for certain export markets |

| q | If fitted, the bypass flap is located in the air cleaner housing and the air cleaner bypass flap valve -N275- is located on the outside of the air cleaner housing |

| q | Air cleaner - exploded view → Chapter |

|

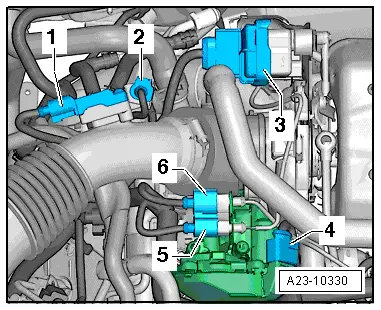

| 1 - | Exhaust gas temperature sender 3 -G495- |

| q | Fitting location → Fig. |

| 2 - | NOx sender -G295- |

| q | Fitting location → Fig. |

| 3 - | Lambda probe -G39- |

| q | Fitting location → Fig. |

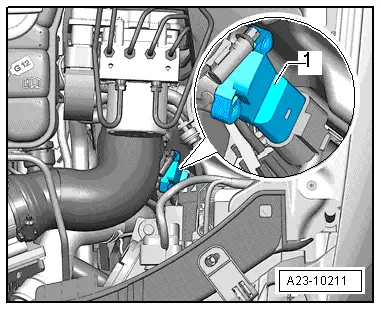

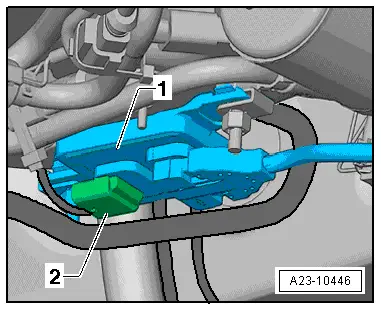

| 4 - | Engine control unit -J623- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| 5 - | Charge pressure sender -G31- |

| q | With intake air temperature sender -G42- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.21 |

| 6 - | Throttle valve module -J338- |

| q | 9 Nm |

| 7 - | Injectors (piezo injectors) |

| q | Cylinder bank 2 |

| q | Removing and installing → Chapter |

| 8 - | Fuel pressure sender -G247- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| 9 - | Connector for Lambda probe -G39- |

| q | Fitting location → Fig. |

| 10 - | High-pressure fuel pump |

| q | With fuel metering valve -N290- |

| q | After renewing high-pressure pump, first fuel filling operation MUST be performed (it is important not to allow pump to run while it is still empty) → Chapter |

| q | After renewing high-pressure pump or fuel pressure regulating valve -N276-, learnt values must be re-adapted; see „Guided Functions“ in vehicle diagnostic tester |

| q | High-pressure pump - exploded view → Chapter |

| q | Removing and installing → Chapter |

| 11 - | Fuel metering valve -N290- |

| 12 - | Exhaust gas recirculation control motor -V338- |

| q | Fitting location → Fig. |

| 13 - | Exhaust gas recirculation cooler change-over valve -N345- |

| q | Fitting location → Fig. |

| 14 - | Exhaust gas recirculation temperature sensor -G98- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.26 |

| 15 - | Electrical connector for exhaust gas temperature sender 3 -G495- |

| 16 - | Intake manifold flap 2 motor -V275- |

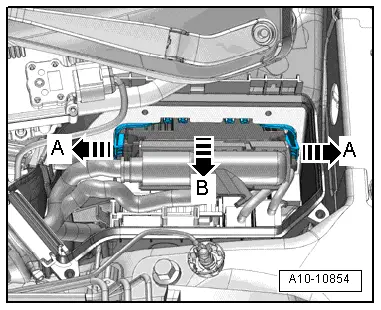

| A - | Relay and fuse holder in electronics box in plenum chamber (left-side) |

| q | Removing and installing engine control unit -J623- with altitude sensor → Chapter |

| q | Fitting locations → Current flow diagrams, Electrical fault finding and Fitting locations |

| B - | Low heat output relay -J359- and high heat output relay -J360- |

| q | Fitting locations → Current flow diagrams, Electrical fault finding and Fitting locations |

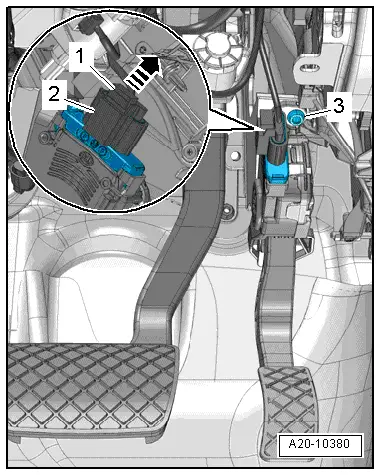

| C - | Brake light switch -F- and brake pedal switch -F47- |

| q | In footwell on brake pedal |

| D - | Accelerator position sender -G79- and accelerator position sender 2 -G185- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.20 |

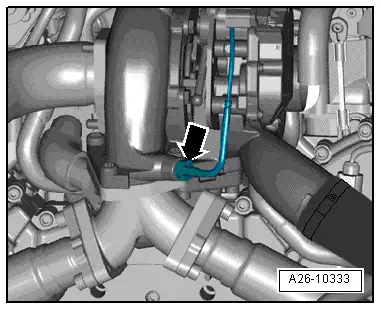

| E - | Exhaust gas temperature sender 1 -G235- |

| q | On turbocharger |

| q | 45 Nm |

| q | Removing and installing → Rep. gr.26 |

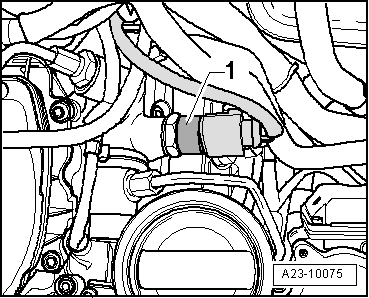

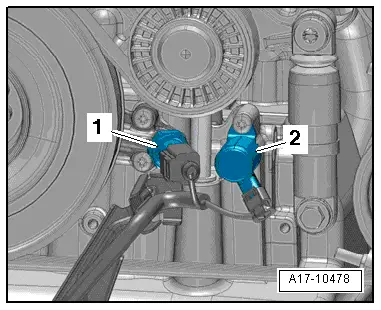

| F - | Engine speed sender -G28- |

| q | Fitting location → Fig. |

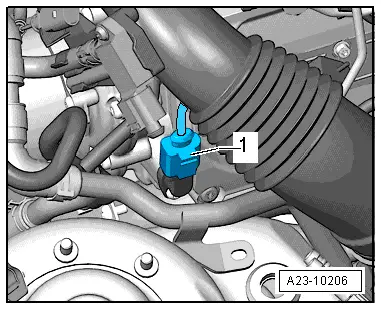

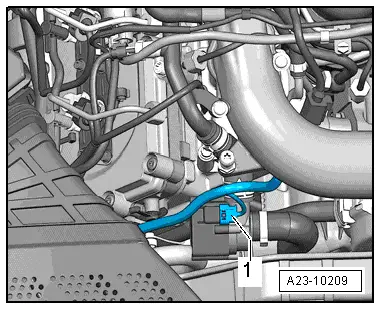

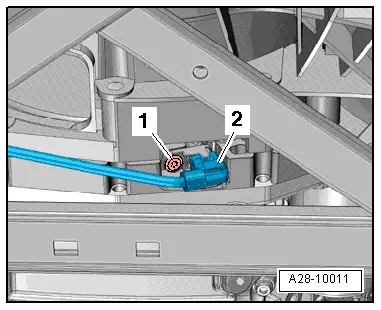

| G - | Supplementary fuel pump -V393- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.20 |

| H - | Oil pressure switch -F22- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.17 |

| I - | Valve for oil pressure control -N428- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.17 |

| J - | Glow plugs |

| q | Glow plug 1 -Q10- |

| q | Glow plug 2 -Q11- with cylinder 2 combustion chamber pressure sender -G678- |

| q | Glow plug 3 -Q12- |

| q | Glow plug 4 -Q13- |

| q | Glow plug 5 -Q14- with cylinder 5 combustion chamber pressure sender -G681- |

| q | Glow plug 6 -Q15- |

| q | Removing and installing → Chapter |

| K - | Particulate filter |

| q | Fitted on underbody |

| q | Combined with a catalytic converter |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Rep. gr.26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|